Because the supercharger shell has complex structure, thin wall and multiple layers, small batch and multiple varieties, poor stability of casting surface quality and dimensional accuracy, and high rejection rate, it can not meet the user’s requirements for casting quality. In order to improve the casting quality and develop new casting technology, ZHY Casting began to study the application of 3DP technology in casting production in 2017.

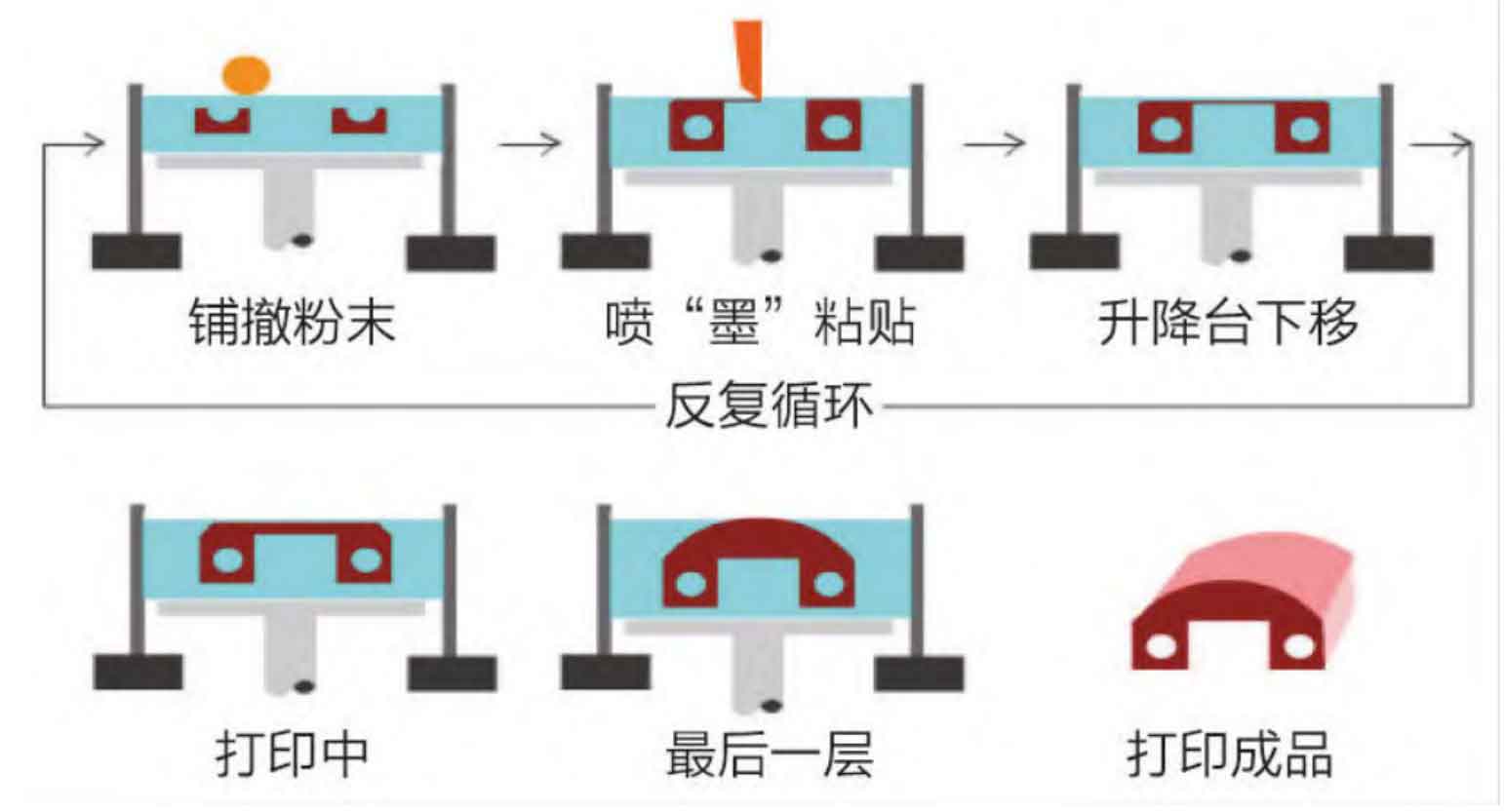

3DP (Three Dimensional Printing and Gluing) is a kind of 3D printing technology, also known as Binder Jetting and Inkjet Powder Printing. Like the SLS process, 3DP also makes parts by bonding the powder into a whole. The difference is that it is not bonded by laser melting, but by the adhesive sprayed by the nozzle. The working principle of using this technology to print sand mold is as follows: first, the sand spreader will sand the molding sand layer by layer according to the set quicksand volume and compact it, and then the printing nozzle will “print” the resin adhesive on each layer of sand. After “printing”, the lifting platform will drop 0.3~0.5 mm, the sand spreader will lay sand again, and the printing nozzle will “print” again, and so on, until the complete sand mold is printed, Finally, remove the excess powder material on the model, as shown in the figure. 3DP technology has fast forming speed, no supporting structure, and is convenient to remove excess powder. It is especially suitable for making complex inner cavity shapes. Consumables and forming materials are relatively cheap, and printing costs are low.

Since 2017, ZHY Casting has been engaged in the application research and development of 3DP technology. The application of 3DP technology in the development of new products has greatly shortened the development cycle of new products, and has successfully developed 75 types of qualified supercharger housings. In May 2020, 3DP technology was popularized in mass production products. Now 25 varieties of various axial flow supercharger shells have been developed, and 15 kinds of shells have been mass produced. The product qualification rate has increased by 15% compared with that of traditional casting, laying a solid foundation for the company to improve quality and efficiency.