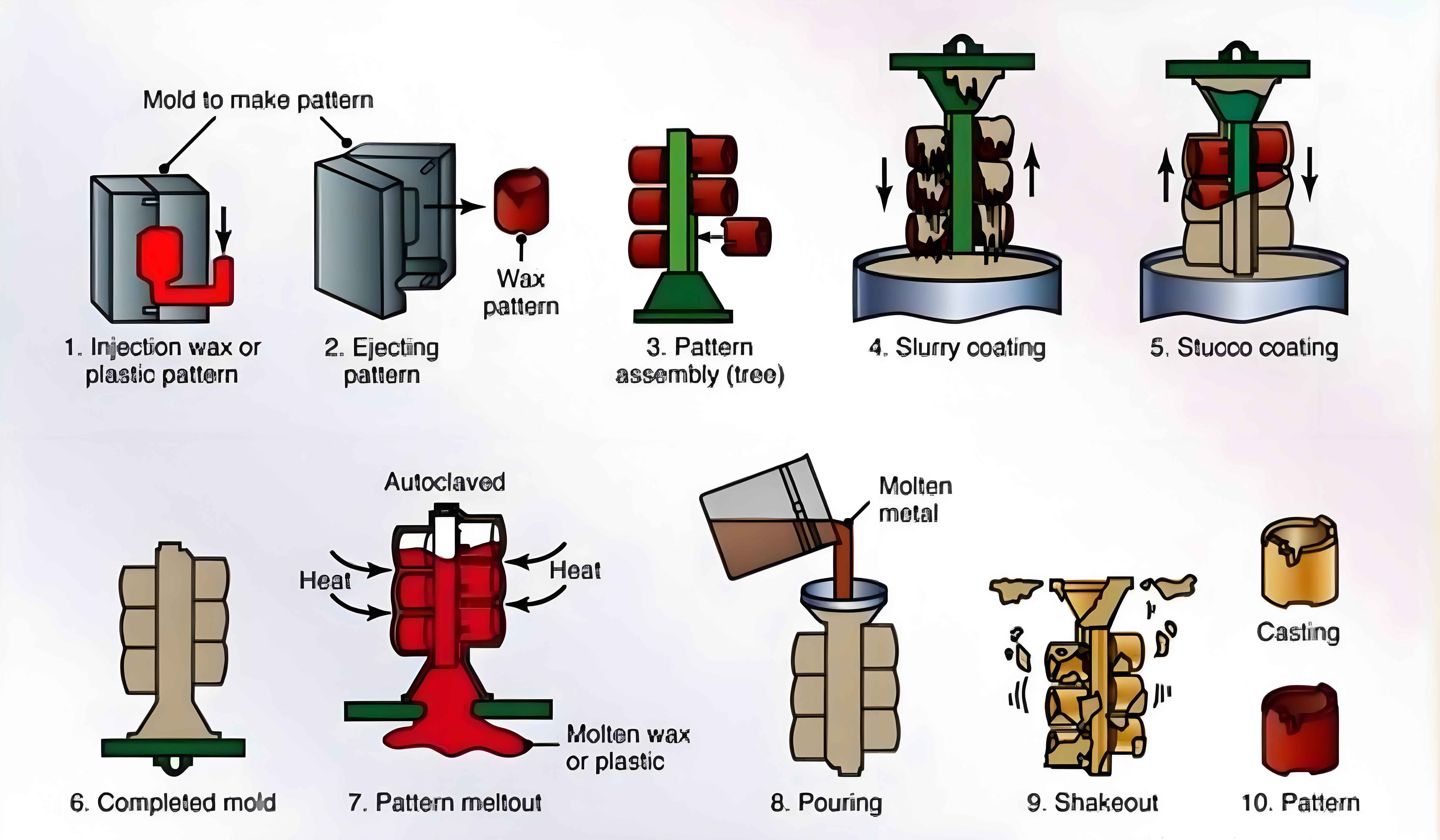

Investment casting, also known as lost-wax casting, is a precise and versatile process used in manufacturing complex metal parts. Incorporating sustainability into investment casting involves using eco-friendly materials and energy-efficient practices to reduce environmental impact. Here’s an overview of how sustainability can be achieved in investment casting:

Eco-Friendly Materials

- Biodegradable Waxes and Patterns:

- Use of biodegradable or bio-based waxes for creating the patterns.

- Alternative materials like PLA (polylactic acid), which are derived from renewable resources, can be used for 3D printing patterns.

- Recycled Metals:

- Utilizing recycled metals in the casting process reduces the need for virgin materials and minimizes mining activities.

- Ensuring the quality of recycled metals through proper sorting and refining processes.

- Environmentally Friendly Coatings:

- Adoption of water-based ceramic slurries and binders for shell building.

- Use of non-toxic and low-VOC (volatile organic compounds) coatings.

Energy-Efficient Practices

- Optimizing Energy Consumption:

- Implementing energy-efficient furnaces and kilns for melting and casting processes.

- Using waste heat recovery systems to utilize excess heat for other processes or heating needs.

- Process Optimization:

- Streamlining the casting process to minimize energy use, such as optimizing the mold preheating schedule and improving the efficiency of pattern removal.

- Employing simulation software to design molds and predict casting outcomes, reducing the need for trial and error and saving energy.

- Renewable Energy Integration:

- Incorporating renewable energy sources such as solar, wind, or biomass for powering the casting facilities.

- Installing solar panels on the roofs of manufacturing plants to supply clean energy.

Waste Reduction and Recycling

- Shell and Core Recycling:

- Recycling used ceramic shells and cores by crushing and reprocessing them for use in new molds.

- Implementing systems for collecting and reusing spent shell materials.

- Wax Recovery Systems:

- Installing wax recovery systems to reclaim wax from used molds and reuse it in future casting cycles.

- Reducing the amount of wax waste generated and lowering the demand for new wax.

- Scrap Metal Recycling:

- Recycling scrap metal generated during the trimming and finishing processes.

- Partnering with recycling companies to ensure proper handling and processing of metal waste.

Water Conservation

- Water Recycling Systems:

- Implementing closed-loop water systems to recycle water used in the investment casting process.

- Treating wastewater to remove contaminants and reuse it in the production cycle.

- Efficient Water Usage:

- Using water-efficient practices in cleaning and cooling processes.

- Monitoring water usage and implementing measures to reduce consumption.

Sustainable Facility Management

- Green Building Practices:

- Designing and constructing casting facilities with sustainable materials and energy-efficient designs.

- Incorporating natural lighting, efficient HVAC systems, and sustainable landscaping.

- Environmental Management Systems:

- Implementing ISO 14001 or similar environmental management systems to continuously improve environmental performance.

- Regularly auditing and reviewing environmental practices to ensure compliance and identify areas for improvement.

Research and Development

- Innovative Materials and Processes:

- Investing in research to develop new eco-friendly materials and more efficient casting processes.

- Collaborating with universities and research institutions to stay at the forefront of sustainable casting technologies.

- Employee Training and Awareness:

- Providing training programs for employees on sustainable practices and the importance of environmental conservation.

- Encouraging a culture of sustainability within the organization.

By adopting these eco-friendly materials and energy-efficient practices, the investment casting industry can significantly reduce its environmental footprint, contributing to a more sustainable future.