Steel casting offers a versatile and reliable manufacturing process that enables the creation of complex and intricate components. Designing for steel casting requires a unique blend of technical expertise and creative thinking. This article explores the art of designing for steel casting, highlighting the advantages, considerations, and innovative approaches that allow designers to unleash their creativity while maximizing the benefits of this manufacturing technique.

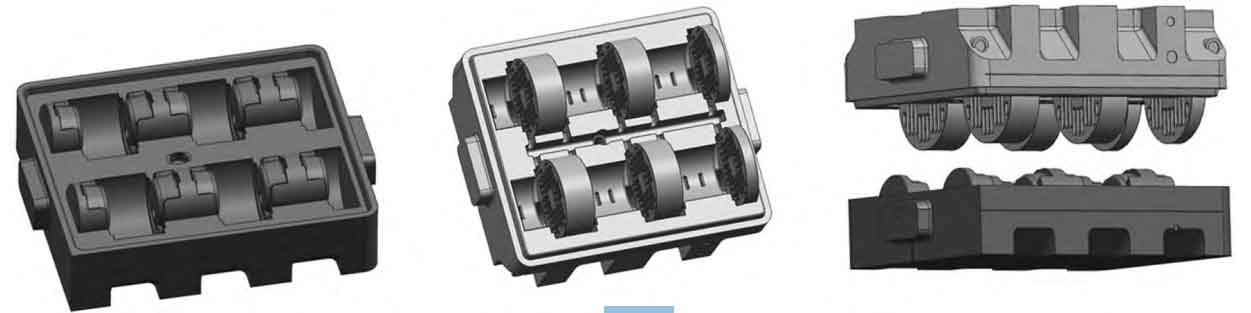

- Leveraging Design Freedom: Steel casting provides designers with significant freedom to create intricate and complex shapes that are not easily achievable with other manufacturing processes. The ability to incorporate intricate details, fine features, and internal cavities opens up a world of design possibilities. Designers can push the boundaries of creativity, resulting in visually appealing and functionally optimized components.

- Design for Manufacturability: While steel casting offers design freedom, it is crucial to consider manufacturability during the design phase. Collaboration between designers and casting experts is essential to ensure that the design can be successfully translated into a cast component. Factors such as parting lines, draft angles, and gating systems need to be considered to facilitate the casting process and ensure high-quality results.

- Optimal Material Selection: Choosing the right steel alloy is critical to achieving the desired performance characteristics of the cast component. Designers must consider factors such as mechanical properties, corrosion resistance, and heat resistance when selecting the appropriate steel grade. Collaborating with material specialists can provide valuable insights into the material properties and compatibility with the intended application.

- Balancing Complexity and Cost: Designing for steel casting involves striking a balance between complexity and cost. Complex designs may increase production time, material consumption, and post-casting processing requirements, leading to higher costs. Designers need to evaluate the trade-offs between the desired complexity and the practicality of manufacturing to optimize both the design and the cost-effectiveness of the casting process.

- Simulation and Optimization: Utilizing advanced simulation tools can greatly aid the design process for steel casting. Casting simulation software enables designers to visualize and optimize the filling, solidification, and cooling processes, helping to predict and address potential defects or issues. By simulating different design iterations and evaluating their impact on the casting process, designers can make informed decisions that result in higher-quality castings.

- Innovations and Future Trends: The art of designing for steel casting continues to evolve with technological advancements. Additive manufacturing techniques, such as 3D printing, are being integrated with traditional casting processes, allowing for the creation of hybrid components that combine the benefits of both methods. Digital design tools, virtual reality, and artificial intelligence are also shaping the future of steel casting design, enabling faster prototyping, optimization, and customization.

Designing for steel casting is a captivating blend of technical expertise and creative expression. By embracing the design freedom offered by steel casting and considering manufacturability, material selection, and cost optimization, designers can create visually stunning and functionally superior components. Collaboration with casting experts and the utilization of advanced simulation tools empower designers to explore new horizons and push the boundaries of what is possible in the world of steel casting. With the ongoing advancements in technology and innovative approaches, the art of designing for steel casting will continue to flourish, enabling the creation of remarkable and impactful cast components.