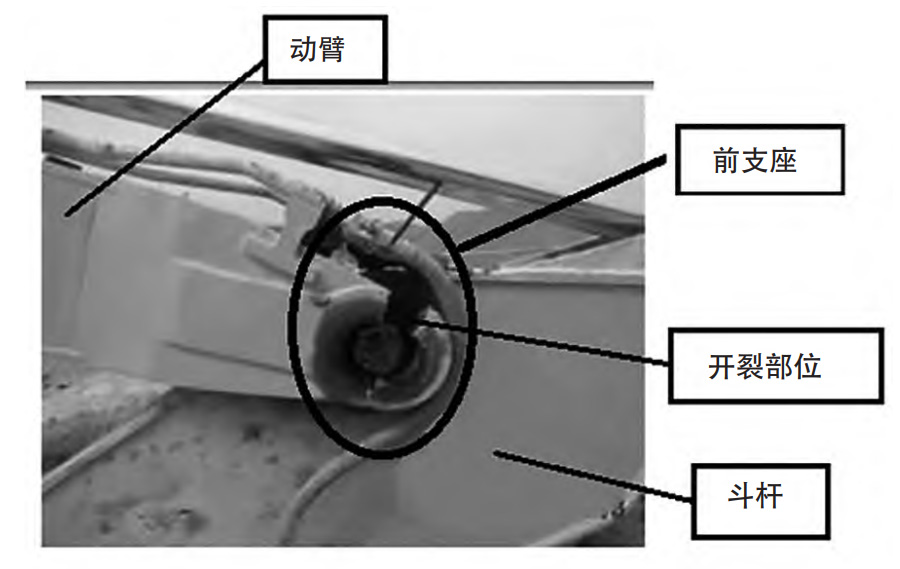

The production process of front support steel castings is as follows: molding – melting – casting – unpacking – sand cleaning – heat treatment (normalizing) – rough machining of holes and end faces – inspection – painting. From the figure, it can be seen that the front support steel casting, as a part of the boom, needs to have good welding performance when welded to the boom plate. The carbon equivalent should not be too high, otherwise a preheating process needs to be added. The front support steel castings bear a large working load and have high requirements for strength and fatigue performance. Therefore, the front support steel castings are made of SCW550H steel. The chemical composition is shown in Table 1.

| Steel grade(%) | C | Si | Mn | Mo | P | S | Cr | Cu | Ni | Ceq |

| SCW550H | 0.16~0.21 | ≤ 0.80 | 1.20~1.50 | ≤ 0.20 | ≤ 0.03 | ≤ 0.025 | ≤ 0.30 | — | 0.40~0.70 | ≤ 0.44 |

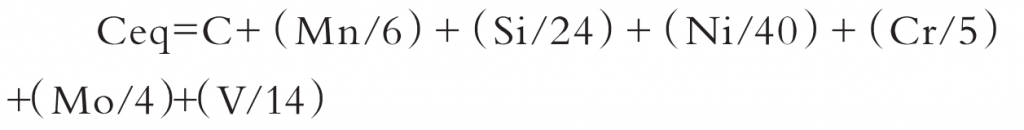

Calculate the carbon equivalent according to the formula, taking the maximum value. The requirements for its mechanical properties are shown in Table 2.

The mechanical performance parameters in Table 2 are applicable to steel castings with a thickness of less than 150mm. When the thickness of the steel casting exceeds 150mm, the yield strength specified in Table 2 is for design purposes only. The heat treatment adopts normalizing, and the metallographic structure is required to be ferrite+pearlite. There should be no abnormal structures such as Weinsteinite and residual cast structure, and the grain size grade should be greater than or equal to 6.

| Cast steel grade | Tensile strength/MPa | Yield strength/MPa | Elongation rate/% | Impact absorption energy/J | Hardness/HB |

| SCW550H | ≥ 550 | ≥ 355 | ≥ 22 | ≥ 27 | 146~196 |