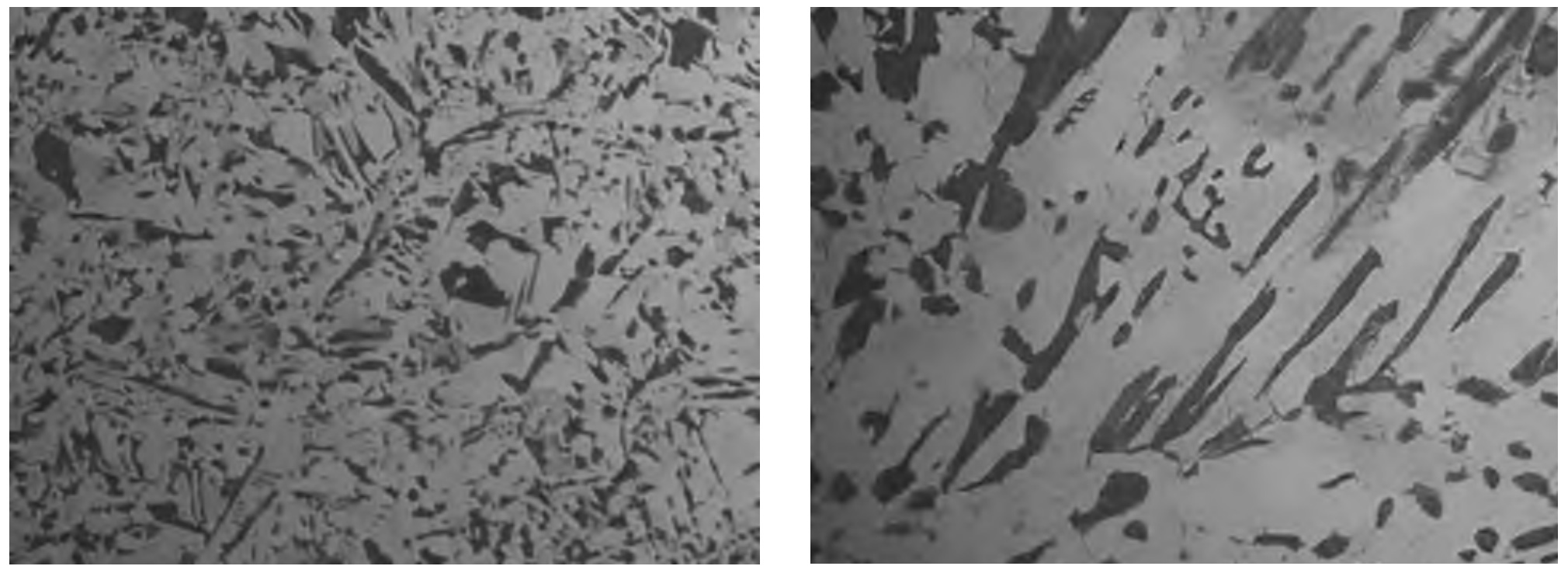

The fracture location is at the hole of the front support steel casting, where the design safety factor is relatively high. Other products with similar structures have not experienced such fracture failure failures. From the appearance of the fracture surface, it is suspected that the metallographic structure here does not meet the design requirements. Cut and sample from below the fracture surface for metallographic analysis. The metallographic condition under microscope magnification of 100 times is shown in Figure 1. The metallographic condition under microscope magnification of 500 times is shown in Figure 2.

From Figures 1 and 2, it can be observed that there is a feathery Weinstein structure with uneven microstructure and a grain size grade of 5. The Weinstein structure and coarse grains in steel castings are common structures in steel castings due to a series of factors such as casting temperature, cooling rate, and size of the castings during the casting process. During the heat treatment process, it is necessary to eliminate the Vickers structure and refine the grains. If the normalizing temperature is too high, the cooling rate is too fast, and the insulation time is not enough during heat treatment, it will cause the Weinstein structure to be unable to be effectively eliminated, leading to a significant decrease in the plasticity and impact toughness of the steel casting for the front support of the boom.

According to relevant technical requirements, the front support steel castings must not have abnormal structures such as Weinsteinite and residual cast structure, and the grain size level must be greater than or equal to level 6. In response to this unqualified item, after investigation, it was found that the normalizing time for the supplier to manufacture this piece was only 2 hours, far lower than the 4 hours calculated based on the traditional insulation coefficient, and also lower than the 3 hours calculated based on the normalizing economic insulation coefficient. Due to the short normalizing insulation time, the residual Weinsteinite structure during the casting process of steel castings cannot be effectively eliminated and the grains cannot be refined. Due to the low microstructure and grain size grade of Weinstein, the mechanical properties of steel castings have significantly decreased.