1. Main structural characteristics of vertical column

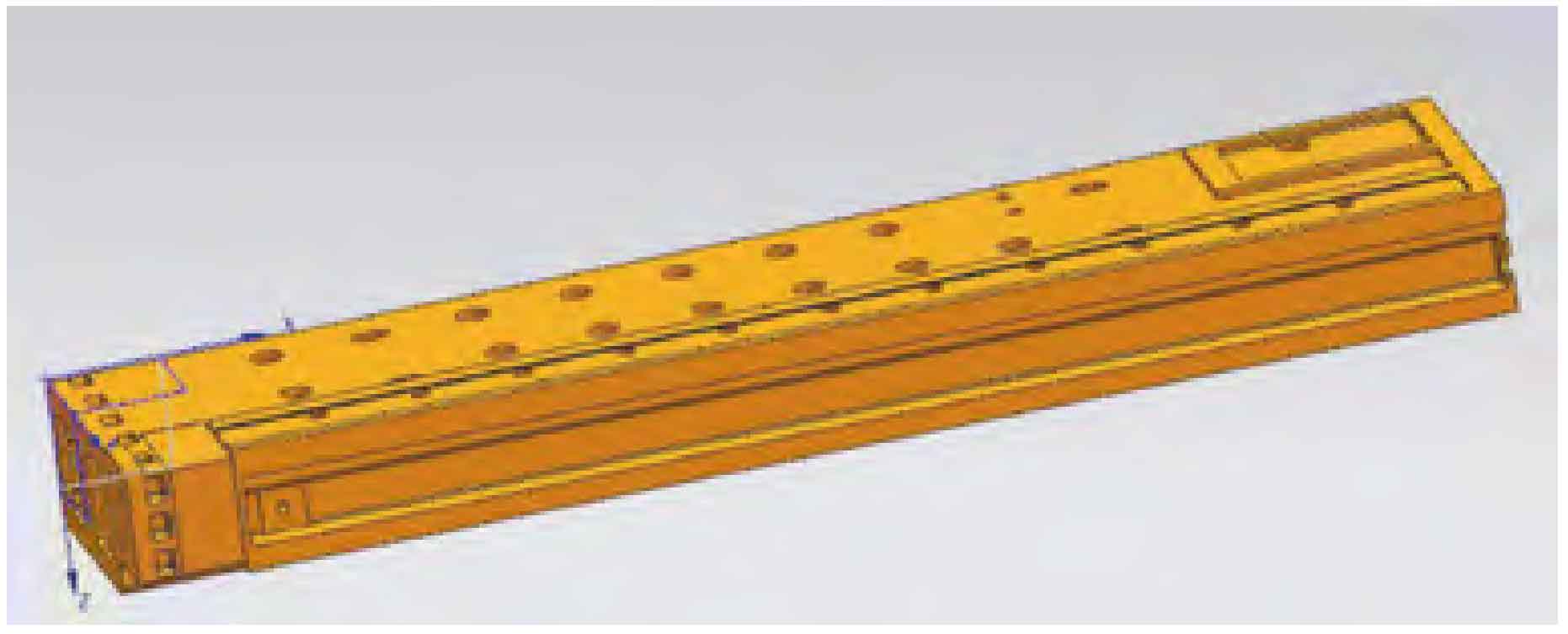

The vertical lathe column casting is a super large, super heavy and high-strength gray iron casting with multi-layer structure, high strength, large outline size, long processing journey, uneven wall thickness and great production difficulty. In the casting process, the volume is large, the structure is complex, the amount of molten iron poured is large, the cooling time of the casting is long, and the casting defects such as shrinkage cavity, porosity, porosity, cracks, and mechanical properties are not up to standard are easy to occur, and the production process control is difficult. Therefore, higher requirements are put forward for process design. According to the author, the overall dimension is 11 000 mm × 2 600 mm × 1 250 mm, net weight 42 750 kg, gross weight 46 500 kg, minimum wall thickness 35 mm, maximum wall thickness 154 mm vertical lathe column casting is taken as an example for research, and its structure is shown in the figure.

2. Technical requirements for vertical column castings

The material of the casting is HT250, the hardness of the guide rail of the column casting is 180~230 HBW, and the guide rail surface of the column casting is free of shrinkage cavity, crack, sand hole, sand inclusion and other casting defects.