According to the structural characteristics of sand casting for vertical column and the technical requirements of main guide rail surface, the process analysis and design are carried out from the aspects of molding materials and modeling methods, the processability of sand casting, the selection of parting position, the design of sand core, and the design of gating system.

1. Modeling materials and modeling methods

(1) Modeling materials

The column is molded and cored with furan resin sand. Resin bonded sand casting has the advantages of high dimensional accuracy and good surface finish, but at the same time, there are also problems such as easy to stick sand, easy to appear air holes, especially for large sand castings with large amount of molten iron and long solidification time.

Therefore, it is necessary to control the quality of reclaimed sand, increase the air exhaust of sand mold and reduce the air generation of sand mold.

(2) Modeling method

According to the structural characteristics, size and actual production conditions of the column, the pit sample modeling is adopted.

2. Process analysis of sand castings

After analyzing the sand casting process of the column, it is found that the structure at the right angle on the back of the column is easy to crack. It is suggested that the designer adopt a bevel transition. At the same time, at the place where the wall thickness changes sharply, process tie bars are added to prevent cracks.

The casting numerical simulation is used to analyze the causes of shrinkage cavity, shrinkage porosity and other defects in the thick parts of sand castings and guide rail surface, optimize the design of gating system, riser and chill, ensure the cooling balance of each part of sand castings, reduce the sand casting stress, and prevent the sand castings from cracks, shrinkage cavity and shrinkage porosity.

3. Selection of parting surface of sand casting

The determination of parting surface shall consider: the surface with high quality requirements shall be placed below or on the side; The large plane of sand casting shall be placed below; It is beneficial to directional solidification of sand castings and easy to place feeding risers; The sand castings shall be placed in the same sand mold as far as possible to reduce the flapping and box staggering and ensure the size and appearance quality of the sand castings.

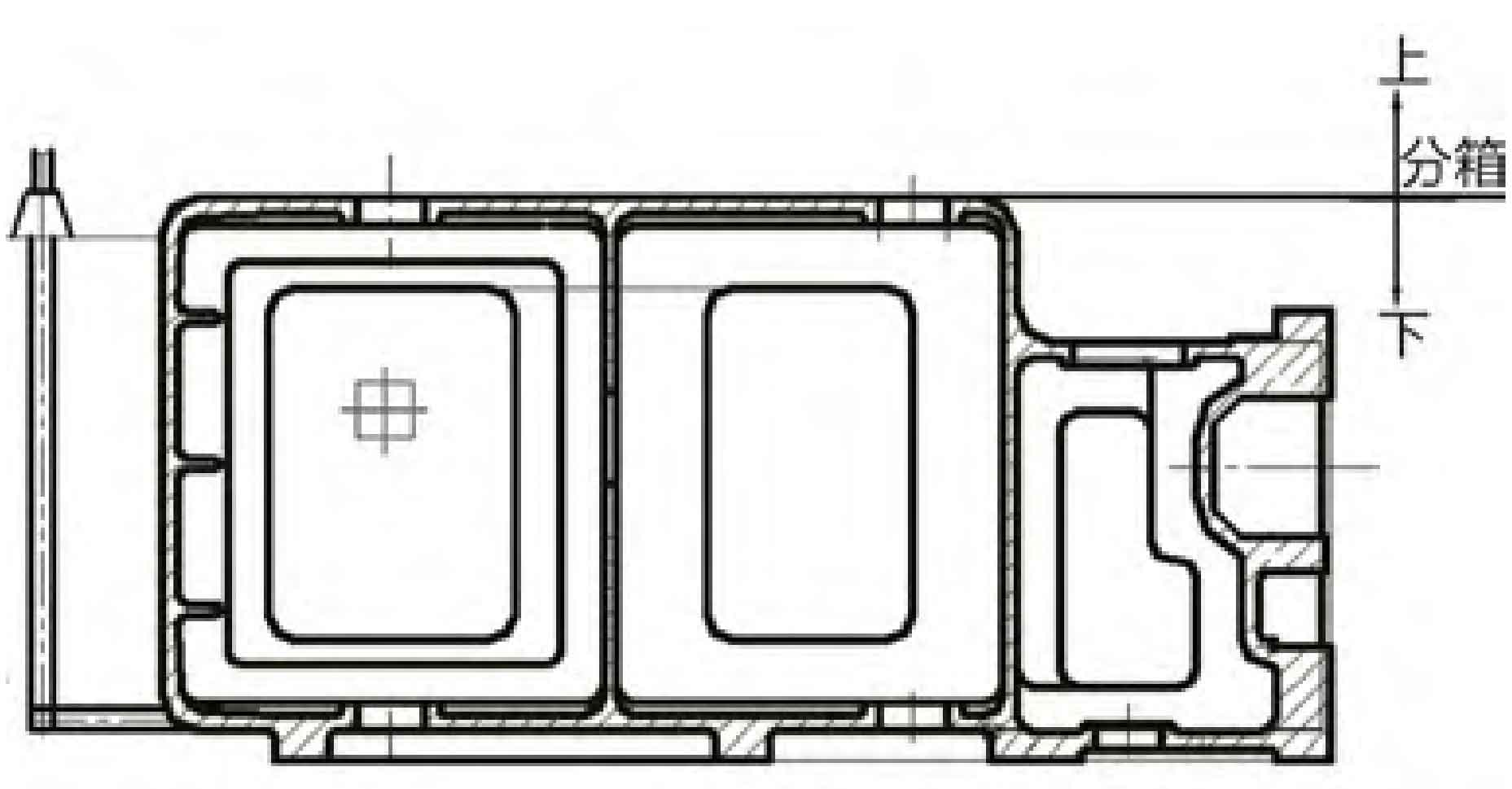

According to the selection principle of the parting surface and the structural characteristics, technical requirements and production conditions of the column, in order to ensure the quality of the column guide surface and achieve feeding, the parting surface and pouring position of the column are shown in the figure below.

4. Sand core design of sand castings

The sand core shall be designed to minimize the separation of sand core and the use of core support; It is necessary to facilitate the process from core making to core lowering and the air outlet of sand core; In addition, the sand core shall be accurately positioned and firmly fixed. The inner cavity of the column is complex in structure and large in size, with 37 sand cores. Since there is no air outlet at the upper part of the sand cores at both ends, the air is exhausted by connecting the air outlet at the side.

5. Design of gating system for sand castings

(1) Type of gating system

The column pouring system adopts the bottom pouring type, and the molten iron enters the mold cavity from the lower plane of the column, as shown in the figure.

The bottom pouring gating system is adopted, the liquid metal filling is relatively stable, the liquid level is gradually rising, avoiding impact, splash and oxidation, which is conducive to the floating of impurities in the molten iron and the discharge of gas in the mold cavity, thus effectively preventing the sand casting guide rail from slag, porosity and other defects.

(2) Gating system calculation

The specific pouring speed is used to calculate the size of the gating system. This method can be used to calculate the gating system of various alloys and sand castings, mainly for large and heavy sand castings.

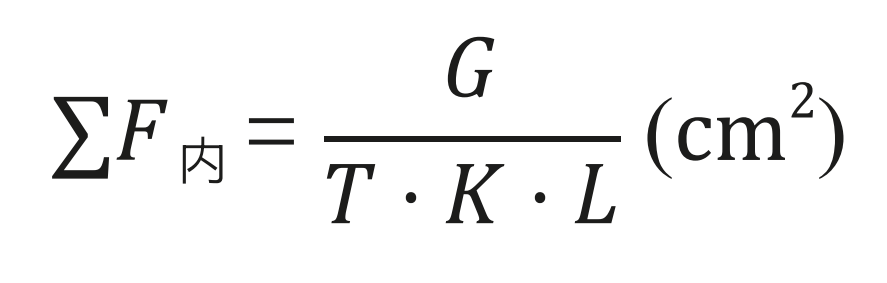

(a) Calculation formula of ingate area:

Where, G is the mass of liquid metal flowing through the choke section of F, kg; T is pouring time, s; K is the pouring speed per unit area, kg/(cm2 · s); L is the liquid metal flow coefficient. The liquid metal mass of sand casting is 52 000 kg, the pouring time is 206 s, the pouring speed is 0.9 kg/(cm2 · s), and the liquid metal flow coefficient is 1. According to the formula calculation, combined with the structural characteristics of sand castings and actual production experience, the mold shall be filled quickly during pouring, and the value of Σ S shall be equal to 281 cm2.

(b) The gating system is semi closed. The semi closed gating system has fast filling, good slag retaining effect and is not easy to be involved in gas. According to the formula of actual production experience, Σ S straight=1.2 × Σ S inner=337 cm2; Σ S horizontal=1.4 × Σ S=393 cm2.

6. Riser and chill setting

(1) Riser setting

The wall thickness of the column guide rail and the upper and lower end face screw package is large, which is easy to form shrinkage cavity and porosity. Risers are required for feeding. In order to ensure smooth feeding of the two guide rails, gangways are also used to connect the two guide rails. In order to prevent shrinkage cavity and porosity, 20 square exposed risers are set on the column.

(2) Chiller setting

In order to prevent shrinkage cavity and porosity, ensure the dense structure of the column guide rail and the feeding distance of the riser, an external cold iron is set at the thick parts of the guide rail for quenching, and 256 pieces of external cold iron are placed in the whole column.

7. Selection of other process parameters

(1) Shrinkage

According to actual production experience, the shrinkage of sand casting is 1%.

(2) Machining allowance

According to the size and structural characteristics of sand castings, the machining allowance of sand castings shall be selected according to GB/T 6414-2017.

(3) Unpacking time

According to the structural characteristics and environmental conditions of sand castings, the unpacking time is selected as 368 h after pouring, and the insulation time of columns is selected as 392 h.