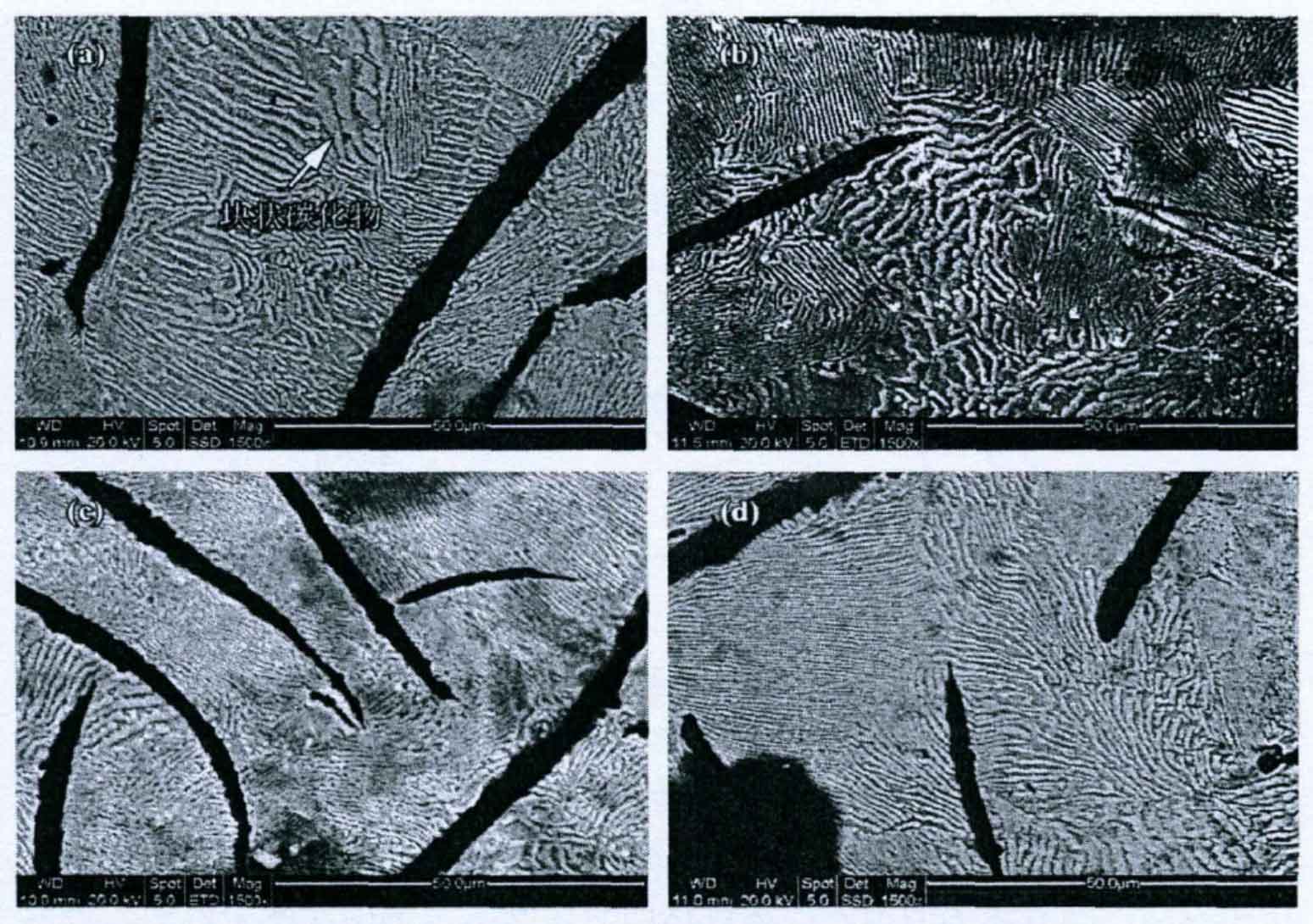

The figure shows the matrix structure of gray cast iron. Among them, figures (a) – (d) are the matrix structure diagrams of gray cast iron prepared under the conditions of amplitude of 0.75, 2, 3 and 4mm respectively.

It can be seen from the figure that the matrix structure of gray cast iron prepared under different amplitude conditions is pearlite + graphite. Comparing the pearlite flake spacing of grey cast iron prepared by several processes, it can be found that when the amplitude is 0.75mm, the pearlite flake spacing of grey cast iron is large, and there is a small amount of massive carbide in the matrix structure, as shown by the arrow in figure (a). When the amplitude is increased to 2mm, the pearlite lamellae spacing in some areas of gray cast iron is larger, and the cementite lamellae in these areas are shorter and thicker; When the amplitude increases to 3mm, the flake spacing of most pearlite in gray cast iron is small, and the flake spacing of pearlite in local areas is large, which is mainly caused by the different cooling rate of each part of the casting. When the amplitude is further increased to 4mm, the flake spacing of some pearlite in gray cast iron increases, and the length of cementite flake is shorter and the thickness is larger. The pearlite of gray cast iron prepared under different amplitudes shows different variation characteristics. This is mainly because the change of amplitude changes the thermodynamic and dynamic conditions in the solidification process of gray cast iron, affects the diffusion and movement of carbon atoms in gray cast iron, and changes the distribution characteristics of pearlite in gray cast iron.