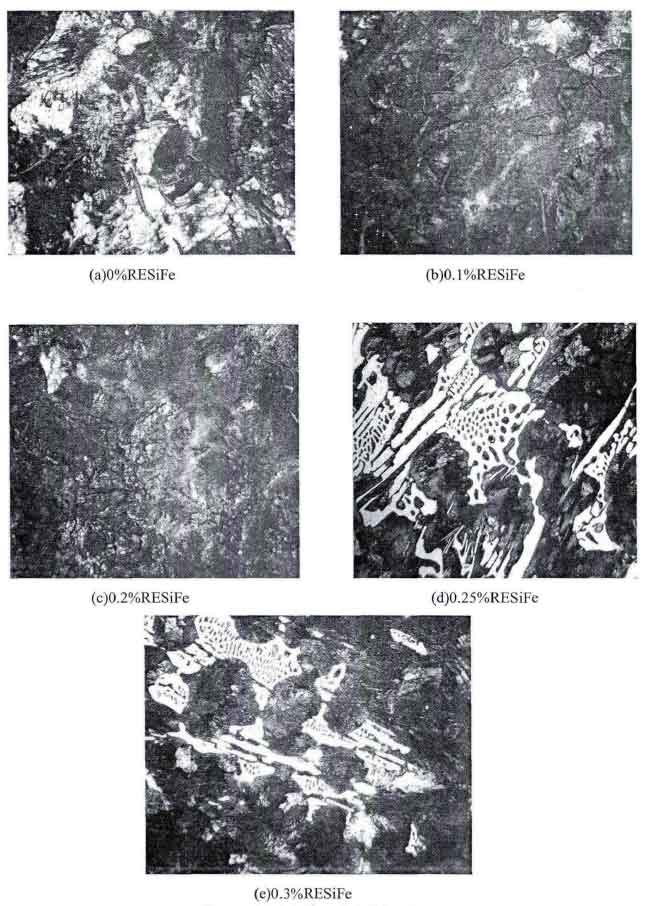

By comparing the matrix structure of low carbon equivalent gray cast iron treated with different rare earth additions, it can be found (as shown in the figure):

- There are a large number of primary cementite in the matrix of the sample injected with raw molten iron, which shows that the low-carbon equivalent gray cast iron has a great tendency of white cast iron. This can also be seen from the triangular test piece, which also shows that the low-carbon equivalent gray cast iron must be inoculated before it can be applied.

- When 0.1% rare earth ferrosilicon alloy is added, the number of cementite is greatly reduced and the number of pearlite is increased, indicating that the rare earth alloy plays an obvious role in promoting graphitization and forming inoculation effect.

- When 0.2% rare earth ferrosilicon alloy is added, the matrix is pearlite with a small amount of ferrite and a very small amount of cementite. At this time, the rare earth alloy still has the inoculation effect of promoting graphitization.

- When 0.25% rare earth ferrosilicon alloy is added, a large number of ledeburite appears, indicating that the rare earth alloy has an obvious effect of hindering graphitization, resulting in a great undercooling tendency of low carbon equivalent gray cast iron.

- When 0.3% rare earth ferroalloy is added, a large amount of ledeburite structure continues to appear in the structure of gray cast iron. Due to the spheroidization and spiration of graphite, the amount of ferrite increases and the amount of ledeburite decreases compared with the former.