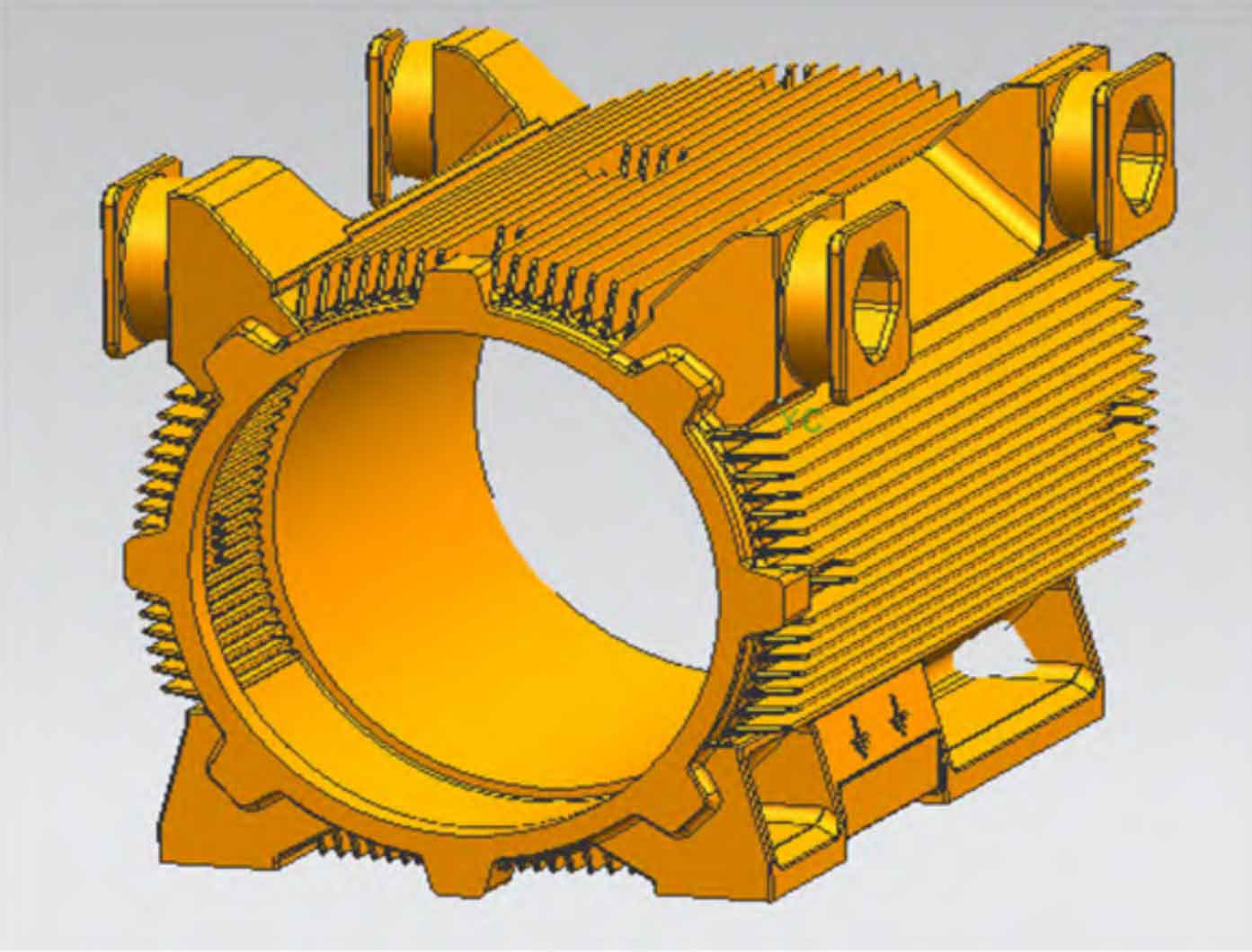

The production practice shows that after the motor shell casting is changed to the lost foam casting process, the yield of the casting is ≥ 97%, the metallographic structure and mechanical properties of the casting meet the standard, and the appearance quality of the lost foam casting is better than that of the lost foam casting produced by the original furan resin sand process (as shown in Figure 6). From the perspective of casting cost, the original furan resin sand process needs to add 1.1% resin and 0.5% curing agent, and the ratio of sand to iron is 5:1. For the lost foam casting process, the cost of raw materials for lost foam white mold per ton of lost foam casting is 33 yuan and the cost of coating is 30 yuan. According to the market price, compared with the furan resin sand process, the cost of raw materials can be saved by 600 yuan, and the labor efficiency of lost foam casting is twice higher than that of resin sand process. The labor cost per ton of lost foam casting can be saved by 800 yuan, and the comprehensive cost per ton of lost foam casting can be reduced by 1400 yuan. It can be seen that this type of motor shell is suitable for changing to the lost foam casting process.

The lost foam casting mould for medium and large motor shell is integrally formed, with different shrinkage rates for radial and height; The step-type gating system is adopted to strictly control the drying temperature and time of the white mold, and focus on the coating hanging property, normal temperature/high temperature crack resistance, shelling property and other properties; With the pouring temperature of 1490~1500 ℃ and the pouring vacuum controlled at -0.065~-0.07 MPa, the lost foam casting with good surface quality, qualified size and satisfactory performance can be produced, and the production cost per ton of lost foam casting is 1400 yuan lower than that of furan resin sand process. The practice has proved that it is feasible to produce motor shell castings by lost foam casting process.