Introduction

In the field of aviation jet engine, naval gas turbine, industrial gas turbineturbines are usually driven by high-temperature gases in many fields,precision casting such as power generation and aerospace.As an important component of turbines, the blades of the turbine need to withstand high temperatures,The harsh environment of hot corrosion (typical gas turbine operating temperature exceedsHigh temperature alloys have good oxidation resistance, precision casting thermal stability, fatigue resistance, and good creep rupture resistance. Therefore, it isIt has been widely used in this environment.

K213 is an iron nickel chromium based cast high-temperature alloy, in whichForming Al and Ti γ’ Phase, and achieved precipitation strengthening effect, precision casting with WPerform solid solution strengthening with trace amounts of B to strengthen grain boundaries. The alloy castingExcellent craftsmanship, with good comprehensive performance below 750 ℃.

In recent years, high-temperature alloy components have tended towards precision and thin-walling, due toThis will put forward higher requirements for precision casting technology. Traditional experimentersArt has problems such as high trial and error costs and long cycles, while computer-aided designPlanning can greatly reduce trial and error costs and shorten the process design cycle. domesticThere have been precedents of using computers to simulate the solidification process of blade casting.The Iron and Steel Research Institute adopts computer simulation of high-temperature alloy precision casting, which is the most advancedThe optimal process plan has been finalized, significantly reducing casting defects and loweringReduced production costs. precision casting Shenyang University of Aeronautics and Astronautics adopts finite element analysisSimulated the filling solidification of K438 alloy liquid in investment casting processThe process has determined the optimal casting system and process. Harbin IndustryThe university simulated the forming process of TiAl based alloy blade suction casting and analyzed itThe causes of defects in the blades during the filling and solidification process were investigated and analyzedClose verification. There are also many scholars abroad who combine high-throughput methods with numerical methodsCombining value simulation and applying it to optimize precision casting process parametersIn order to quickly and accurately optimize key process parameters and improve the quality of castingsComprehensive performance.

Regarding the complex shape and precision casting process of high-temperature alloy bladesProblems such as defects are prone to occur in the casting process, and MAGMA casting simulation software is usedApplication of K213 High Temperature Alloy in Precision Investment Casting of Typical BladesThe filling and solidification process mainly affects the fluid velocity of the molten liquid during the filling processDegree field distribution, solid fraction distribution during solidification process, temperature field distribution, precision casting voidsSimulate research on distribution and other factors,precision casting by analyzing the locations where casting pores are prone to occurDetermine and verify the reliability of the designed pouring system for on-site testing andProvide reliable theoretical basis for production.

Select K213 casting high-temperature alloy as the base alloy for testing, and its transformationThe learning components are listed in Table 1. The melting point of K213 alloy is 1 324 to 1 361℃, density ρ = 8.14 g/cm3When the expansion coefficient is between 20-800 ℃For 18.61 × 10-6℃ -1.

Using MAGMA casting simulation software for K213 alloy bladesSimulate the casting process and analyze the casting process through filling and solidification processesThe formation and distribution of temperature field and defects during the manufacturing process are based on actual productionProvide correct guidance on process methods. Using gravity casting, gravity plusThe speed is 9.8 m/s. The basic parameters include a weight factor of 0.8 and a relaxation factor1.6, initial time step of 0.000 1 s, casting and air,precision casting casting and castingThe heat transfer coefficients between molds are all 0.023, and the casting temperature is 1550 ℃.

The casting is a blade with complex shapes, using SolidWorks 3D simulationThe body modeling software is used to shape the entire pouring system, using a top pouring methodPour 4 alloy blades at once, with a single blade mass of 3 kg,precision casting through pouringThe mouth and transverse runner are used to supplement and shrink the solidification process of the blade. Using MAGMACasting simulation software is used for grid division, with a grid parameter of 1 mm selected.

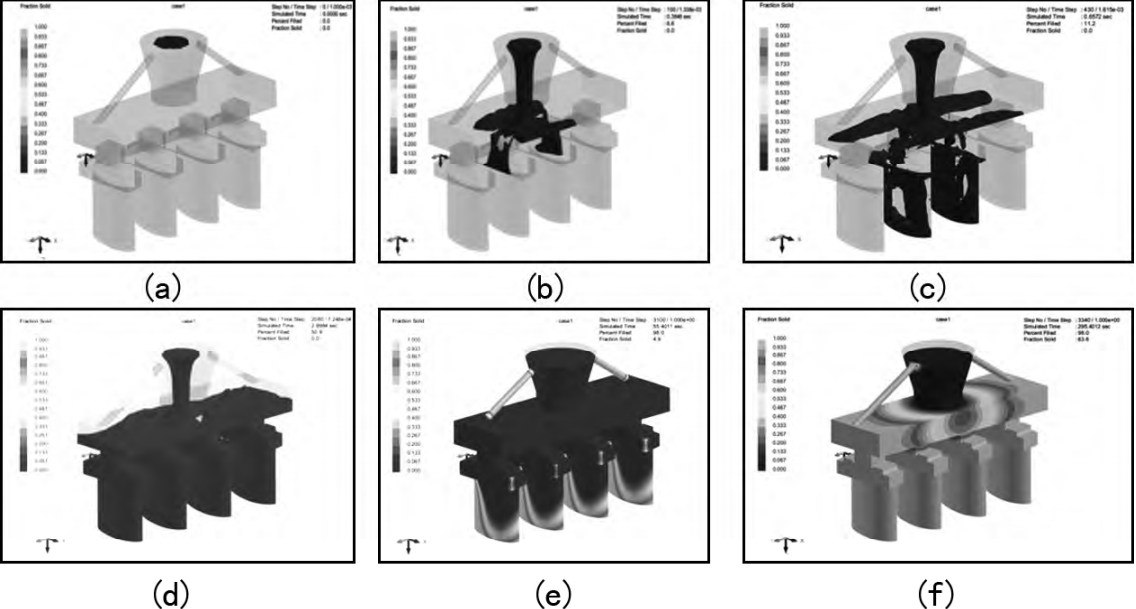

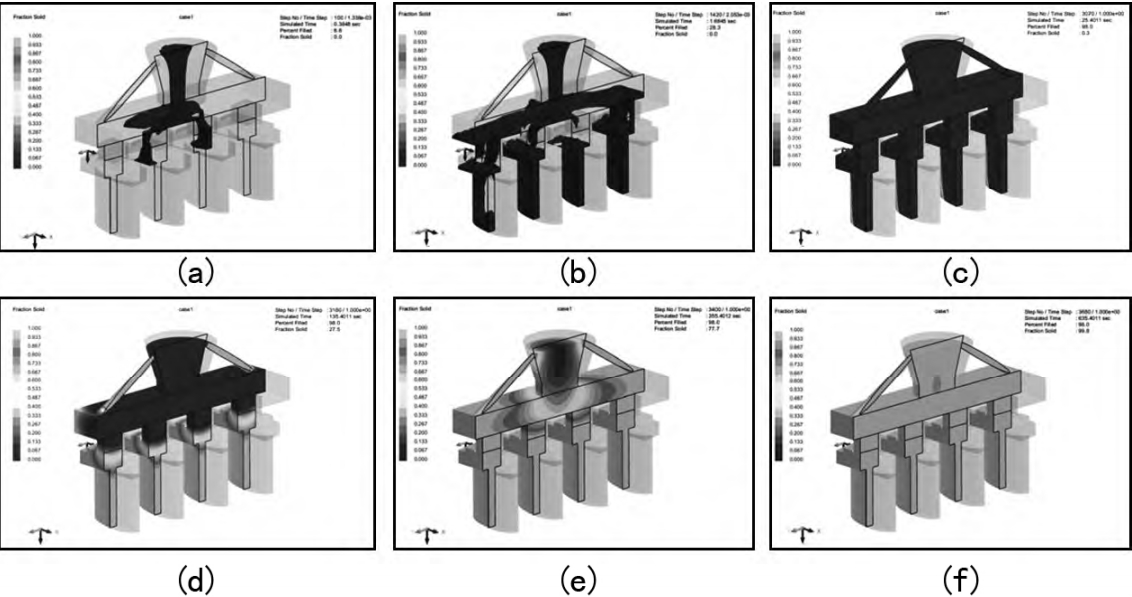

The solid-phase ratio during the filling process, where the vertical direction shown in Figure 3The cross-sectional view can observe the distribution of solid phase fraction inside the blades and pouring system.precision casting As shown in the figure, the alloy liquid is always in the liquid state during the pouring process at the blade siteThe state can achieve complete punching of the blade part, with punching completed in 15 seconds and punching completed in 25 secondsIt begins to solidify at the edge of the blade. precision casting After the blade solidifies, the transverse runner opensThe initial solidification occurs, and the final solidification occurs at the connection between the gate and the runnerAt the center, the final solidification area can be placed at the connection between the gate and the runner.

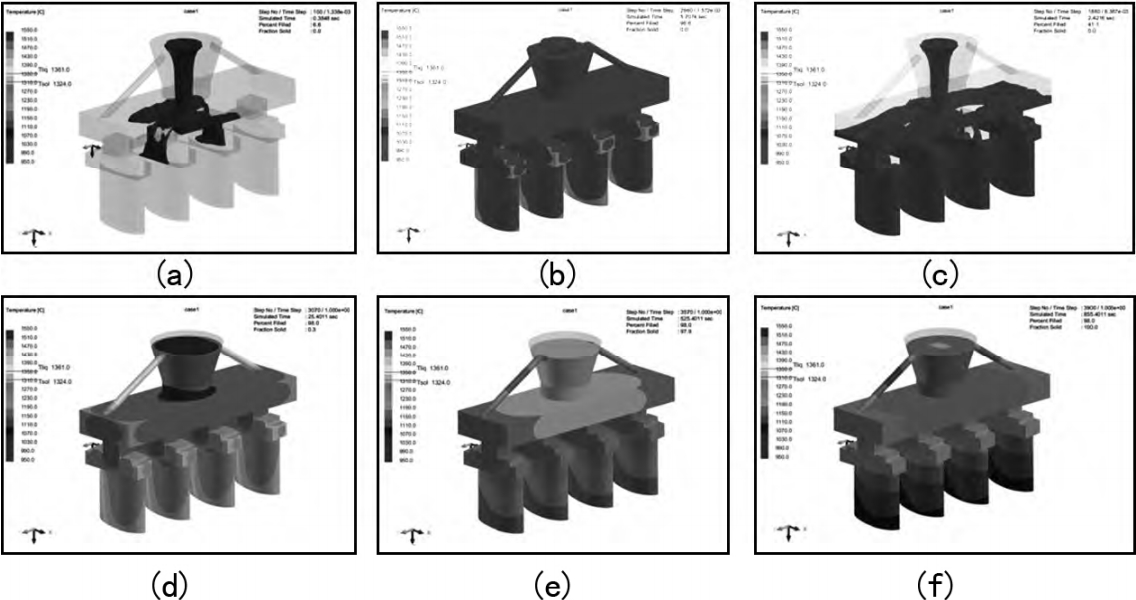

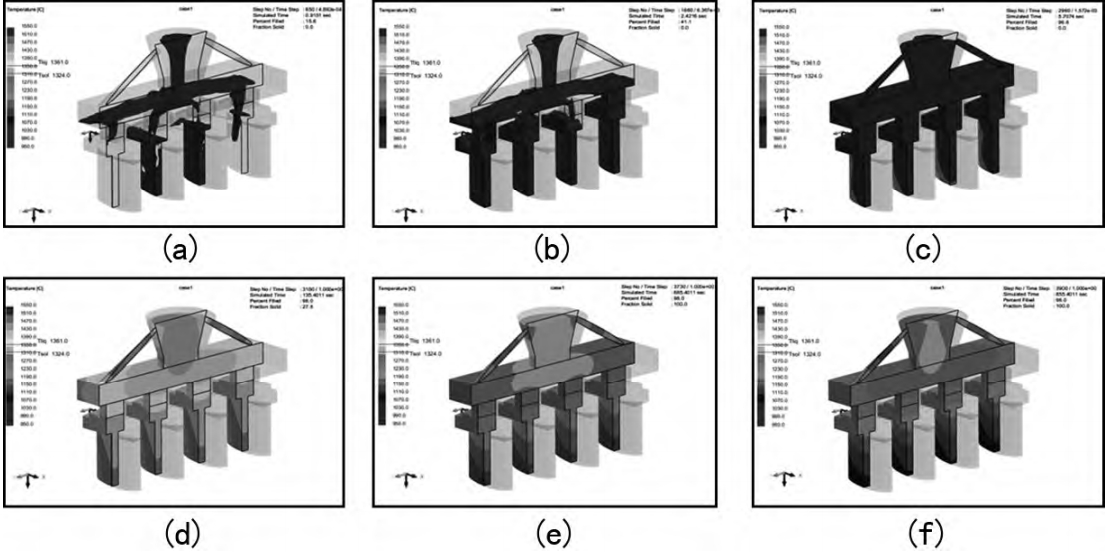

Temperature field distribution during pouring process, whereThe longitudinal sectional view can observe the temperature field inside the blades and pouring systemCloth. As shown in the figure, the alloy liquid remained in a high temperature state during the pouring process at the blade site, with a temperature of approximately 1500 ℃ throughout the entire process.precision casting After 3 seconds, the bladeAfter the stamping of the parts is completed, the cooling starts at the edge of the blade, with a minimum temperature of approximatelyAt 1400 ℃, it is still higher than the melting point of the alloy and less prone to defects. 15 second punchingAfter completion, the temperature in the edge area of the blade decreased to about 1230 ℃. junctionAccording to the combined analysis results, condensation begins at the edge of the blade at 25 secondsFixed, after 15 minutes,precision casting at the center position of the connection between the gate and the transverse gateThe temperature is still around 1300 ℃ and remains in a high temperature state, while the restThe temperature of all parts has dropped below the melting point. precision casting This indicates that the designed gate and cross sectionThe sprue can supplement and shrink the blade section.

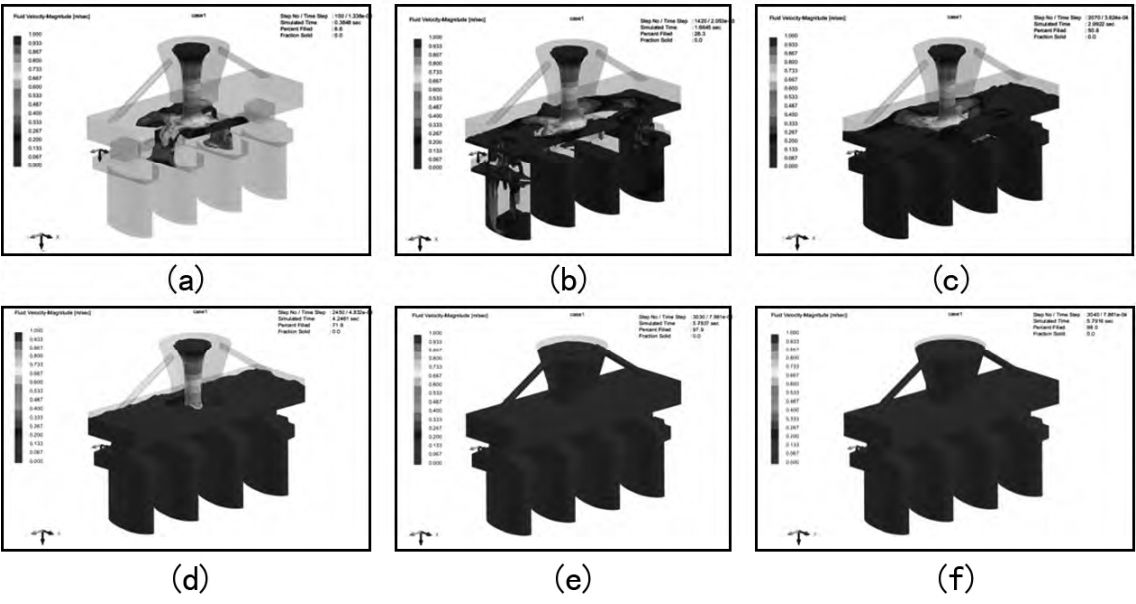

Simulation results of the velocity field during the filling process. As shown in Figure 6,At 3 seconds, the pouring of the blade was completed, but there was still disturbance at the edge of the bladeThere is a small amount of entrainment behavior in the two outermost blades. With the followingThe continuous pouring process will not cause casting defects due to this disturbance. precision casting fourAt s, the alloy flow in the blade area is completely stationary, and at 15 s, the casting is poured completelyAfter completion,precision casting it can be observed that there is a significant decrease in the liquid level of the gate, indicating that the gateThe transverse sprue has played a good role in filling and shrinking.

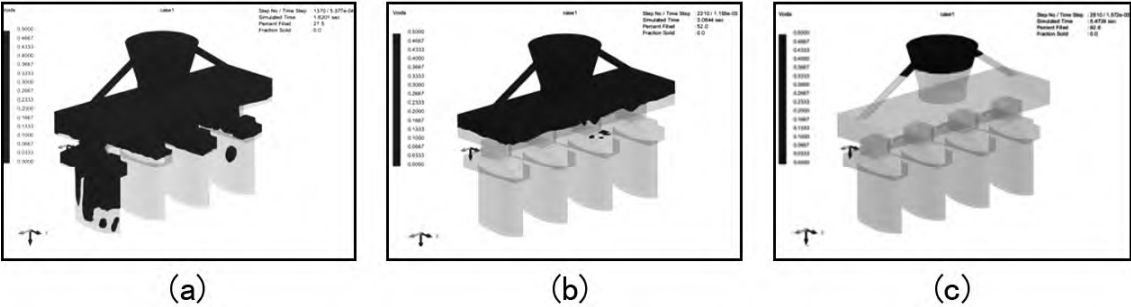

Simulation results of voids during the pouring process. It can be seen that during pouringDuring the pouring process, precision casting the center of the two outermost blades will be disturbed by the pouring processForming voids, but as pouring progresses, under the pressure of the molten metal,The gap continues to rise and eventually concentrates at the gate and runner.

conclusion

The focus of the article is on the filling of K213 high-temperature alloy in precision investment castingFluid velocity field during solidification process and solid phase fraction during solidification processMAGMA casting simulation was conducted on the distribution of fabric, temperature field, and void distributionThrough real simulation research and analysis of simulation results,precision casting the porosity of castings has been determinedThe possible locations have verified the reliability of the pouring system. conclusionBelow.(1) During the pouring process of the blade part, the alloy liquid is always in a liquid state,Can achieve complete punching of blade parts. After the blades have solidified, precision casting horizontallyThe sprue begins to solidify, and the final solidification occurs at the junction of the sprue and the transverse sprueThe center of the joint.(2) The temperature field simulation results indicate that after filling, the blade edgeThe edge first begins to cool down, and the temperature shows a gradient increase from the top of the blade to the gateAdd; The center position of the connection between the gate and the transverse gate is always at high temperatureThe temperature in other parts has dropped below the melting point.(3) The simulation results of the flow field and voids indicate that in the early stage of filling, the bladesThere is a small disturbance in the blade area, and at 4 seconds, the alloy flow in the blade area is completely staticStop; After the casting is poured, it can be observed that the liquid level at the riser has significantly decreasedIndications; Finally, the solidification voids are concentrated at the gate and transverse runner.precision casting The article clarifies the flow of K213 high-temperature alloy during solidification processThe evolution process of field and temperature field accurately predicts the occurrence of casting defectsLocation and severity. Therefore, it can be used for K213 high-temperature alloy bladesThe design of precision casting technology provides solid theoretical support for high-temperature alloysThe design of precision casting technology has important reference significance.