1. Chemical composition detection

The ARL3460 direct-reading spectrometer is used for chemical composition detection. The results of chemical composition detection are shown in Table 1.

| Value | Wire feeding length/m | Wire feeding speed/m · min^-1 | Temperature before wire feeding/℃ | Reaction time/s | Pouring temperature/℃ |

| Project | 14.5±0.15 | 18±0.2 | 1 430~1 450 | 40~60 | 1 400~1 360 |

2. Metallographic structure test

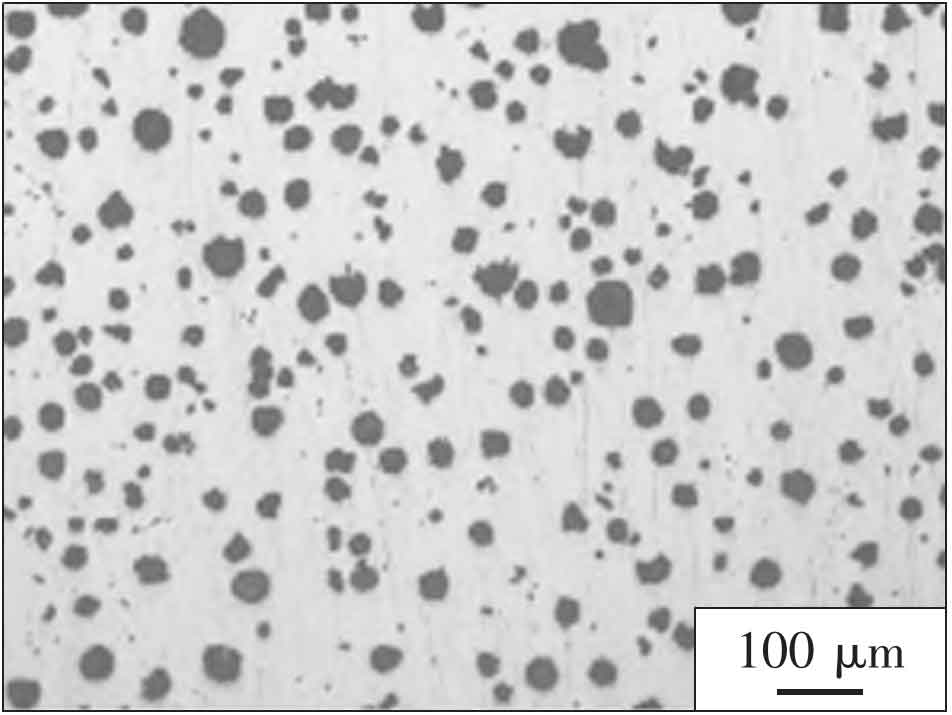

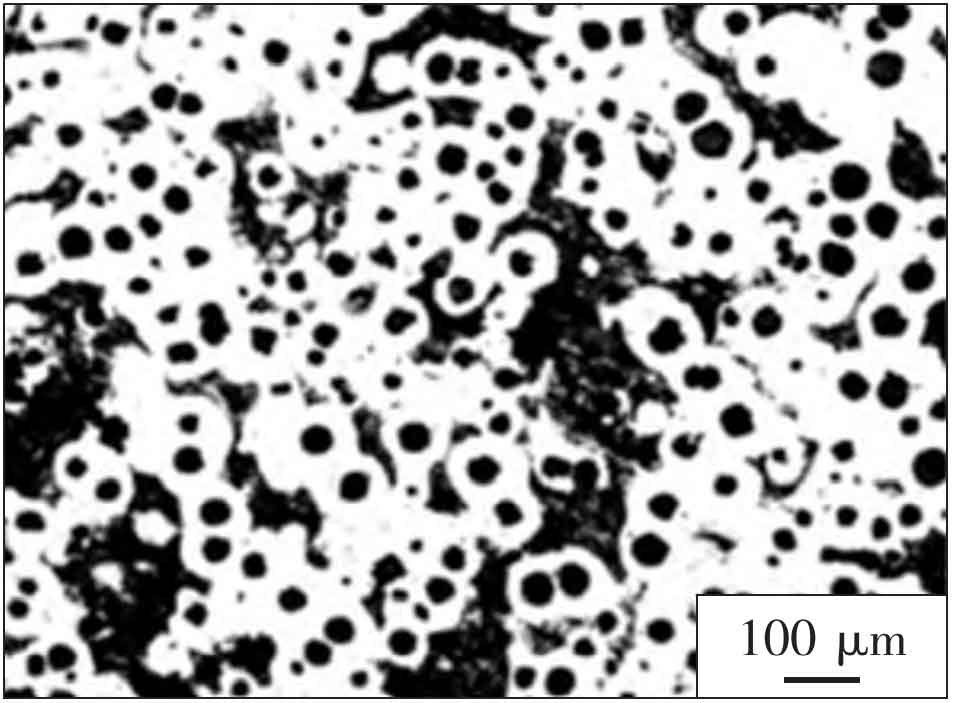

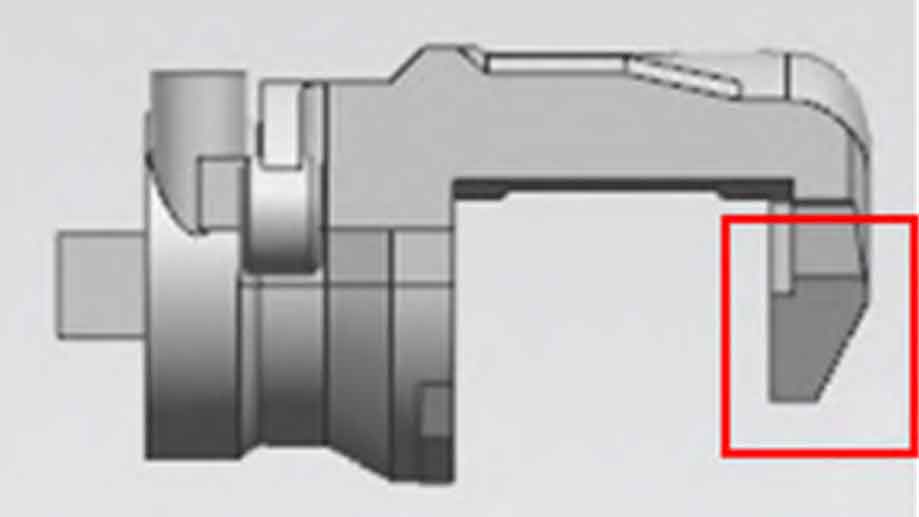

The preparation and testing of bulk metallographic samples were carried out according to GB/T 9441-2009 Metallographic Examination of Ductile Cast Iron. The wall thickness of the tested part of bulk metallographic structure is 20 mm, the tested part is shown in Figure 1, and the metallographic structure test results are shown in Figure 2. It can be seen that the spheroidization rate is more than 90%, and the matrix structure is 75% ferrite+25% pearlite, without cementite.

3. Mechanical property test

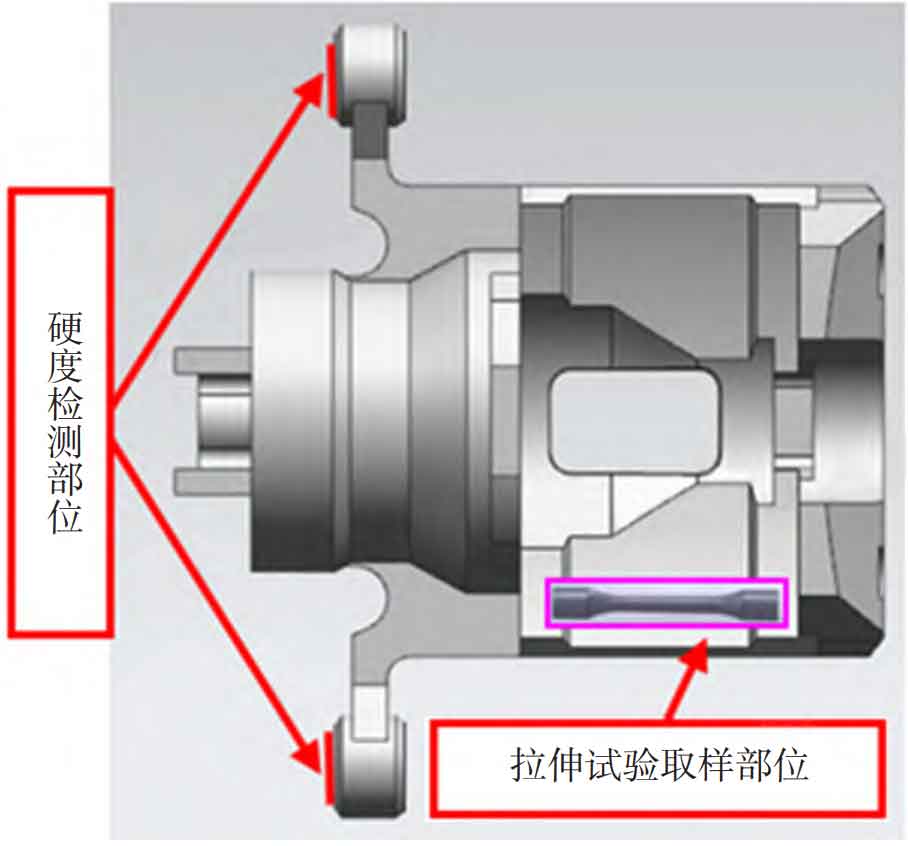

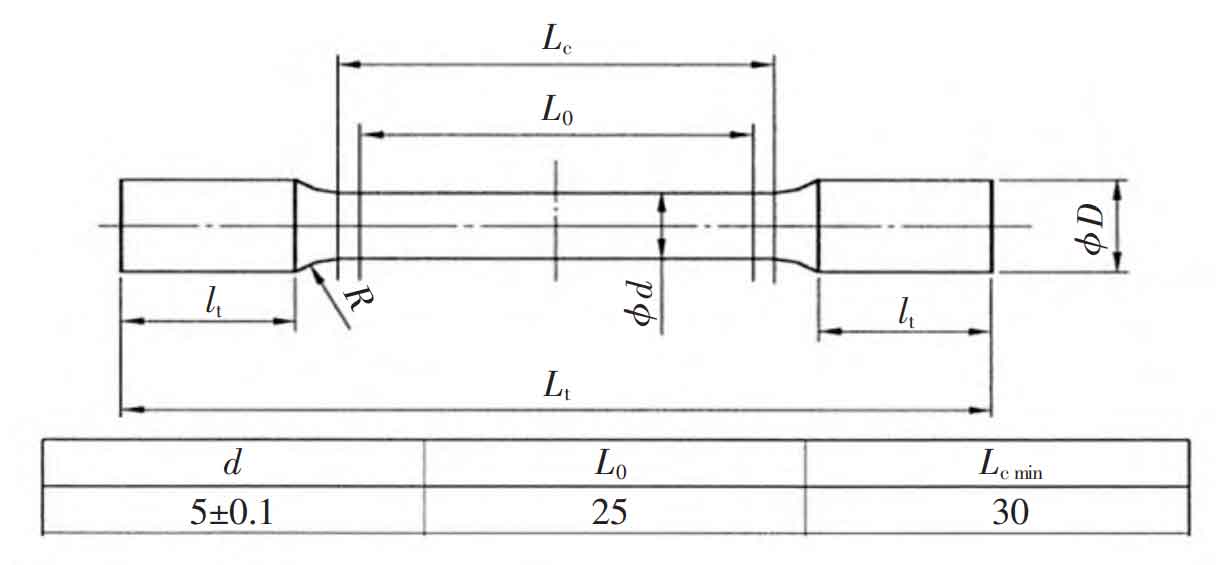

Figure 3 shows the location of mechanical property testing, and the machining size of the body test bar is shown in Figure 4. The electronic universal testing machine and Brinell hardness tester are used to test the mechanical properties and hardness respectively, and the test results are shown in Table 2.

| Serial number | C | Si | Mn | Cu | P | S | Mgremnant |

| 1 | 3.78 | 2.76 | 0.30 | 0.17 | 0.028 | 0.011 | 0.044 |

| 2 | 3.74 | 2.74 | 0.29 | 0.15 | 0.033 | 0.010 | 0.040 |

| 3 | 3.79 | 2.81 | 0.28 | 0.16 | 0.028 | 0.010 | 0.043 |

| 4 | 3.80 | 2.79 | 0.30 | 0.16 | 0.030 | 0.010 | 0.050 |

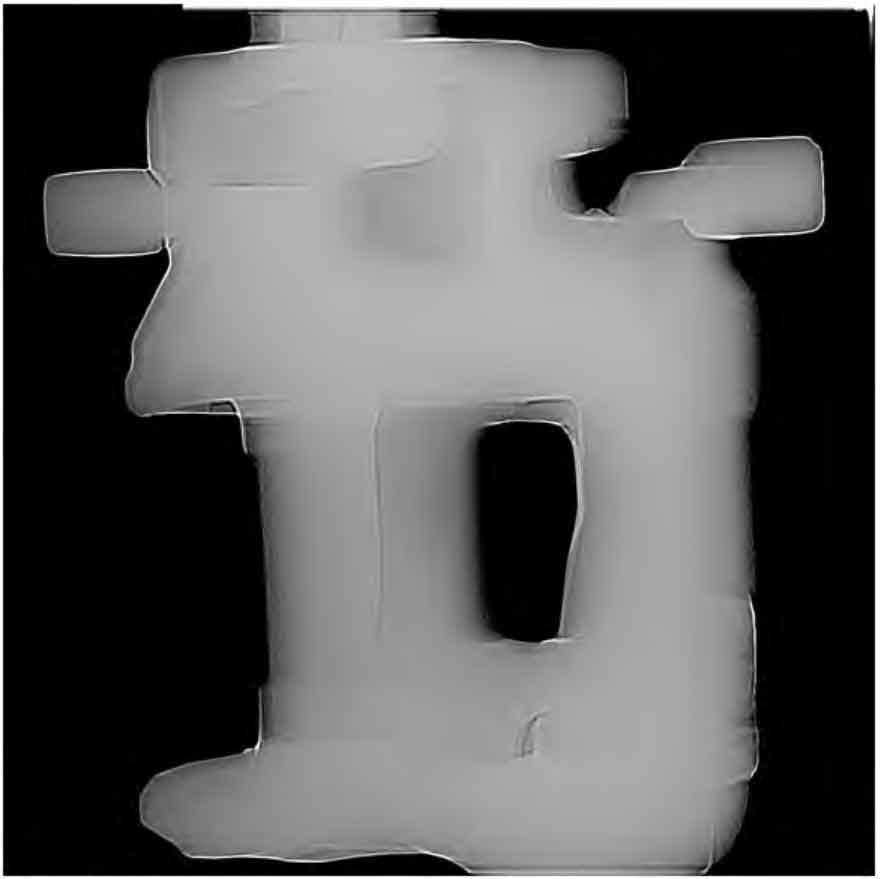

4. Internal quality inspection

The internal quality of ductile iron castings was tested by X-ray flaw detection and sectioning dye flaw detection. The test results are shown in Fig. 5 and Fig. 6. According to the flaw detection results and staining results, no shrinkage defects were found inside the ductile iron castings.

After preliminary development and optimization, the utilization rate of molten iron in this process layout is 61.6%, which is 19% higher than that in the conventional layout. The mechanical properties, internal quality and appearance quality of ductile iron castings meet the requirements. Now the ductile iron castings have entered the stage of mass production and the production process is stable. The scrap rates of # 1~# 6 ductile iron castings are 2.0%, 2.1%, 2.3%, 1.6%, 1.5% and 1.9% respectively, and the overall scrap rate is 1.9%.