1. Chemical composition

The ability of liquid metal to fill the mold cavity and obtain spheroidal graphite cast iron with complete shape and clear outline is called the filling ability of liquid metal. As the main wall thickness of the optimized box becomes thinner, under the same casting conditions, it is necessary to improve the filling capacity of liquid metal, that is, improve the fluidity of liquid metal.

| C+Si mass fraction/% | Modeling materials | Pouring temperature/℃ | Helix length/mm |

| 6.2 | Furan resin sand | 1 300 | 1 800 |

| 5.9 | Furan resin sand | 1 300 | 1 300 |

| 5.2 | Furan resin sand | 1 300 | 1 000 |

| 4.2 | Furan resin sand | 1 300 | 600 |

According to the fluidity law of ductile iron castings, under the premise of ensuring the material properties, the increase of carbon and silicon content can make the metal have good fluidity and strong filling capacity. For the fluidity test of ductile iron castings, spiral sample is adopted, and the groove section is 8mm × 8mm, the test results are shown in Table. According to the fluidity law of ductile iron castings and combined with the long-term experience in the production of metro gear boxes, the mass fraction of the chemical composition of the box material after lightweight is determined as C, 3.5%~3.8%; Si,2. 5% ~ 2. 8% ; Mn is less than 0.5%.

2. Casting conditions

The outer mold of the box is made of furan resin sand. Preheating the mold can reduce the temperature difference between metal and mold, thus improving its filling capacity. In winter casting production, when the temperature is around 0 ℃, the workshop temperature is less than 20 ℃. Before casting ductile iron castings, the industrial heater is used to bake the mold for 2h, and the air inlet temperature of 120 ℃ is set. The temperature in the mold can reach about 80 ℃, thus improving the filling capacity of molten metal and reducing casting defects such as insufficient pouring. In order to improve the quality stability in casting production and avoid the influence of ambient temperature on mold temperature, it is suggested to preheat the mold when producing thin-walled ductile iron castings.

3. Casting process

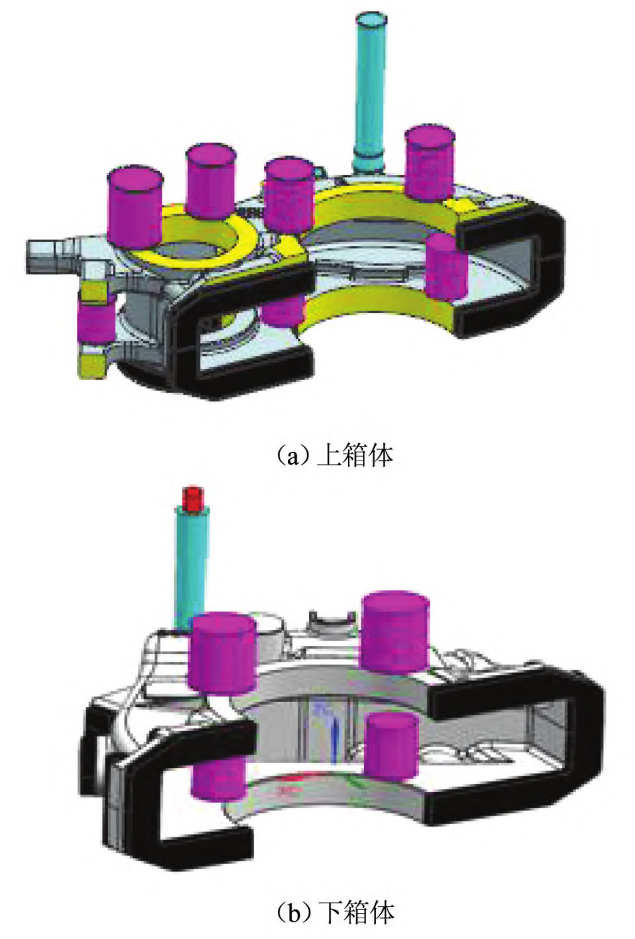

When designing the gating system, the structure should be as simple as possible. The more complex the gating system structure is, the greater the flow resistance of liquid metal is, and the lower the filling capacity is under the same hydrostatic head of liquid metal. During the process design, the pressure head height should be appropriately increased, the pressure of liquid metal in the flow direction should be increased, and the filling capacity should be improved. However, when the filling head is too high, not only spray and splash will occur, but also secondary oxidation of liquid metal and “iron bean” defects will easily occur. When the filling is too fast, the cavity gas will not be discharged in time, which is easy to cause casting defects such as “unable to pour” or cold shut. The casting process design of ductile iron castings is shown in Figure 1.

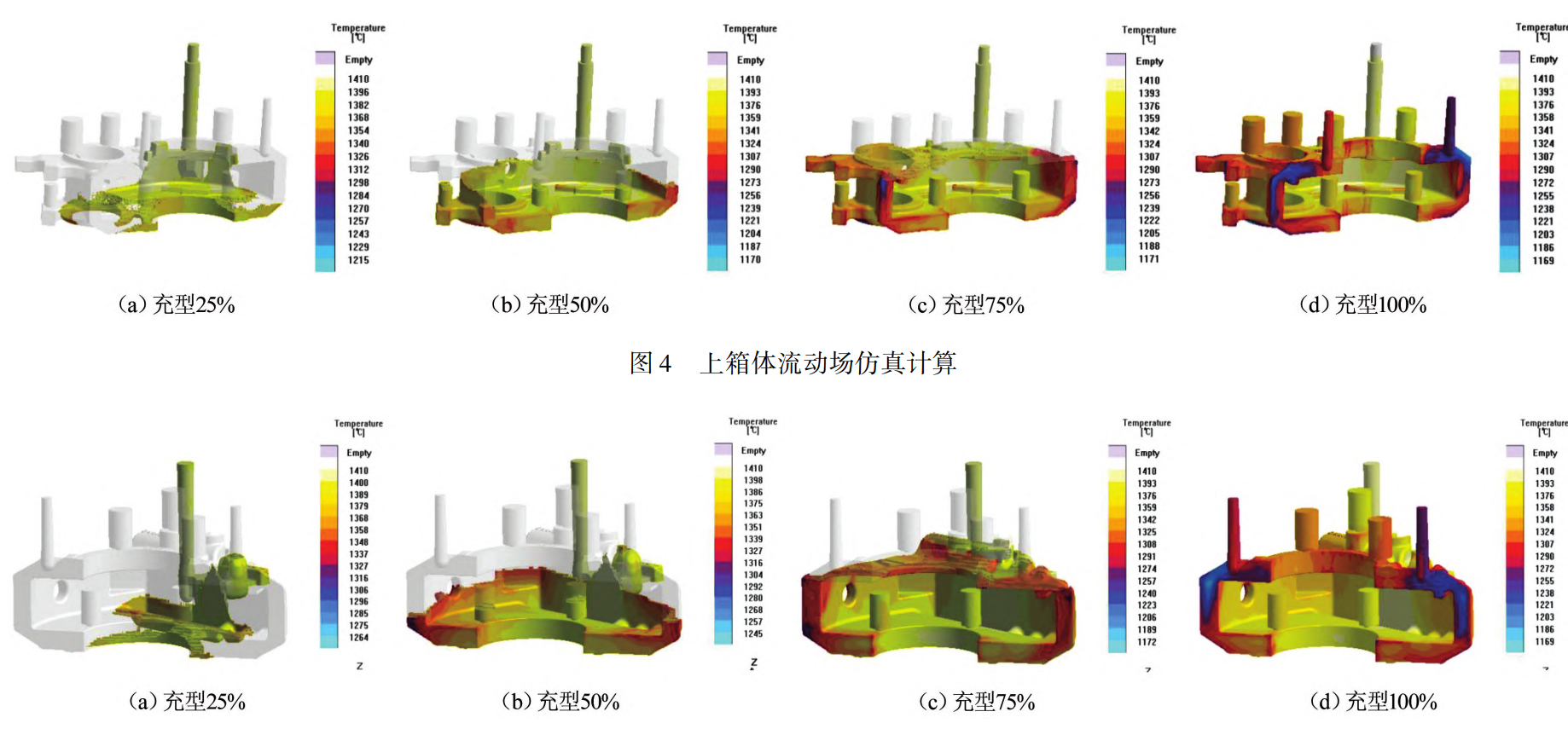

As shown in Figure 2 and Figure 3, through the simulation calculation of the flow field of the upper and lower boxes, it is found that when the ductile iron castings are filled with 25%, 50%, 75% and 100% of the mold, the temperature field in the thin-walled area of the whole box is relatively uniform, there is no isolated low temperature area, there is no risk of cold shut and insufficient filling defects, and the whole filling process is very stable, there is no splash and air entrainment, and the design of the ductile iron casting process is reasonable.

4. Smelting process

Rust, floating sand and oil stains on the surface of pig iron, scrap steel and return charge shall be removed when preparing the charge, and alloys such as nodulizer and inoculant shall be dried to reduce inclusions in molten metal and improve purity.

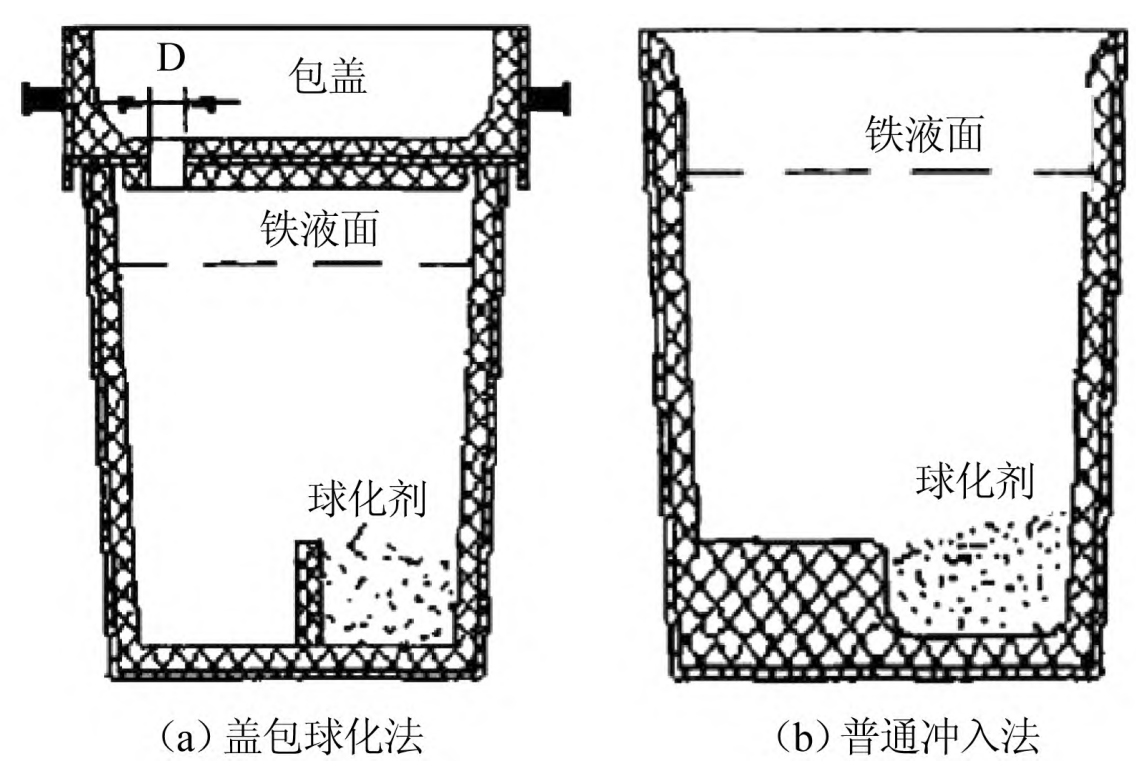

The pouring temperature plays an important role in the filling ability of molten metal. The higher the pouring temperature is, the better the filling ability is. In a certain temperature range, the filling capacity increases linearly with the increase of pouring temperature. However, if the pouring temperature is too high, it is easy to oxidize the molten metal and produce oxidation slag inclusion defect. The melting temperature is set at 1520 ℃, and the capping spheroidizing process is adopted, and the pouring temperature is 1440 ℃. The advantages of capping spheroidization are as follows compared with the ordinary penetration method:

(1) The temperature loss of molten metal during the capping spheroidizing process is small. When the ordinary spheroidizing bag (1t) is used for spheroidizing, the temperature drop is about 120 ℃, while the capping spheroidizing can be reduced to about 80 ℃. Under the premise of the same pouring temperature, the melting temperature can be reduced by 40 ℃ to achieve the effect of energy saving.

(2) Covering spheroidization can reduce the splashing of molten metal during spheroidization, improve the production environment in the spheroidization treatment area, and reduce the safety accidents caused by the splashing of molten metal.

(3) Since there is no molten metal splashing during the spheroidizing treatment of the cover, the pouring ladle can be moved to the pouring position of the ductile iron castings to remove slag during the spheroidizing reaction, which reduces the pouring time of the ductile iron castings, improves the pouring efficiency, is conducive to reducing the spheroidizing decay defects, and improves the spheroidizing grade. Schematic diagram of capping spheroidization method and common penetration method is shown in Figure 4.

5. Small batch trial production

According to the above process, a total of 24 sets of gear boxes have been trial-produced. The ductile iron castings have no casting defects such as cold shut, shrinkage porosity, slag inclusion, etc. The physical and chemical properties, X-ray flaw detection and wet fluorescent magnetic particle flaw detection of the ductile iron castings meet the technical requirements, and the qualification rate of the ductile iron castings reaches 100%.