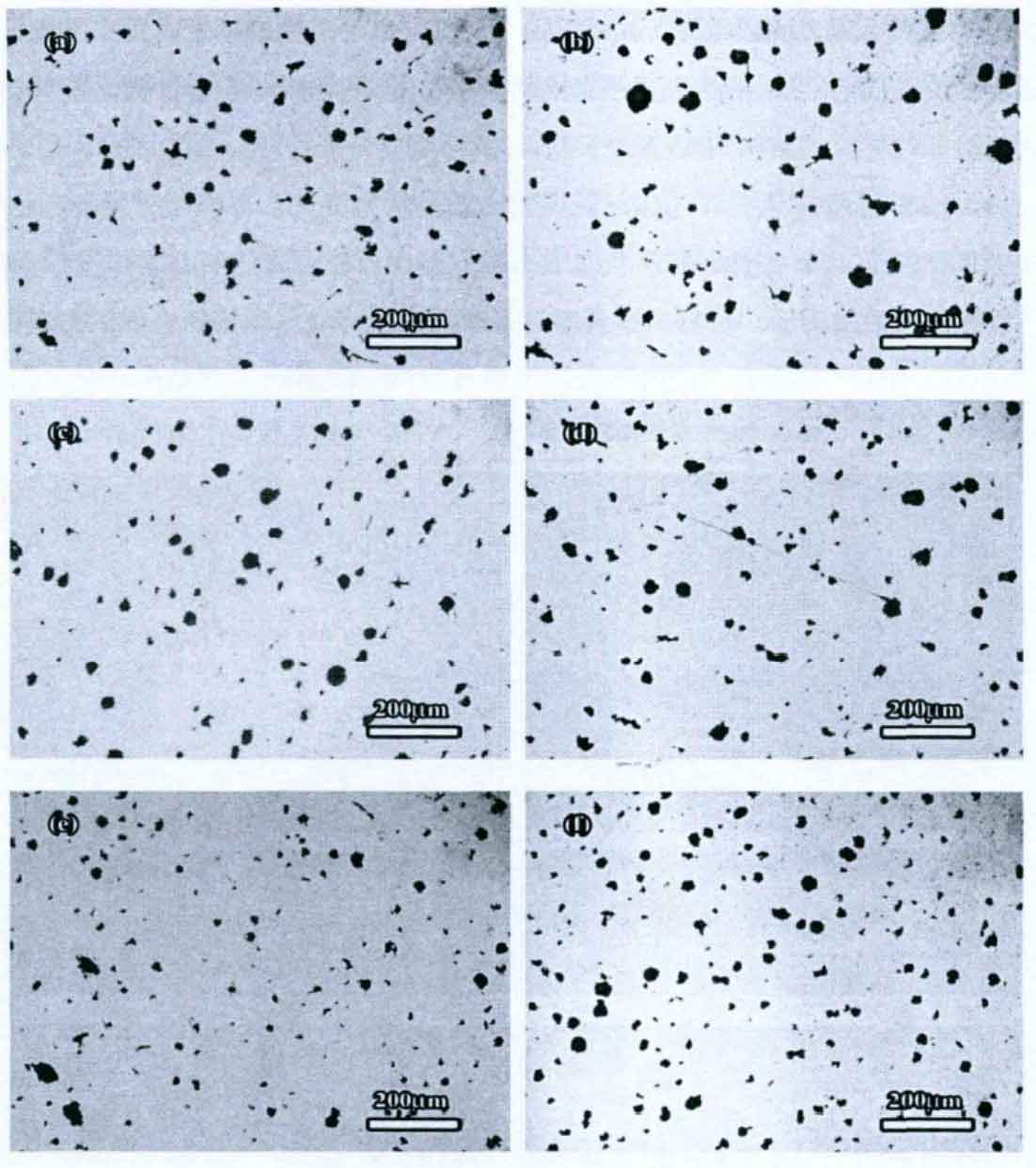

Figure 1 shows the graphite morphology of the nodular cast iron by vibration lost foam casting, in which figure 1 (a) – (f) shows the graphite morphology at the wall thickness of 10, 20, 30, 40, 50 and 60mm respectively. It can be seen from the figure that the amount of distorted graphite is large in both the samples with large wall thickness and the samples with small wall thickness.

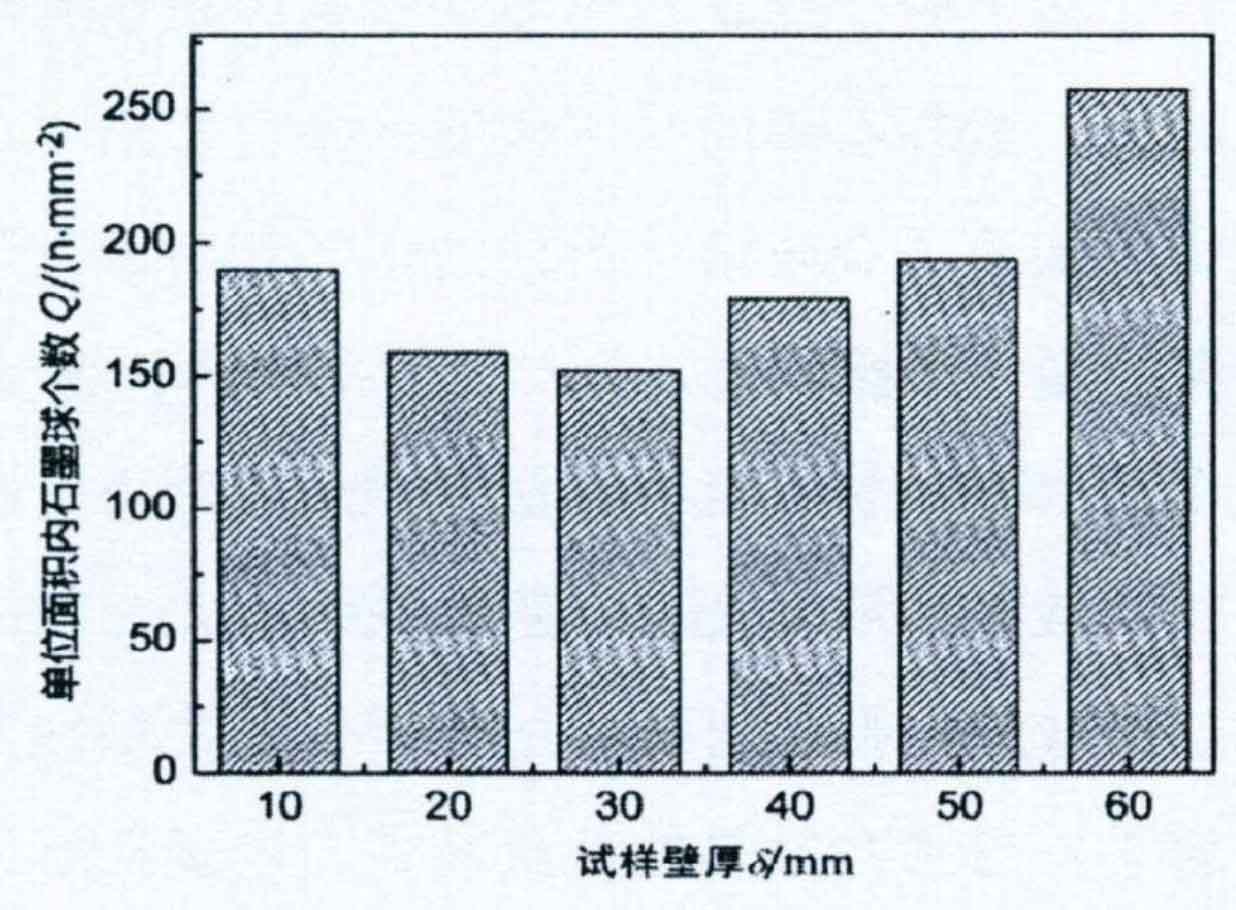

Figure 2 shows the statistical results of the number of graphite balls per unit area in samples with different wall thickness. It can be seen from the figure that the number of graphite balls per unit area first decreased from 190 in 10mm samples to 152 in 30mm thick samples, and then gradually increased to 257 in 60mm thick samples. Among the samples with 60mm wall thickness, the number of graphite balls per unit area is the most, while the number of graphite balls per unit area is the least among the samples with 30mm wall thickness.

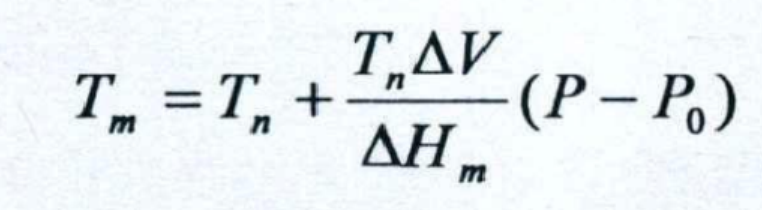

When the sample wall thickness is moderate, vibration solidification can increase the number of graphite balls per unit area in nodular cast iron (as shown in Figure 1). This is because the application of vibration promotes the rapid collapse and disappearance of defects such as vacancies in prayer pieces. When the hole collapse disappears, the hall around the hole will quickly occupy the position of the hole, which will increase the pressure near the hole. According to Clapeyron formula:

The number of graphite spheres per unit area in nodular cast iron decreases first and then increases with the increase of sample wall thickness. This is because with the increase of sample wall thickness, the volume of nodular cast iron is increased, the heat storage capacity inside the casting is increased, the solidification time of the casting is prolonged, and the cooling rate of the casting is reduced. The nodularizing agent contacts with the metal flame for a long time, which intensifies the nodularization recession, thus reducing the nodularization rate of nodular cast iron. When the sample wall thickness is small (less than or equal to 30mm), the increase of sample wall thickness increases the decline of spheroidizing agent, and there is no new nucleation core to supplement, resulting in the reduction of the number of spherical graphite per unit area. The number of spheroidal graphite per unit area increases with the increase of sample wall thickness. This is because the action time of vibration on the metal solution and the metal solution in the solid-liquid mixing zone is prolonged, and the deposition of carbon atoms in the metal culture on the surface of graphite nuclei is restrained. At the same time, the vibration can destroy the primary phase and increase the number of graphite nuclei in the metal flame and the number of spherical graphite per unit area in the ductile iron castings.