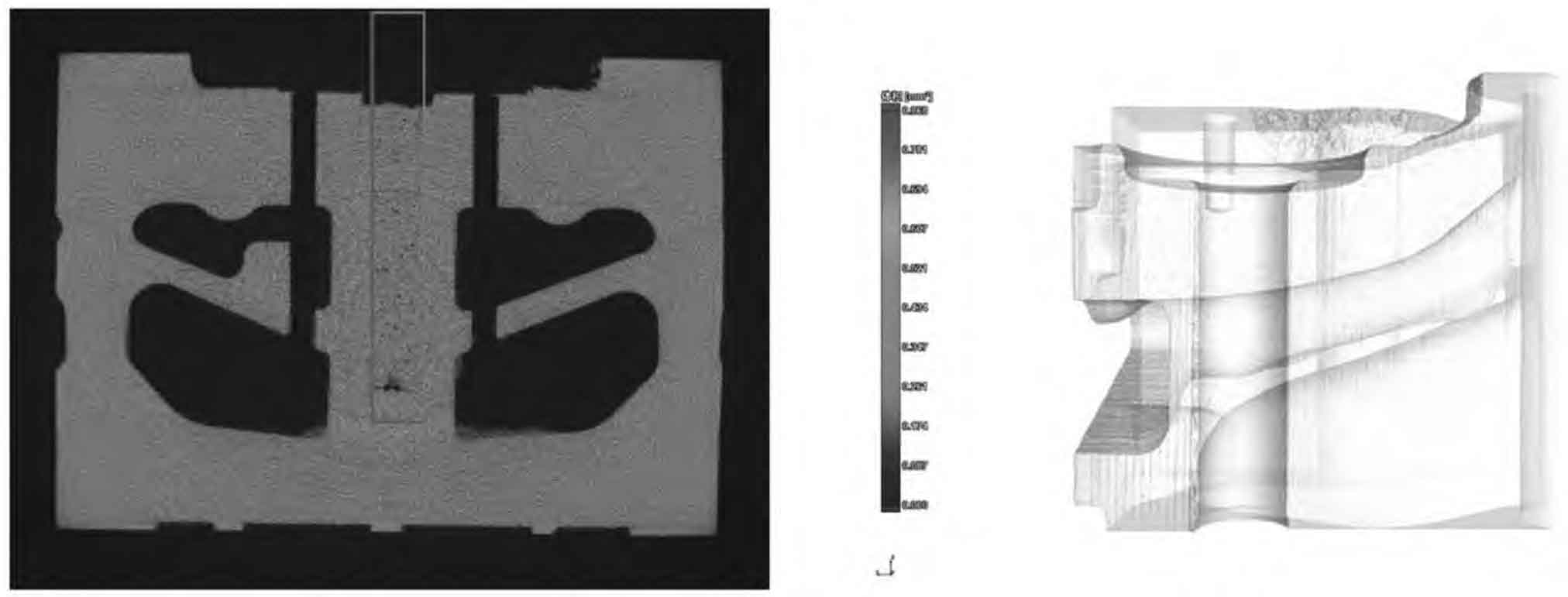

The mechanical properties and metallographic structure of the cylinder head casting body meet the technical requirements. At the same time, the physical and chemical testing center of metal materials was entrusted to use nanoVoxel 4000 for X-ray micro-CT testing. No casting defects such as air holes and shrinkage porosity were found in the injector hole. The frame selection part was caused by the removal of aluminum core, not the internal defects of the cylinder head casting.

(1) The traditional low pressure casting can only feed through the inner gate, and the self-feeding non-pressure low pressure casting can control the smooth filling of mold through the inner gate, and at the same time, the thick part of the casting can be fed through the top riser to avoid defects.

(2) The 3D printing core manufacturing technology can effectively reduce the gas generation of sand core, and avoid the problems such as difficult manufacturing of complex shape manual core and poor dimensional accuracy.

(3) According to the improved process plan, the casting qualification rate was greatly improved, and the mechanical properties of the cylinder head castings met the specified technical requirements.