CN7M investment casting material is austenitic stainless steel with good corrosion resistance, and its chemical composition is shown in the table. After solution treatment at 1 120~1 150 ℃, its internal structure is single-phase austenitic structure. In the production of investment casting, compared with the common 18-8 stainless steel, CN7M has poor thermal conductivity, serious component segregation and is prone to hot cracks. In this research and production process, the material used is purchased CN7M bar, and its main element composition is consistent with that of CN7M casting material.

| C | Si | Mn | P | S | Cr | Ni | Mo | Cu | Fe |

| ≤0.07 | ≤1.50 | ≤1.50 | ≤0.040 | ≤0.040 | 19.0~22.0 | 27.5~30.5 | 2.0~3.0 | 3.0~4.0 | Bal. |

The investment casting adopts water glass shell and medium-frequency furnace melting and pouring process, and the quality of investment casting varies from 5 to 50 kg. During the production of CN7M valve precision casting, our company produced a large number of crack defects that could not be repaired. All products, without exception, produced a large number of penetrating network cracks in the as-cast state, which could not be repaired and scrapped, and the company suffered great economic losses.

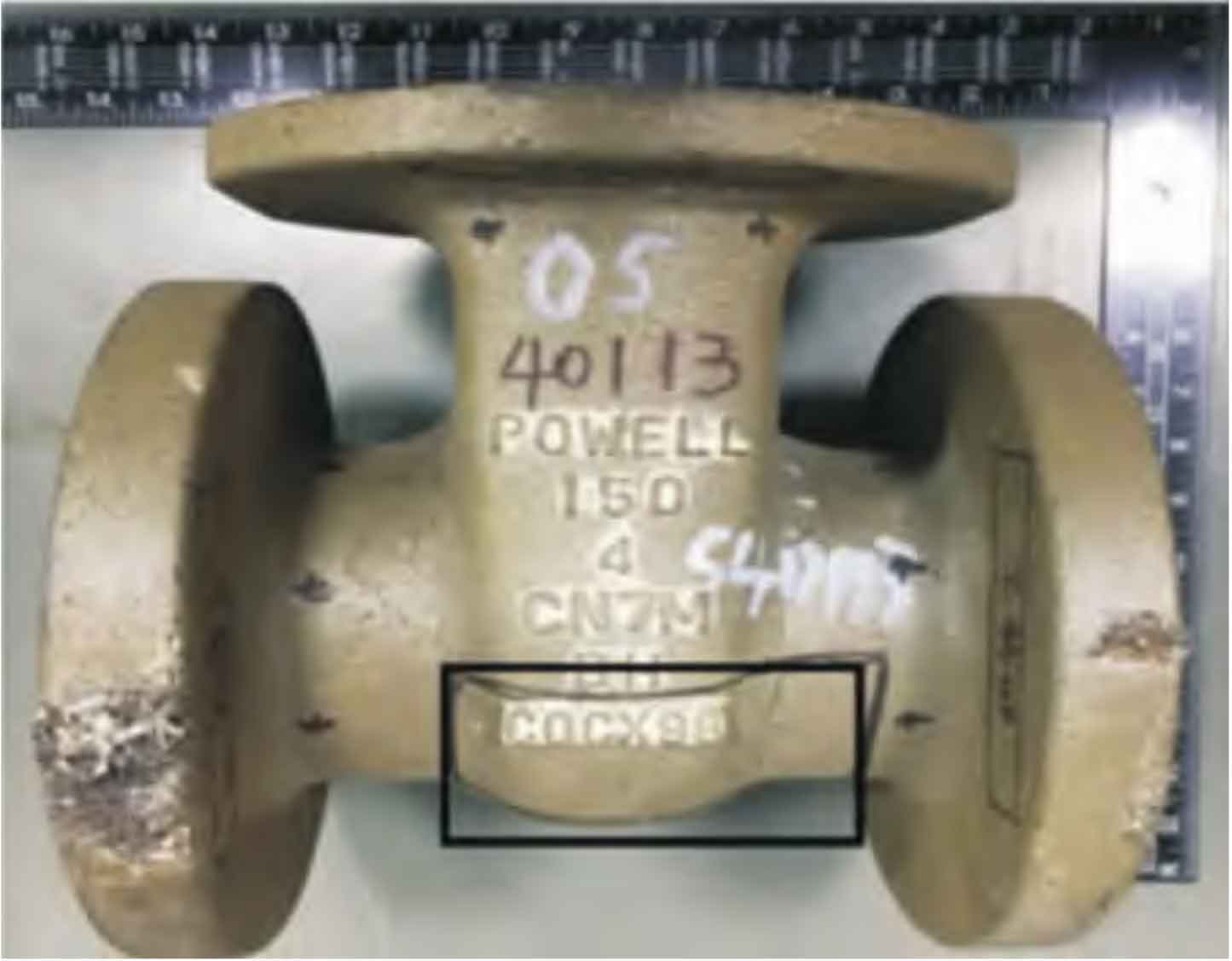

As shown in the figure, the surface of the cracked product is covered with network cracks, and the crack direction has no obvious preferred orientation. The cracks are mainly distributed in the variable section position except the flange plate. The maximum opening of the crack is about 0.6 mm, and there is no obvious plastic deformation on both sides. According to the crack morphology and crack condition, it can be judged that the crack is a typical investment casting crack.