Digital casting with computer simulation as the core has been widely used in the field of casting. With the development of computer technology and simulation analysis software, casting simulation technology has begun to be applied to actual production processes, resulting in significant changes in traditional casting process design patterns. Steering knuckle steel casting is a key component in the steering system of a wheeled vehicle. The internal quality requirements of this product are high, and no defects are allowed in the axial part after machining. Due to the limitation of the product structure, the production was carried out according to the original casting process. During the machining process, it was found that there were casting defects such as sand inclusion in the R85 mm circular arc with a large hot spot, mainly concentrated on the lower plane of the R85 mm circular arc, and the casting rejection rate reached 21%. This article uses casting simulation technology to optimize process design, significantly improving defects such as sand inclusions in steering knuckle products after machining, and continuously improving the quality qualification rate of steering knuckle products.

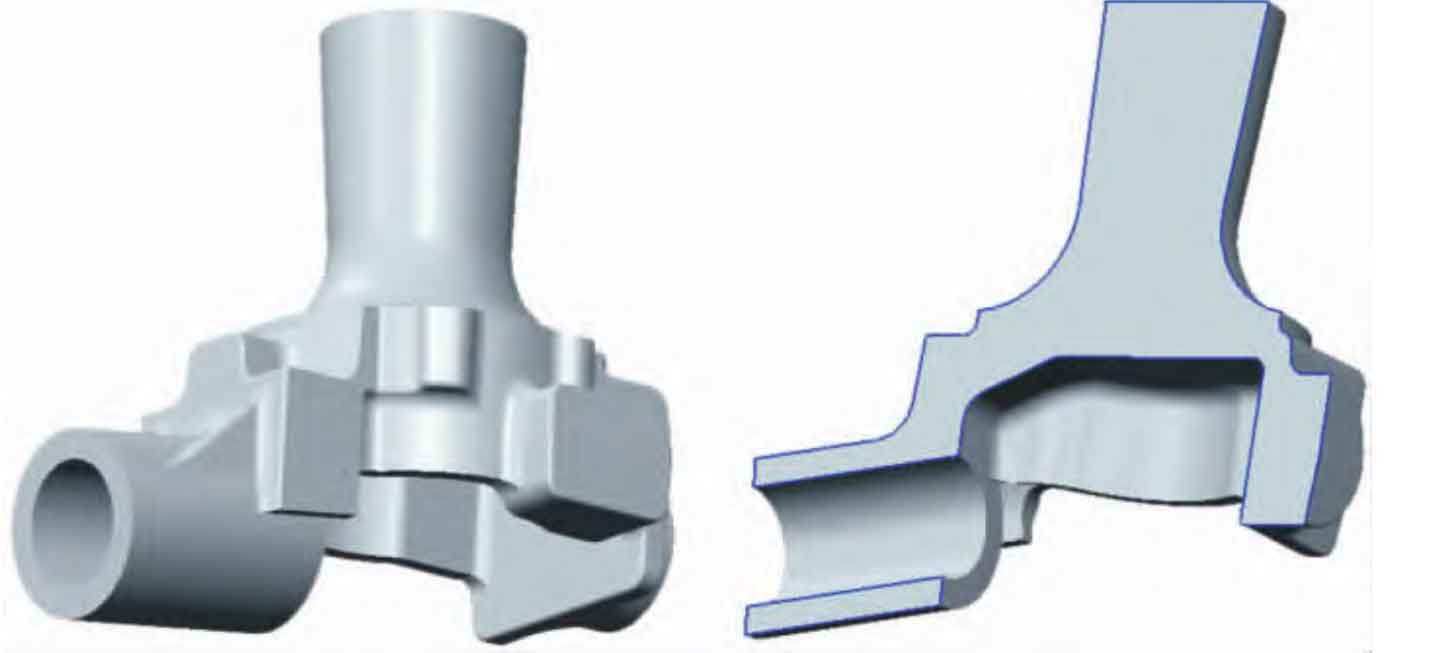

Steering knuckle steel casting is a key component in the steering system of a wheeled vehicle, with an average mass of about 85 kg and an overall dimension of 465 mm × 266 mm × 444 mm, a small part in a box type structure. The three-dimensional view of the steering knuckle steel casting is shown in Figure 1. After machining, the internal quality requirements for this product are high, and the casting process design is difficult. The chemical composition is shown in the table.

| Type of steel | C | Si | Mn | P | S | Fe |

| ZG30Mn | 0.29-0.36 | 0.40-0.80 | 1.30-1.90 | ≤0.040 | ≤0.040 | Bal. |

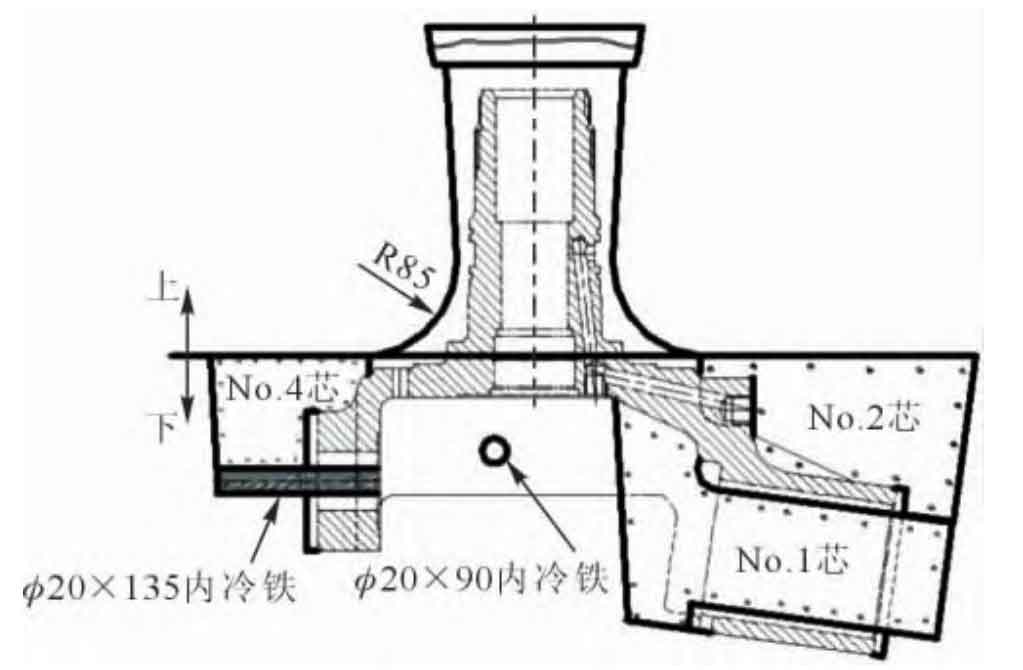

The DS80 ester hardened sodium silicate sand automatic molding production line is used for the molding production of steering knuckle steel castings. The process flow includes box setting, sand mixing, vibration compaction, surface drying, mold release, core lowering, box closing, and pouring. The core is made of highly collapsible inorganic binder sodium silicate sand, and carbon dioxide assisted hardening. According to the product structure of the steering knuckle steel casting, the mold is divided at the bottom end of the R85 mm circular arc. The complex structure below the parting surface is located in the lower box. The lower box is designed with four cores to form a casting inner cavity structure, and the rest are arranged on the upper box, with the uppermost end of the upper box φ 300 mm/ φ 180 mm × 210 mm open riser, used for sand collection, exhaust, and feeding, using a central pouring system, and set at the tail boss φ 20 mm × 135 mm inner chilled iron and appropriate amount of special sand, set at the middle support platform φ 20 mm × 90 mm inner chill iron and appropriate amount of special sand. The upper box is designed as an open drawing process. In order to facilitate mold lifting operations, the upper model adopts a “split” design at the intersection of R85 mm and the draft angle, and the middle design of the split tooling is φ 50 mm × 55 mm groove, the middle design of the fixed tooling of the upper model is φ 49.5 mm × A 50 mm protrusion is used to manually separate the upper model from the tooling during modeling operations. The groove is used to closely cooperate with the convex part of the fixed tooling to achieve the purpose of fixing the tooling, as shown in Figure 2.

The process layout of steel castings is one type with two parts, and the gating system adopts an “open” design. The model shares one sprue, and the size of the sprue is designed as φ 50 mm × 400 mm; 1 cross runner, designed to be 45 mm/50 mm in size × 45 mm; 2 internal gates, designed to be 35 mm/45 mm in size × 30 mm, with a pouring system cross-sectional ratio of 1.00: 1.09: 1.22. Liquid metal is injected into the mold cavity through an internal runner, with a pouring temperature of 1560-1580 ℃ and a pouring time of 18-33 seconds. A three-dimensional model of the steering knuckle casting process is shown in Figure 3.