1. Casting process plan

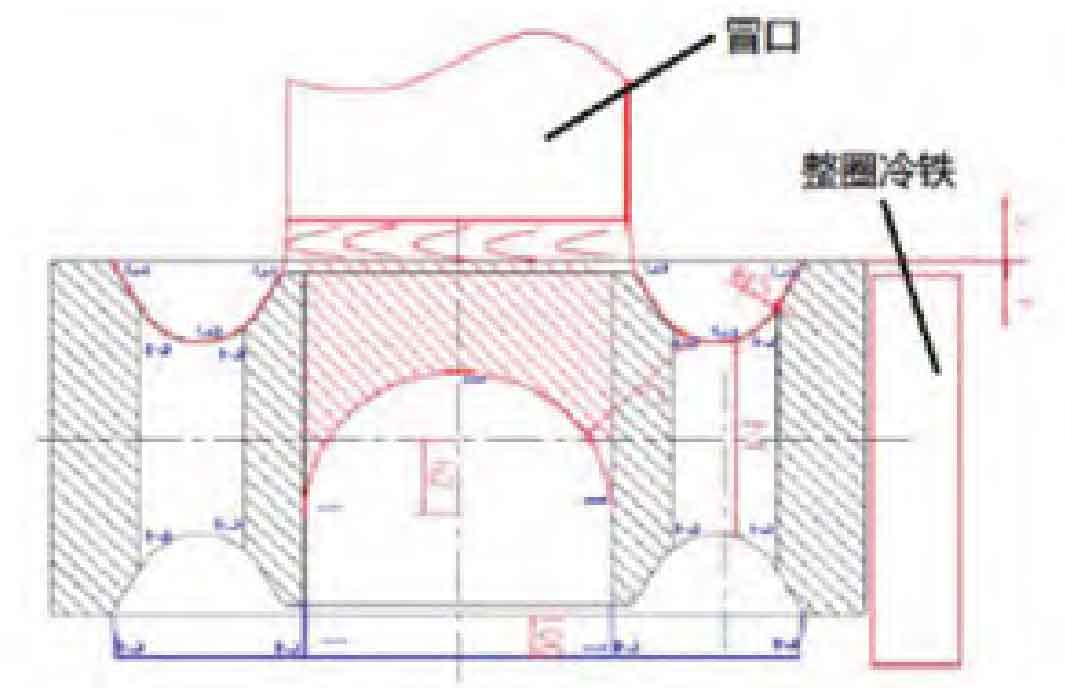

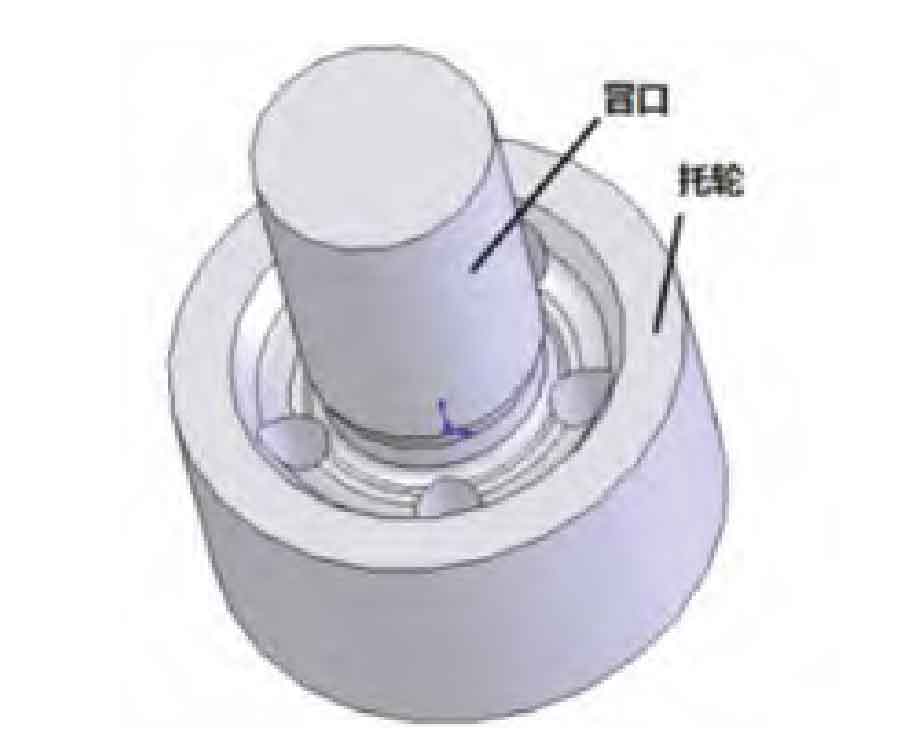

The supporting roller is generally made of ZG42Cr1Mo, ZG35Cr1Mo or similar materials. The hardness of the outer circle is generally about 220~240 HBW. The production process is smelting → casting → heat preservation → sand falling → high temperature annealing after casting → hot cutting riser → stress relief tempering → blank finishing → rough machining → non-destructive testing → (defect repair) → quenching and tempering heat treatment → semi finishing → non-destructive testing → finishing. The casting process plan of the supporting wheel is relatively mature (see Figure 1), and the main contents are as follows:

(1) A single riser is used, and the upper part of the central shaft hole is cast as the feeding channel.

(2) The outer circle is cooled by a whole circle of cold iron to promote the formation of the solidification end. At the same time, the density of the key use surface of the outer circle is improved, so as to improve the fatigue strength and achieve the effect of improving the wear resistance during the running with the tire.

(3) The pouring scheme of corresponding outer rim bottom undercut pouring+re pouring riser is adopted to ensure rapid and stable mold filling in the early stage, improve the temperature gradient of molten steel in the riser in the later stage, and improve the feeding capacity of the riser.

2. Problems

When a factory used the general process plan to produce the supporting rollers, the quality could not be guaranteed to be stable, especially in the production of large supporting rollers, serious defects were often found after rough machining, which even led to scrapping, causing significant losses. The defects mainly include large-area blowhole sand loss, unqualified super detection and cracks, as shown in Figure 2.

When the supporting roller has serious defects, it is made of low-alloy steel, which needs to be quenched and tempered subsequently. Its welding repair process is very complex, requiring high preheating and tempering temperatures after welding. At the same time, in order to ensure that the flaw detection and hardness of the welding repair area are qualified, the welder’s operating skills are very strict. Enterprises need to invest a lot of manpower and material resources to repair welding, which seriously affects the normal production process. When the supporting roller has major crack defects, it can only be scrapped, which seriously affects the economic benefits of the enterprise.