In principle, for ductile iron castings that can realize self-feeding as a whole, there is no need to set another riser for feeding. However, in view of the complexity of the product structure, for the partial thickening caused by the core gap and the small amount of sand core floating up, it is necessary to supply a certain amount of safety protection molten iron at the initial solidification stage of liquid iron shrinkage to prevent the shrinkage porosity and shrinkage defects of ductile iron castings.

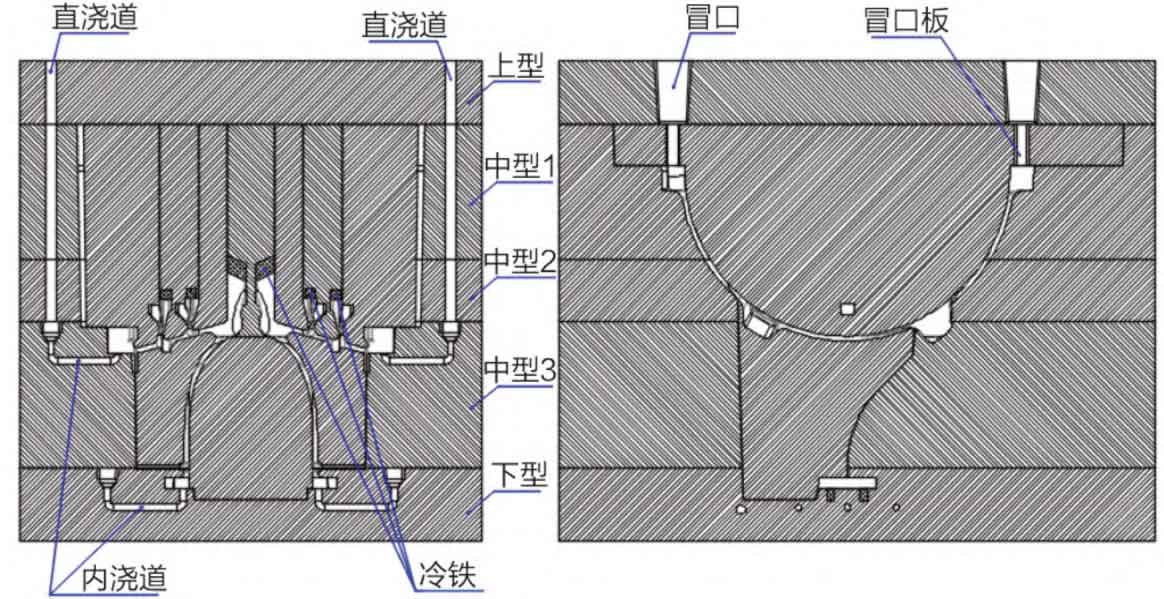

Therefore, 6~8 risers (see figure) are set above the mold to store about 2.5% of molten iron by pouring weight, and are connected with the mold through the flaky riser neck. This can not only provide a certain amount of safe molten iron at the initial stage of solidification, but also timely close the connection between the mold and the external atmosphere before graphitization expansion, and build a closed self-feeding area to obtain dense ductile iron castings. At the same time, the riser above the mold can play a good role in venting during the pouring and filling process.