By studying the microstructure of bimetallic composites, it is found that:

1). The interface affects the service life of bimetallic castings. Whether metallurgical bonding can be formed between two metal materials is the key basis to judge the quality of composite interface. The microstructure of the transition region shows that the two metals are combined continuously, evenly and compactly; When the alloy steel is poured after pouring, the surface of the low-carbon steel has solidified and crystallized, but the high-temperature molten iron will dissolve. It is on the surface of the low-carbon steel under the solid-state line, which belongs to solid-liquid combination. The dense structure confirms that the interface is in the state of metallurgical combination without any mixing phenomenon.

2). The energy spectrum analysis results of the interface show that the scanning from the alloy steel to the low carbon steel shows that the active elements near the interface diffuse under the action of concentration drive, power drive and temperature drive, and show a gradient distribution in the region. The chromium element in the alloy steel diffuses to the low concentration side, and the chromium element concentration in the transition region decreases from right to left.

3) The interfacial mechanical properties of materials are determined by the thickness of the bonding layer of two metals. The composite of the two materials is realized by short-distance diffusion and infiltration. SEM observation results show that the interface transition region is about dozens of microns, the shape is relatively flat, and the alloy elements show gradient changes in the transition region. The low-carbon steel is basically solidified after pouring, and then the high-temperature alloy steel is poured to form a molten thin layer on the low-carbon steel, which will remain liquid for a certain period of time to avoid oxidation on the surface of the low-carbon steel. With the gradual cooling, as the steel and iron are infiltrating each other, the alloy steel and the melt thin layer nucleate, crystallize and grow on the surface of the low carbon steel in turn, and finally realize the metallurgical combination.

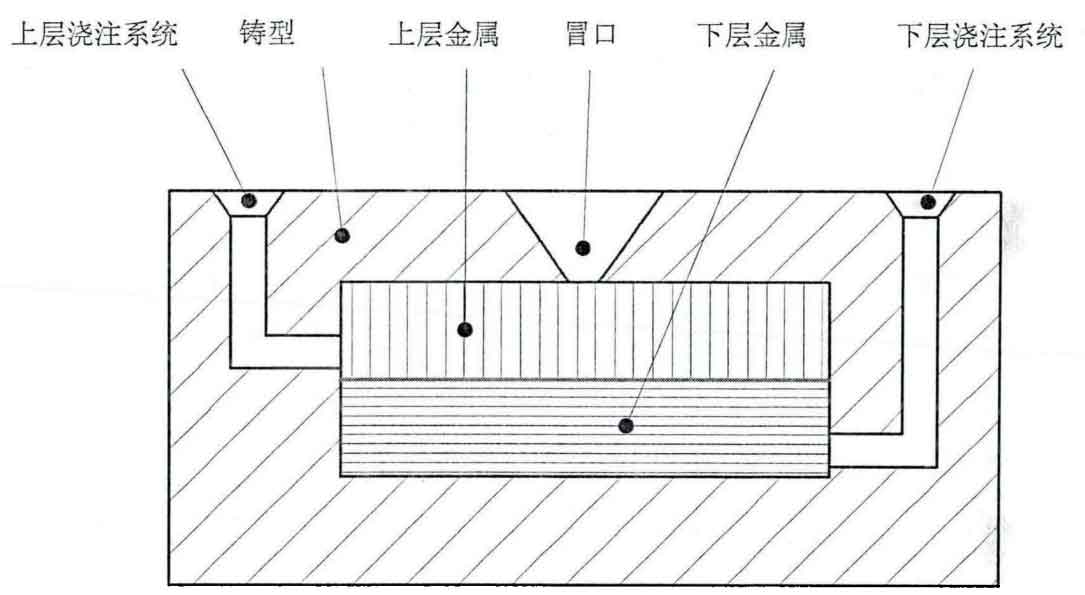

The research shows that the process modeling and injection system of double liquid horizontal re injection without diaphragm are simple, the pouring temperature and interval time of the two metals are well controlled, the metallurgical combination of strong, tough and wear-resistant materials is realized, the transition interface is staggered, and the component diffusion is reasonable. The bi metal wear-resistant castings with high directivity and excellent wear-resistance can be prepared, which are not easy to deform and easy to load and unload, It overcomes the shortcomings of traditional single wear-resistant material castings such as high strength steel, and has good comprehensive properties.