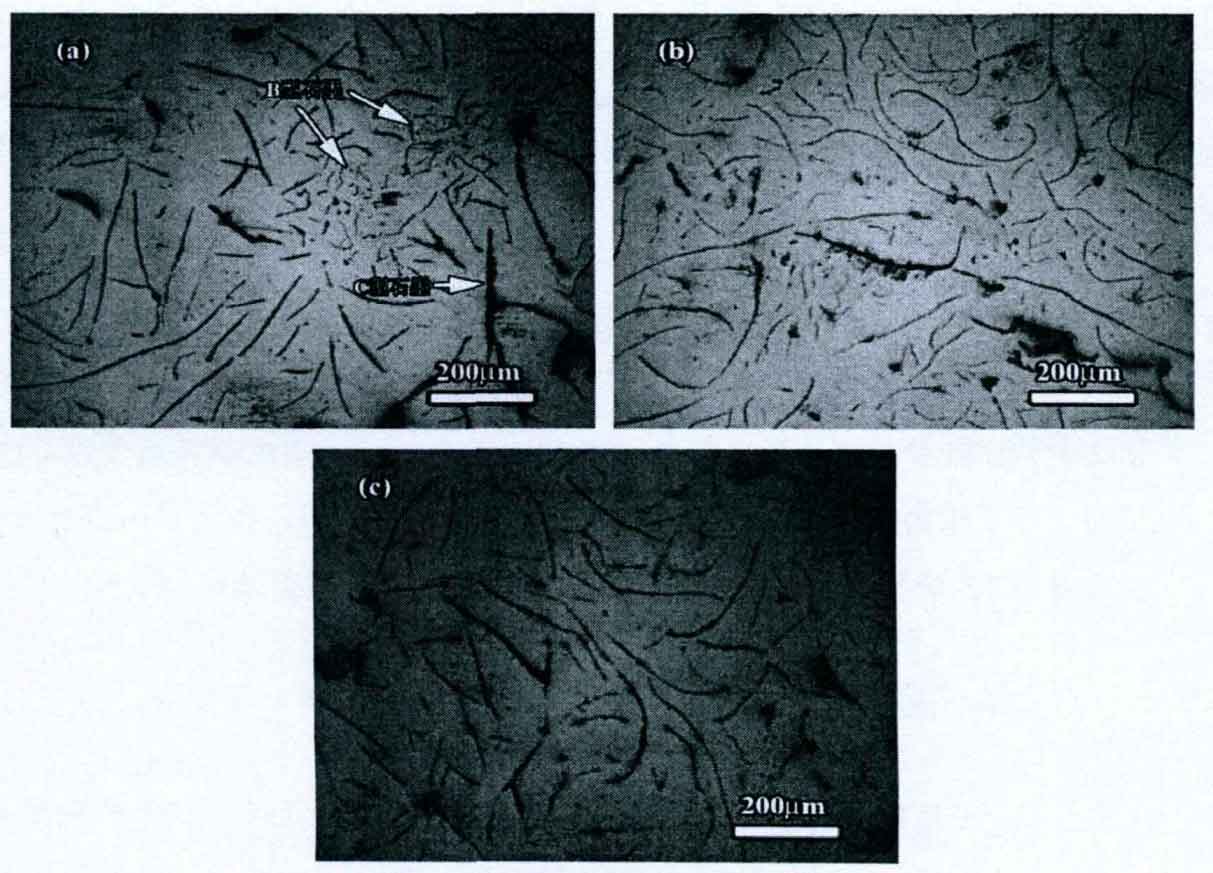

The figure shows the graphite morphology in gray cast iron with different wall thickness. Among them, figures (a) – (c) show the graphite morphology at the center of the 20mm, 40mm and 60mm stepped samples respectively.

It can be seen from the figure that when the wall thickness of the casting is small (20mm), the graphite type is mainly A-type flake graphite, containing a small amount of B-type chrysanthemum graphite and C-type graphite; When the wall thickness increases, the B-type graphite in cast iron disappears, and the graphite type is mainly A-type flake graphite. In addition, it also contains a small amount of C-type graphite.

Through comparison and analysis, it can be seen that the length of A-type flake graphite in 40mm and 60mm thick grey cast iron is longer than that of 20mm thick grey cast iron, while the length of A-type flake graphite in 40mm and 60mm thick grey cast iron is similar.

A small amount of type a graphite appears in the cast iron with a wall thickness of 20mm. On the premise of good inoculation, hypoeutectic cast iron with low carbon equivalent will generate pre precipitated austenite in the metal body, which will continue to cool. When the temperature is reduced to the eutectic temperature, the remaining metal solution will undergo Eutectic Transformation, forming a eutectic structure composed of A-type graphite and eutectic austenite. The reasons for the appearance of B-type graphite in lost foam cast iron with small wall thickness (20mm) include:

- lost foam casting is carried out under negative pressure. The foamed plastic pattern is vaporized under the thermal action of the metal body, and its products are discharged from the mold cavity under the negative pressure. The gas escapes from the mold cavity and takes away a lot of heat at the same time, which increases the cooling rate at the early solidification stage of lost foam casting gray cast iron and promotes the formation of B-type graphite in gray cast iron.

- when the metallographic lattice with low carbon equivalent begins to solidify, a large amount of austenite will precipitate. At this time, the graphite nucleation conditions are poor. In addition, when the sample wall thickness is small (20mm), its cooling speed is accelerated, the undercooling of the metal melt is large, and it is easy to generate fine graphite.

From the above analysis, it can be seen that the solidification conditions of the gray cast iron with wall thickness meet the formation conditions of forming graphite, so fine graphite is formed in the gray cast iron with wall thickness, which grows rapidly in the eutectic stage and forms radial shaped graphite. At the later stage of solidification, the metal liquid releases the latent heat of solidification, and the undercooling of the metal flame decreases, and the B-type flake graphite precipitates.

In the gray cast iron with larger wall thickness, the solidification rate of gray cast iron becomes slower, the eutectic solidification time is prolonged, and the undercooling degree is reduced due to more solidification latent heat released by the metal during solidification. These conditions promote the precipitation of A-type flake graphite in the gray cast iron, which is not conducive to the formation of B-type graphite. Therefore, there is no B-type graphite in the gray cast iron with larger wall thickness.

In addition, it can be seen from the figure that C-type graphite appears in three gray cast irons with different wall thickness. This is because lost foam casting adopts dry sand modeling, and the thermal conductivity of dry sand is low. Compared with other casting methods, the cooling speed of lost foam casting cast iron is slow, resulting in the precipitation of C-type graphite in cast iron.