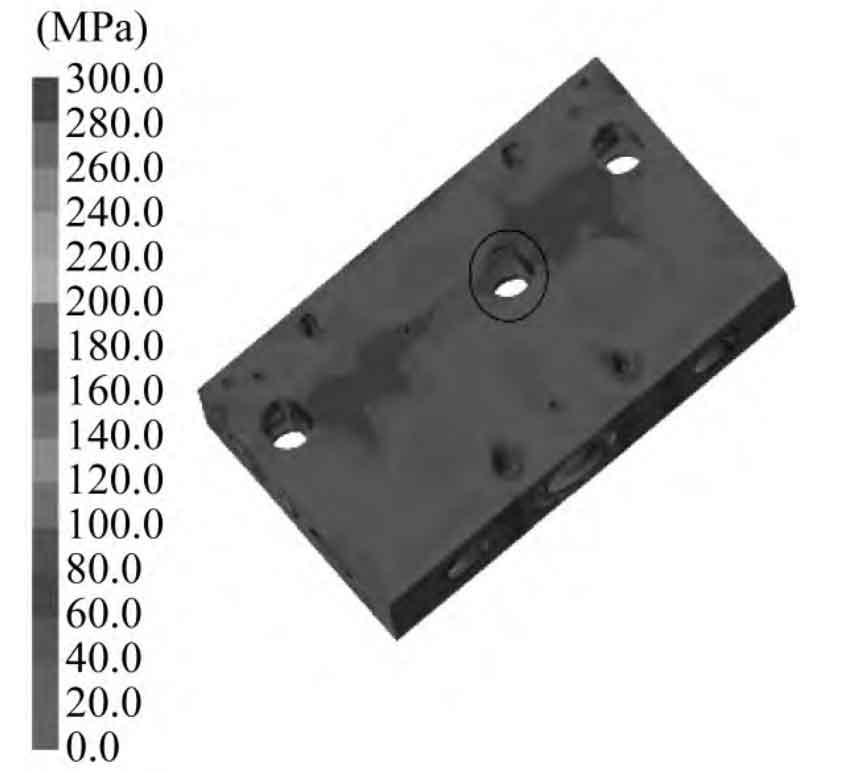

When the stress or deformation in the lost foam casting exceeds the strength limit or strain capacity of the alloy in this state, the lost foam casting will produce hot cracks. In order to verify the prediction results of hot cracks, the stress in this part shall be analyzed. The stress of lost foam casting is shown in Figure 1. At the round hole, that is, the hot spot of the lost foam casting near the riser, the heat dissipation of this part is slow, and the riser part finally solidified. The large temperature difference causes the stress level here to be higher than that of other parts of the lost foam casting, which causes stress concentration near the joint of the lost foam casting and the riser, and after reaching a certain limit, it will promote the generation of hot cracks.

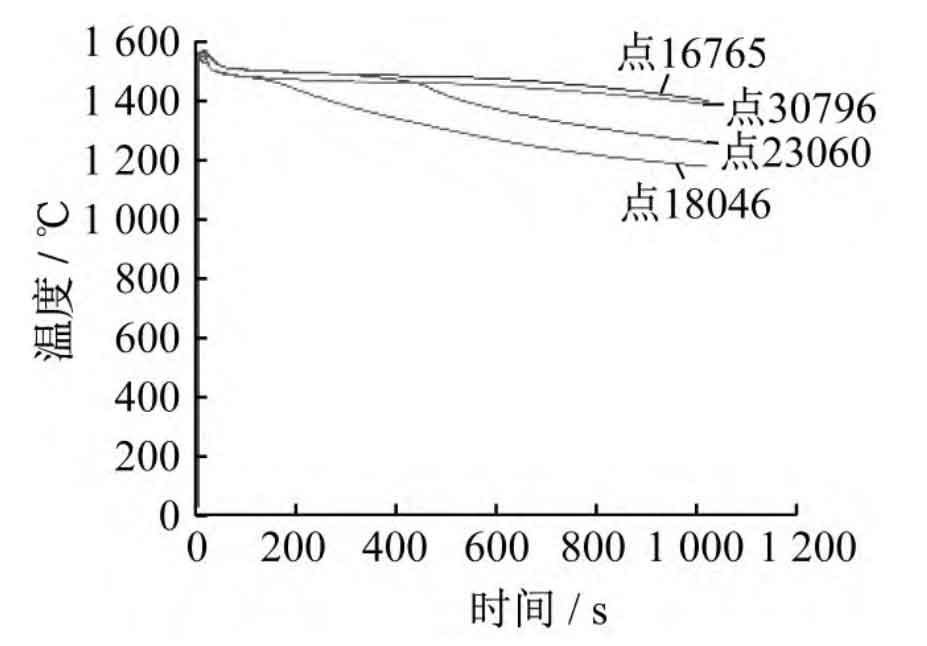

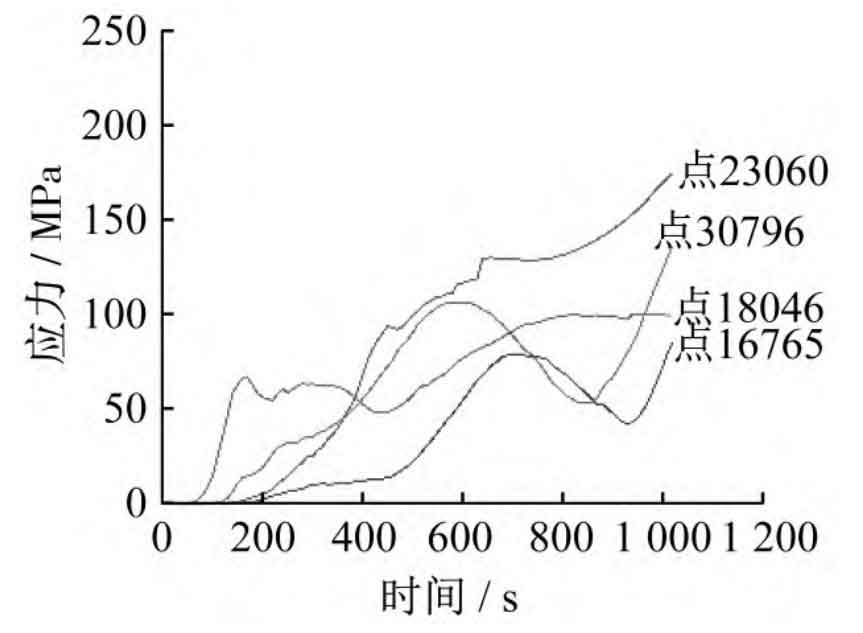

After the Box-Behnken experimental design optimization, the temperature change curve of the selected node position is shown in Figure 2, and the stress change curve is shown in Figure 3. It can be seen that the change potential of the stress curve at the selected point is relatively close. At the initial stage, the stress increases significantly with time, and the stress value decreases after the phase change caused by the temperature drop, which is due to the volume expansion caused by the phase change. With the cooling time, the stress value increases due to the austenite phase change. Since the maximum stress is far less than the strength limit of the lost foam casting at this temperature, it is not enough to cause hot cracking.

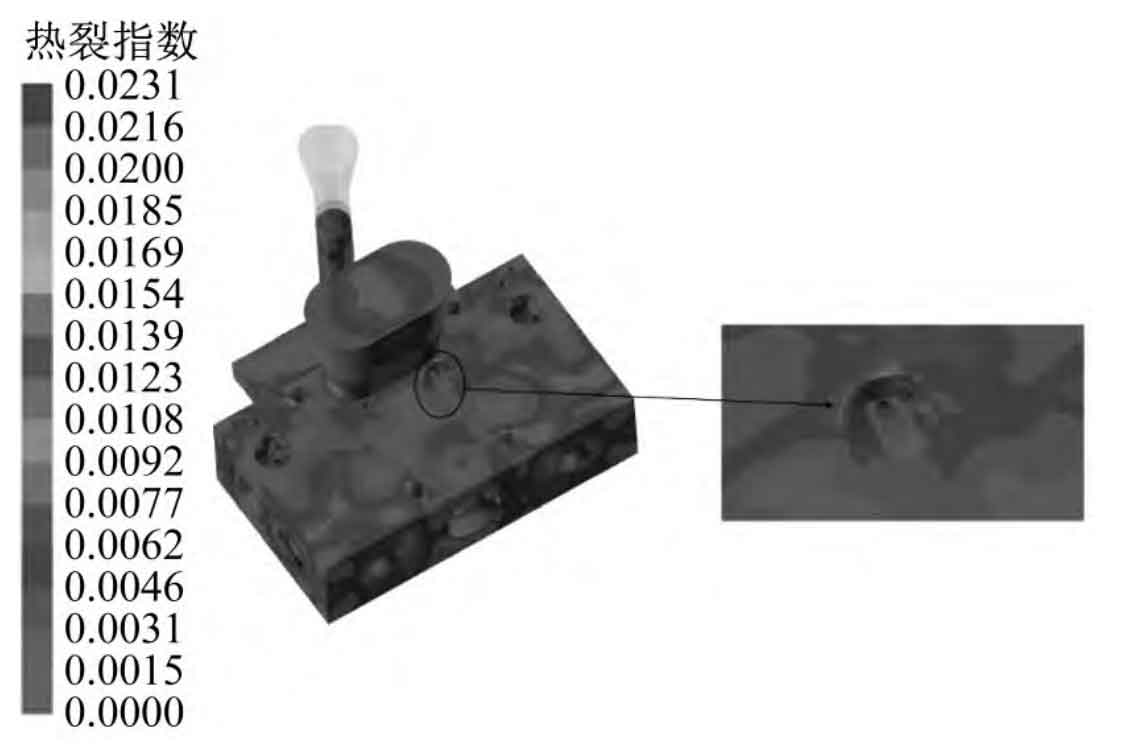

The prediction results of hot cracking of lost foam castings with response surface optimization scheme are shown in Figure 4. The original image is color, and different colors in the image represent the probability of thermal cracking. The color changes from purple to red, indicating that the hot cracking tendency of this part increases. When the color is close to yellow or red, thermal cracking may occur. The color of the original drawing is basically purple or blue, indicating that the tendency of thermal cracking is small. It shows that the hot cracking tendency is improved by using Box-Behnken test design.