At present, the company’s existing customers adopt the horizontal split KW static pressure molding line, air pre-compaction and high pressure multi-contact compaction molding production, and the maximum compaction specific pressure is 1.25 MPa. The size of sand box is 1100 mm × 900 mm × 350/250 mm, the production efficiency is 90 type/h.

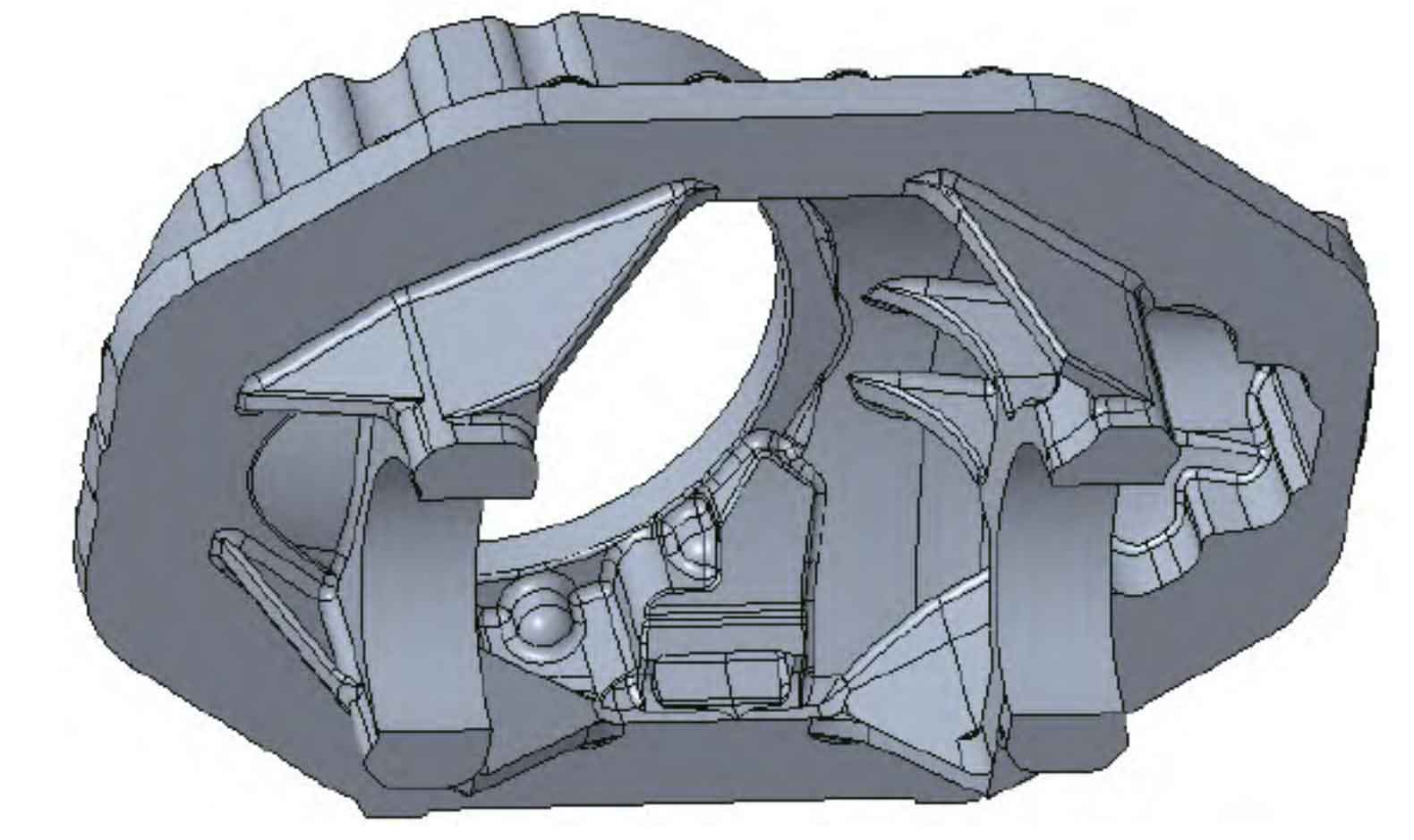

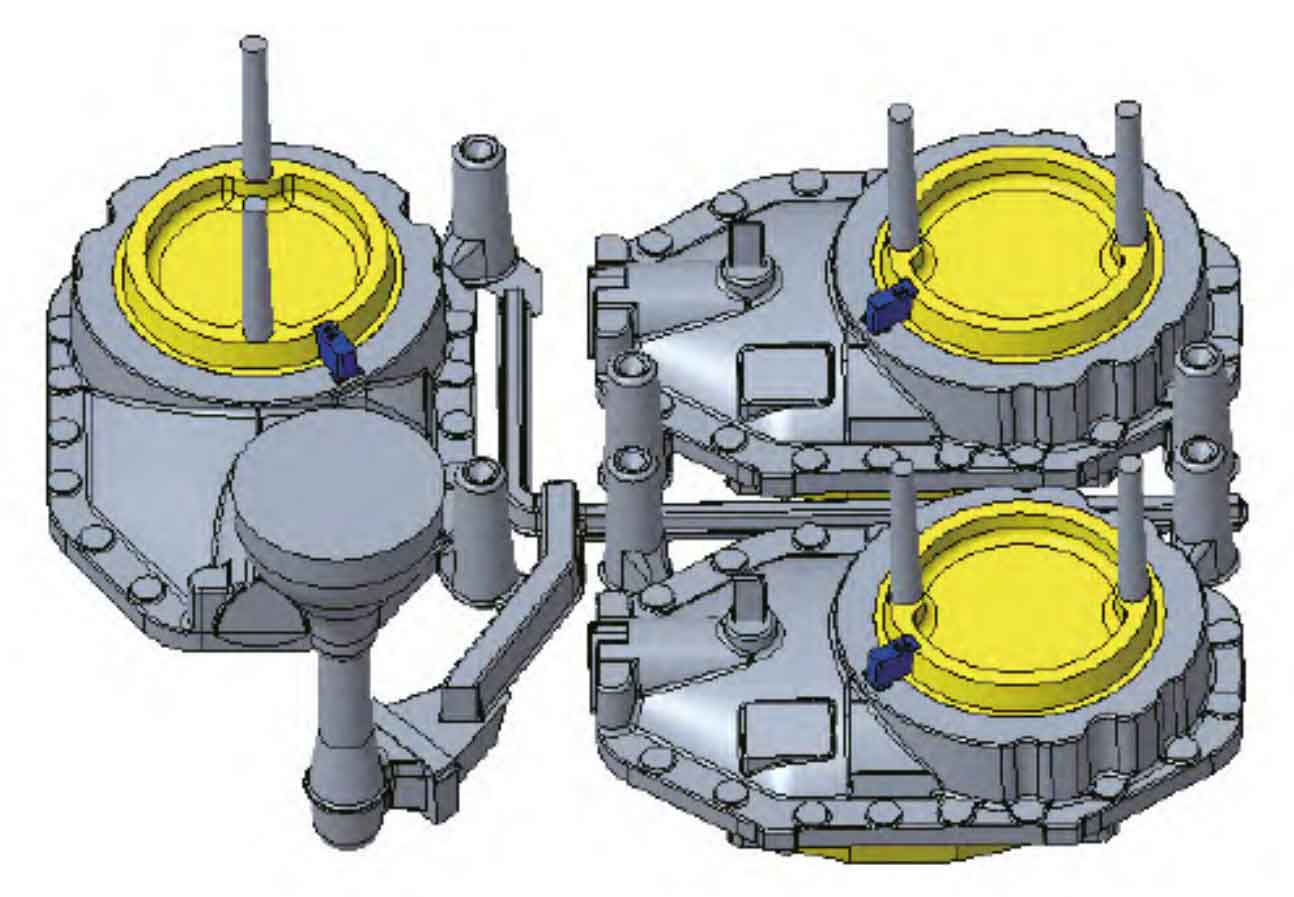

The main reducer shell is made of QT450-10, the unit weight of the product is 37.5 kg, and the maximum outer contour dimension is 548 mm × 360 mm × 180 mm, the main wall thickness is 12 mm, there are many thick hot spots, some of which are far away from the flange, and the product structure is shown in Figure 1. In the layout process of the molding plate, a three-part, medium-injection gating system is adopted. On the premise of ensuring the product quality, the sprue design is located near the corner, so as to maximize the use of the molding plate space and improve the production efficiency and process yield. The casting process plan is shown in Figure 2.

The pouring position of the product is placed with the flange face downward. Each product uses two internal runners, an open pouring system, a riser is set at the hot spot for feeding, an air outlet needle is set at the upper mold, a cold rib is set at the boss, the sand core uses the hot core process, and the pouring temperature of molten iron is 1 380~1 420 ℃. The carbon and sulfur analyzer and direct reading spectrometer are used to detect the chemical composition of molten iron in front of the furnace, as shown in the table.

| Casting grade | C | Si | Mn | P | S |

| QT450-10 | 3.65~3.95 | 2.55~2.85 | 0.1~0.4 | ≤ 0.06 | ≤ 0.02 |

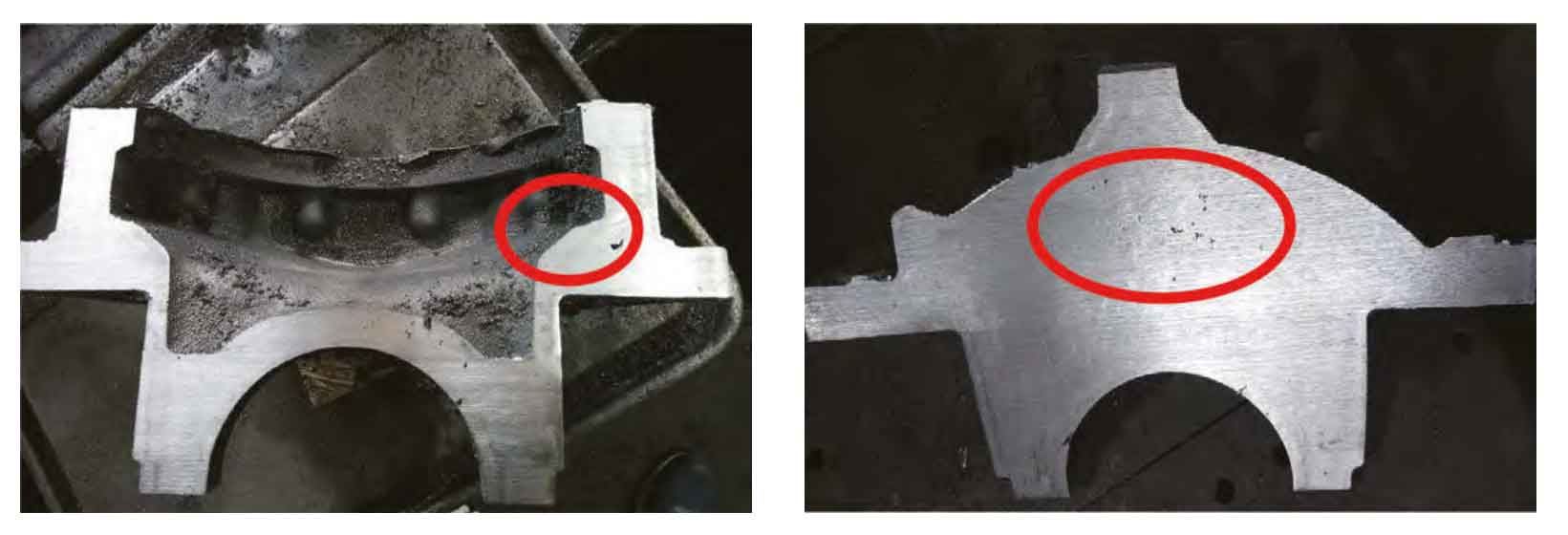

Through dissection and analysis, it is found that the main areas of shrinkage and shrinkage casting defects are the junction of the vertical and horizontal planes at the mounting surface of the bearing seat near the runner, and the interior of the shift fork hole boss. The casting defects are as shown in Figure 3. Therefore, in the new process design, these two positions should be taken as the key points of casting process design optimization.