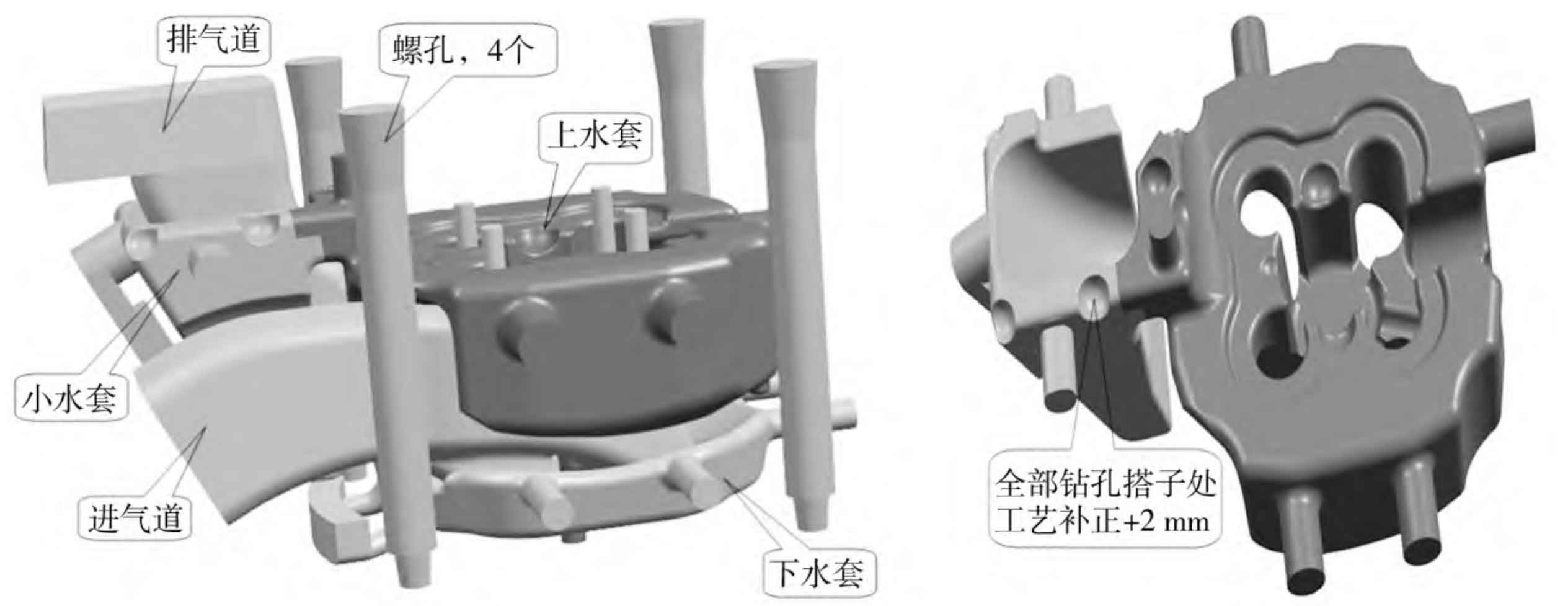

1. Design of cold core box of diesel engine cylinder head

All the molds of the cold core box of the diesel engine cylinder head are designed in 3D, programmed by computer, and processed by the machining center network. The working surface, parting surface and the matching surface of the movable block of the mold are all processed by numerical control, and the surface roughness reaches Ra3.2 μ m. The flatness of die parting surface is less than 0.12 mm.

The dimensional deviation of the working surface of the core box shall be manufactured according to the accuracy of IT11 in GB/T1800.3-1998 Tolerances and Fits. The size deviation is generally negative, the convex part is positive, the center distance of the convex is ≤ 500 mm, and the size deviation is ± 0.15 mm; Center distance > 500 mm, dimension deviation is ± 0.20 mm. The core box is made of aluminum ZL107, with hardness of about HB70, tensile strength > 160 MPa, and the frame is made of HT250 [2], with good strength and long service life.

All sand cores are made by core shooting machine, and the mold surface roughness is Ra1.6 μ m. The body dimension accuracy is ± 0.1 mm, and the unevenness of the core box reference plane is ≤ 0.1 mm within the range of 1000 mm. See Fig. 1 for 3D sand core of diesel engine cylinder head.

2. Core making process

The overall requirements for the control of the core making process of the cold box include the preparation of raw materials (raw sand, resin, triethylamine), the preparation of the mixture, the core making, coating, storage, core setting, pouring and other whole process. Take the control of water hazard as the main consideration, and comprehensively control equipment, raw materials, temperature, pressure, time and other factors. See the process flow of cold core box core-making for details.

2.1 Equipment used

The equipment model is 25L and 40L cold core box core shooter. Before the core making operation, check whether the core box is clean, whether the release agent is sprayed, whether the compressed air is dry, whether the sand shooting plate, the upper top core plate (ammonia blowing plate) and the upper and lower core boxes are sealed, whether the sealing ring is aging, whether the sand shooting nozzle sealing ring is damaged, and whether the tail gas treatment system is normal.

2.2 Selection of core making parameters

Core shooting pressure: 0.35~0.5 MPa; Ammonia blowing and purification pressure:

0.2~0.3 MPa; Ammonia blowing time: 2~10 s; Purification time: 10~60 s.

2.3 Sand mixing

The purpose of sand mixing is to make the original sand evenly coated with resin and activator for hardening. Mix the raw sand+component I+component II+additive, the component I and component II composition ratio is 1:1, and the addition amount is 1.0%~1.1% of the weight of the raw sand. Add the appropriate additive (select powder or granular according to the specific requirements, and the addition amount is 3%~7% of the weight of the raw sand) to the raw sand for sand mixing, and sand is produced in 30~60 seconds.

2.4 Sand shooting

The resin sand is blown into the core box, and the core shooting pressure is 0.35~0.5 MPa. For sand cores that are difficult to fill tightly, the injection pressure can be appropriately increased. For sand cores that are easy to fill, reducing the injection pressure will reduce the damage degree of the mold and prolong the service time of the mold. The sand shooting time and exhaust time can be extended from the conventional 3-5 s to 3-5 s to obtain a core with good surface.

2.5 Amine blowing curing

After mixing triethylamine atomization with compressed air, blow gaseous amine for curing (curing core), and blow ammonia and purification pressure: 0.2~0.3 MPa; Ammonia blowing time is 2~10 s.

2.6 Purge

Blow compressed air (solidify and remove ammonia odor) and wash to purify the residual gas. Purification time: 10~60 s.

2.7 Mold opening and coring

3. Paint

Alcohol-based coating shall be used, and the coating shall be applied 30 minutes after the sand core is hardened and ignited immediately.

4. Storage of cold core

Under dry conditions, the strength of the prepared cold core will gradually increase within a certain period of time, and will gradually decrease after a small increase in strength under high humidity conditions. Therefore, the cold core sand core should be stored for a long time as far as possible, especially in the high temperature and high humidity season, which should not exceed 24 hours, in order to avoid the strength loss caused by the reaction with water, or the air hole casting defect caused by the increase of sand core moisture.

5. Drying

The core needs to be dried before use to remove residual moisture. The core drying temperature (insulation temperature): 180~220 ℃, drying time: 40 min (surface drying furnace); 2-3 h (kiln drying).

6. Hot air for mold blowing

After the core of the cold core box falls into the mold, the temperature difference between the mold and the core will cause water migration, which will cause water condensation on the core surface and damage the resin bonding bridge. Therefore, hot air shall be blown to dry the mold after the box is prepared. The insulation temperature is 60~80 ℃, and the insulation time is 2~3 h. Take the upper limit in winter and the lower limit in summer, and stop blowing before pouring.

7. Melting and pouring

(1) Smelting equipment: use 3 t medium-frequency induction furnace to melt alloy; The raw materials are special grade pig iron, high-quality scrap steel and recycled materials.

(2) The control range of chemical composition of molten iron is 3.65%~3.85% C, 1.5%~1.8% Si, 0.15%~0.30% Mn, ≤ 0.03% S, ≤ 0.05% P.

(3) Spheroidizing inoculation treatment: the addition amount of spheroidizing agent is 1.2%. The amount of inoculant added is 0.7%, of which 0.3% is covered in the ladle, 0.3% is added to the ladle along with the flow in the tapping bath at the time of tapping, and 0.1% is added to the instantaneous inoculant during pouring. Silicon barium inoculant YFY-150 (as shown in the table) is used for covering, flowing and instantaneous inoculants.

| Si | Ba | Ca | Al | Fe |

| 70~75 | 2.0~3.0 | 1.0~2.0 | ≤1.5 | Allowance |

(4) The temperature of molten iron entering the mold cavity shall be controlled from 1360 ℃ to 1390 ℃. Gun-type thermometer is used for multiple measurements to ensure that the molten iron injection temperature meets the process requirements.

8. Packing

After pouring for 12 hours, the box shall be opened.

9. Heat treatment

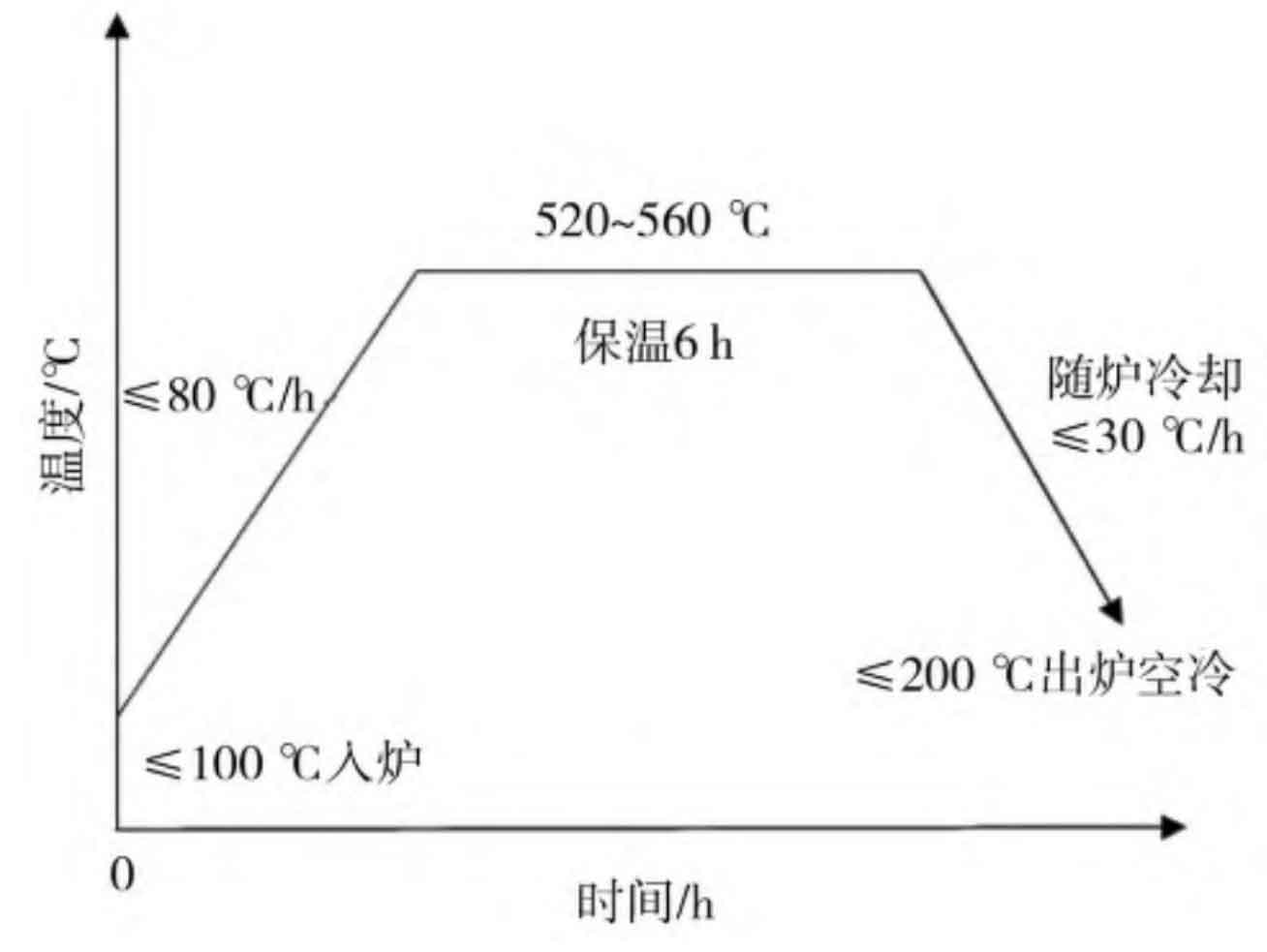

The cold core box castings also need to undergo stress relief annealing heat treatment, and the specific process is shown in Figure 2.

10. Inspection

After the cold core box casting is poured, the physical and chemical inspection, mechanical properties and metallographic structure inspection of the attached cast sample are qualified. At the same time, according to the requirements of the technical documents, dye penetrant inspection, ultrasonic inspection and hydraulic test were carried out on the diesel engine cylinder head, and the test results met the technical requirements.