Decarburization is the loss of carbon from the surface or near-surface layers of a material during heat treatment. It can significantly affect the mechanical properties and performance of heat-treated components, particularly those requiring high surface hardness. To prevent decarburization and protect against carbon loss during heat treatment, consider the following preventive measures:

- Controlled Atmosphere: Utilize a controlled atmosphere during heat treatment to create a protective environment that prevents or minimizes contact between the material surface and oxygen. Common methods include:

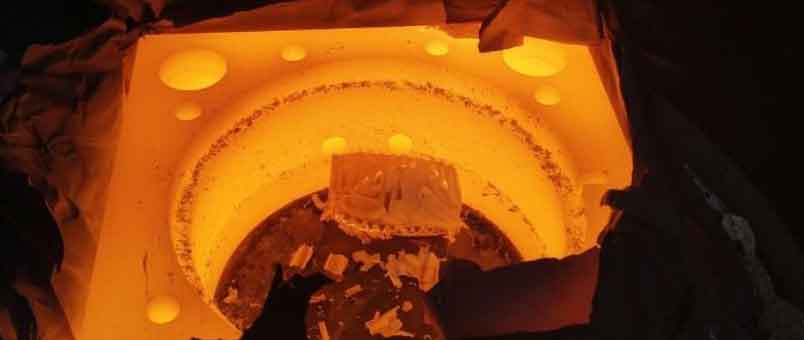

- Pack carburizing: Surround the components with a carbon-rich medium, such as charcoal or gas-releasing compounds, to create a carburizing atmosphere.

- Gas or vacuum carburizing: Use a controlled gas atmosphere with a high carbon potential or conduct carburizing in a vacuum chamber.

- Protective Coatings: Apply protective coatings on the component surface before heat treatment to serve as a barrier against oxygen contact. Some common coating materials include:

- Pack cementation: Apply a diffusion coating, such as a mixture of powdered metals and activators, to the component surface prior to heat treatment.

- Physical vapor deposition (PVD) or chemical vapor deposition (CVD): Deposit a thin protective layer, such as titanium nitride or chromium carbide, onto the component surface.

- Inert Gas Blanketing: Utilize inert gas blanketing techniques, such as nitrogen or argon, to create an oxygen-free environment around the components during heat treatment. This helps prevent decarburization by minimizing oxygen contact.

- Proper Sealing and Enclosure: Ensure proper sealing of the heat treatment furnace or chamber to prevent the ingress of ambient air, which can lead to decarburization. Regularly inspect and maintain the seals, gaskets, and insulation to maintain a controlled atmosphere.

- Controlled Heating and Cooling Rates: Implement controlled and uniform heating and cooling rates during the heat treatment process. Rapid or uneven heating and cooling can increase the likelihood of decarburization. Follow recommended heating and cooling profiles specific to the material and heat treatment process.

- Optimized Process Parameters: Optimize the process parameters such as temperature, time, carbon potential, and quenching medium to achieve the desired heat treatment results without excessive carbon loss. Ensure the process parameters align with the specific material and component requirements.

- Surface Preparation: Thoroughly clean the component surface before heat treatment to remove any contaminants, such as oils, greases, or dirt, which can accelerate decarburization. Utilize suitable cleaning methods such as degreasing or acid cleaning.

- Monitoring and Quality Control: Implement regular monitoring and quality control measures to detect and address any deviations from the desired heat treatment conditions. This includes using non-destructive testing techniques, metallographic examination, hardness testing, and microstructure analysis to evaluate the extent of decarburization.

It is important to note that the prevention of decarburization depends on the specific material, heat treatment process, and component requirements. Collaborating with heat treatment experts, metallurgists, and process engineers can provide valuable guidance in implementing appropriate preventive measures and optimizing the heat treatment process to minimize decarburization.