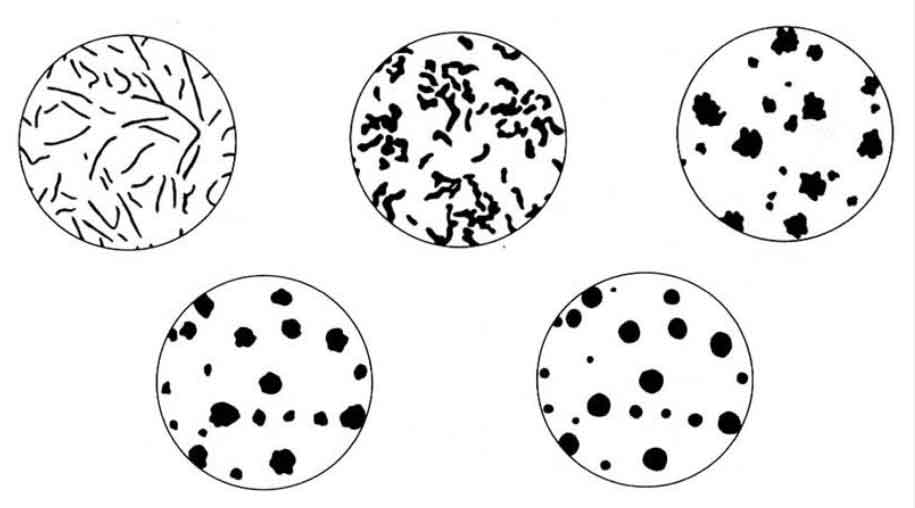

Spheroidal Graphite Iron, also known as ductile iron or nodular iron, is a type of cast iron that has gained significant popularity and importance due to its unique properties and wide range of applications. Spheroidal Graphite Iron is characterized by the presence of graphite nodules or spheroids, which provide excellent mechanical properties, making it a versatile material for various industries. Let’s explore the applications and innovations in Spheroidal Graphite Iron technology.

- Automotive Industry: Spheroidal Graphite Iron is extensively used in the automotive sector due to its superior strength, toughness, and excellent machinability. It finds applications in engine components such as crankshafts, cylinder heads, pistons, and camshafts. Spheroidal Graphite Iron’s ability to withstand high cyclic loading and thermal stress makes it an ideal choice for these critical components.

- Heavy Machinery: Spheroidal Graphite Iron’s exceptional mechanical properties make it suitable for heavy machinery applications. It is commonly used in manufacturing components like gears, bearing caps, brackets, and hydraulic components. Spheroidal Graphite Iron’s high wear resistance and ability to handle high loads make it a reliable choice for demanding industrial applications.

- Pipe and Fitting Industry: Spheroidal Graphite Iron pipes and fittings are widely used in water supply, sewage, and drainage systems. The corrosion resistance, high ductility, and long-term reliability of Spheroidal Graphite Iron make it an excellent choice for underground and submerged applications. Spheroidal Graphite Iron pipes can withstand internal and external pressure, making them suitable for a wide range of fluid transportation systems.

- Construction Industry: Spheroidal Graphite Iron is also utilized in the construction sector for applications such as manhole covers, gratings, and heavy-duty supports. Its high strength and impact resistance make it an ideal material for these infrastructure components, ensuring durability and safety.

- Renewable Energy Sector: With the growing focus on renewable energy, Spheroidal Graphite Iron has found its place in wind turbine manufacturing. Spheroidal Graphite Iron is used to produce turbine hubs, rotor hubs, and other structural components due to its high strength, fatigue resistance, and cost-effectiveness. It enables the construction of larger and more efficient wind turbines.

Innovations in Spheroidal Graphite Iron Technology:

- Alloying and Heat Treatment: Researchers are continuously working on developing new alloys and optimizing heat treatment processes to enhance the mechanical properties of Spheroidal Graphite Iron. This includes improving strength, toughness, and corrosion resistance to expand its application range.

- Lightweighting: Efforts are being made to reduce the weight of Spheroidal Graphite Iron components while maintaining their mechanical properties. This is achieved by optimizing the microstructure, utilizing advanced casting techniques, and exploring new alloying elements.

- Advanced Casting Techniques: Innovations in casting technologies, such as computer simulation, modeling, and 3D printing, are being applied to Spheroidal Graphite Iron production. These techniques enable more precise control over the casting process and the production of complex geometries, resulting in improved component performance.

- Surface Treatment: Surface modification techniques like coatings and treatments are being explored to enhance the wear resistance, corrosion resistance, and fatigue life of Spheroidal Graphite Iron components. These advancements increase the lifespan and performance of Spheroidal Graphite Iron in various applications.

The power of Spheroidal Graphite Iron lies in its unique combination of strength, toughness, and versatility. Ongoing research and innovations continue to expand its applications and improve its properties, making it a vital material in the field of cast iron technology.