Take out large bimetallic samples from the upper plate of high chromium cast iron and carbon steel bimetallic lining with an electric saw, and then cut out impact samples, bending strength samples, metallographic samples and heat treatment samples with a wire cutting machine.

Microcomputer controlled electronic universal testing machine, pendulum impact testing machine, Rockwell hardness tester, microhardness tester, optical microscope, scanning electron microscope, energy dispersive X-ray spectrometer and X-ray diffraction analyzer were used in the test.

1.Impact toughness and bending strength test

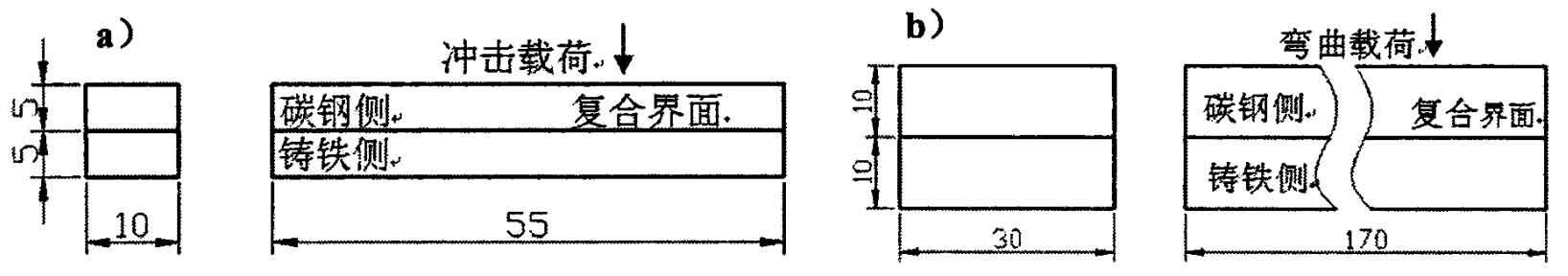

The upper and lower areas of the composite interface were taken, and the impact samples and bending samples containing the composite interface were manufactured by wire cutting. The impact and bending loads were applied to the high chromium cast iron layer. Conduct impact test on the impact test machine with a size of 10mmx10mmx55mm without notch, and measure the impact toughness value of the sample α k. The notchless impact specimen with the size of 20mmx30mmx170mm was tested on the microcomputer controlled electronic universal testing machine for bending strength; See Figure 1 for details.

For the impact toughness test of composite materials, the impact load parallel to the composite interface is usually applied. In fact, the test process of impact toughness is to verify the bonding strength of the two materials on the composite interface through the shear force parallel to the interface. However, considering the load conditions of the bimetallic liner in service, the impact load is applied in the direction perpendicular to the composite interface.

2.Hardness test

The wear resistance of high chromium cast iron depends on the surface hardness of the material, so hardness test is an important content to evaluate the mechanical properties of high chromium cast iron and carbon steel bimetallic liner. In addition, in order to study the properties of the interface diffusion transition zone between high chromium cast iron and carbon steel, it is also very important to test the microhardness of the area near the interface. In this test, the samples were cut by wire cutting process. The high chromium cast iron was tested by Rockwell hardness tester for Rockwell hardness (HRC), and the microstructure near the interface was tested by microhardness tester for microhardness (HV). The applied load was 1.98n‘

3.Microstructure test

The large sample of bimetallic lining plate is cut into 12mmx12mmx12mm small sample blocks by wire cutting, which are polished and polished with coarse, medium and fine diamond sandpaper respectively, and the solution corrosion candle is prepared with ferric chloride, 20ml hydrochloric acid and 20ml ethanol. This corrosion candle liquid can well corrode the matrix structure except carbonates, and the composition and morphological distribution of different phase structures can be clearly observed under the microscope.

The phase composition of samples before and after heat treatment was detected by X-ray diffraction analyzer.

4.Heat treatment process

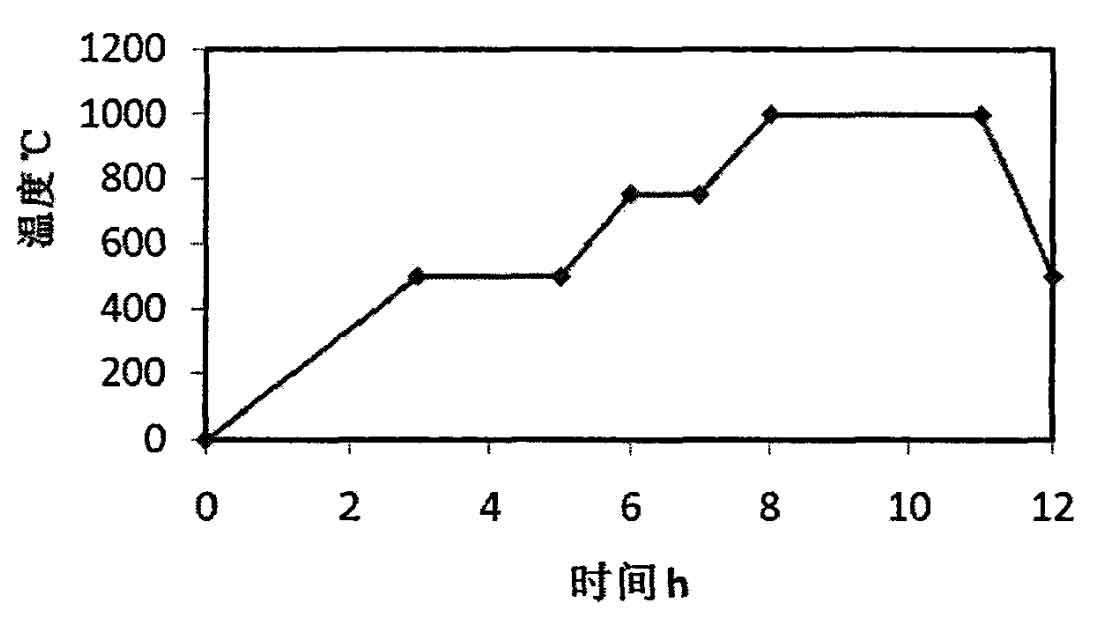

The heat treatment process of bimetal composite sample mainly refers to the destabilization heat treatment process of high chromium cast iron, which includes destabilization control during austenitizing and air cooling quenching. As shown in Figure 2, the step heating heat treatment process is used to avoid interface cracking of high chromium cast iron carbon steel bimetal sample caused by improper quenching process.