Ductile cast iron is a type of cast iron that features graphite nodules dispersed throughout its microstructure. These nodules play a crucial role in defining the material’s mechanical properties, particularly its fracture mechanics. This article explores the influence of graphite nodules on the fracture behavior of ductile cast iron, examining their impact on toughness, crack initiation, and propagation.

Introduction

Ductile cast iron is widely utilized in engineering applications due to its excellent combination of strength, toughness, and ductility. The presence of graphite nodules in the microstructure is a defining characteristic that significantly influences the material’s fracture mechanics. Understanding the role of these nodules is essential for optimizing the performance of ductile cast iron in critical applications such as automotive components, machinery parts, and pressure vessels.

Graphite Nodules and Microstructure

Formation of Graphite Nodules

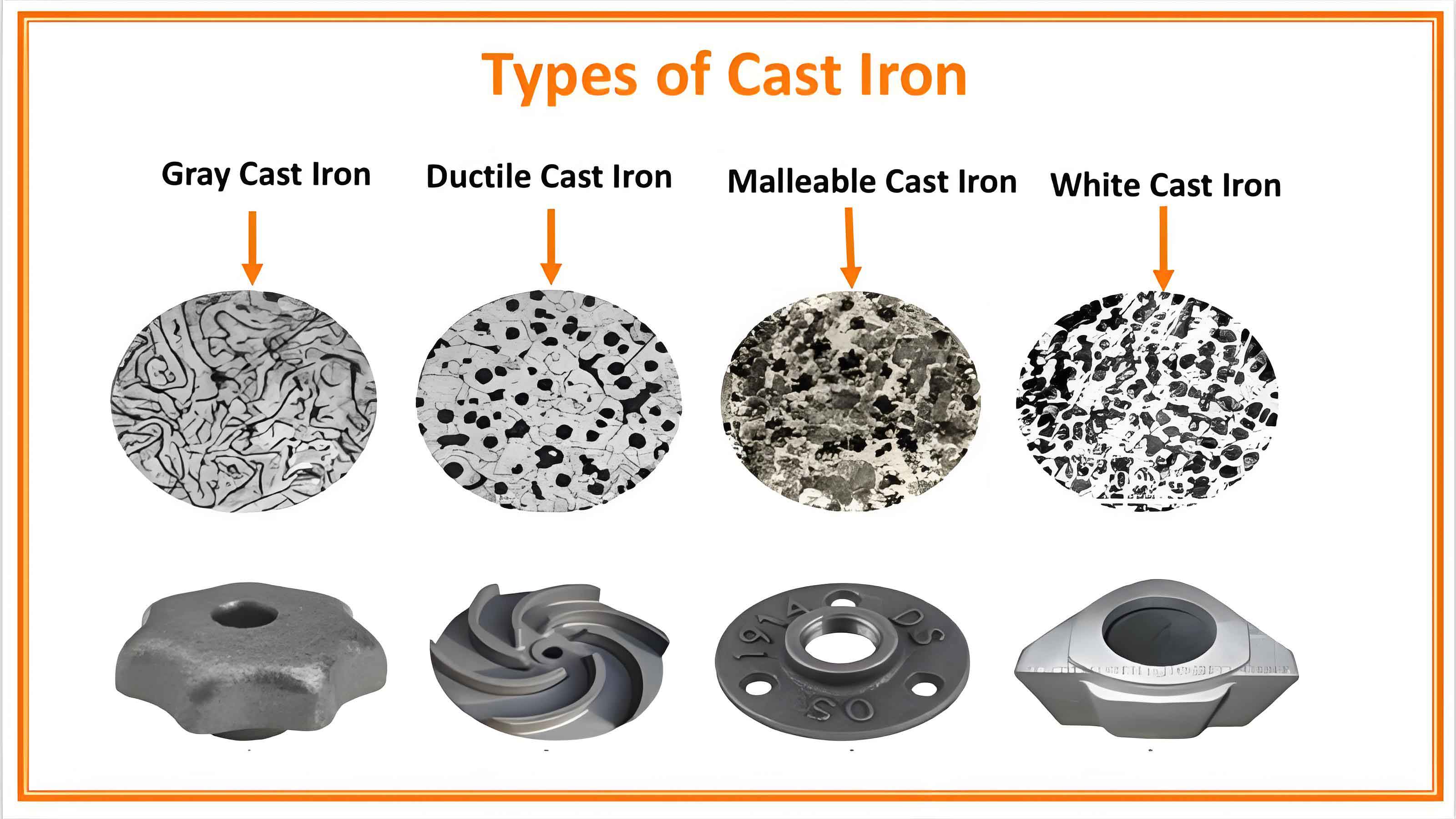

Graphite nodules are formed during the solidification process of ductile cast iron. The addition of magnesium or cerium to the molten iron promotes the formation of spherical graphite nodules rather than flake-like structures found in gray cast iron. This nodule formation enhances the mechanical properties of the cast iron.

Microstructural Characteristics

The microstructure of ductile cast iron typically consists of graphite nodules embedded in a matrix of ferrite, pearlite, or a combination of both. The size, shape, and distribution of these nodules, along with the matrix structure, are critical factors influencing the material’s mechanical properties.

Fracture Mechanics of Ductile Cast Iron

Toughness and Ductility

The presence of graphite nodules significantly enhances the toughness and ductility of ductile cast iron. These nodules act as crack arresters, impeding the propagation of cracks through the material. The nodular shape minimizes stress concentration points, which are common in other forms of cast iron with different graphite morphologies.

Table 1: Mechanical Properties of Ductile Cast Iron

| Property | Value |

|---|---|

| Tensile Strength (MPa) | 400 – 700 |

| Yield Strength (MPa) | 250 – 500 |

| Elongation (%) | 5 – 25 |

| Hardness (HB) | 140 – 300 |

| Impact Toughness (J) | 12 – 20 |

Crack Initiation and Propagation

Graphite nodules influence both the initiation and propagation of cracks in ductile cast iron. During loading, the nodules deform plastically, absorbing energy and delaying the onset of crack initiation. Once a crack is initiated, the nodules interact with the crack tip, reducing the stress intensity factor and slowing down crack propagation.

Stress Distribution

The distribution of graphite nodules affects the stress distribution within the material. A uniform distribution of small, well-formed nodules results in more uniform stress distribution, reducing the likelihood of crack initiation. Conversely, larger or irregularly shaped nodules can act as stress concentrators, potentially leading to premature failure.

Table 2: Influence of Graphite Nodules on Fracture Mechanics

| Nodule Characteristic | Effect on Fracture Mechanics |

|---|---|

| Size | Smaller nodules improve toughness and delay crack initiation |

| Shape | Spherical nodules reduce stress concentration |

| Distribution | Uniform distribution enhances overall toughness |

Experimental Methodology

The study involves analyzing ductile cast iron samples with varying graphite nodule characteristics. Samples are subjected to mechanical testing, including tensile, impact, and fracture toughness tests. Microstructural analysis is performed using optical microscopy and scanning electron microscopy (SEM) to correlate nodule characteristics with fracture behavior.

Results and Discussion

Microstructural Analysis

Microstructural analysis reveals the influence of graphite nodule size, shape, and distribution on the fracture behavior of ductile cast iron.

Table 3: Microstructural Analysis of Graphite Nodules

| Sample | Nodule Size (µm) | Nodule Shape | Nodule Distribution |

|---|---|---|---|

| Sample A | 20 – 30 | Spherical | Uniform |

| Sample B | 30 – 50 | Irregular | Non-uniform |

| Sample C | 10 – 20 | Spherical | Uniform |

| Sample D | 40 – 60 | Irregular | Non-uniform |

Mechanical Testing

Mechanical testing shows that samples with smaller, uniformly distributed spherical nodules exhibit superior toughness and fracture resistance.

Table 4: Mechanical Properties and Fracture Toughness

| Sample | Tensile Strength (MPa) | Impact Toughness (J) | Fracture Toughness (MPa√m) |

|---|---|---|---|

| Sample A | 600 | 18 | 30 |

| Sample B | 550 | 14 | 25 |

| Sample C | 620 | 20 | 32 |

| Sample D | 530 | 12 | 22 |

Discussion

The results indicate that the size, shape, and distribution of graphite nodules are critical factors in determining the fracture mechanics of ductile cast iron. Smaller, spherical nodules that are uniformly distributed enhance the material’s toughness and resistance to crack initiation and propagation. These findings suggest that controlling the formation and distribution of graphite nodules during the casting process is essential for optimizing the performance of ductile cast iron components.

Conclusion

Graphite nodules play a pivotal role in the fracture mechanics of ductile cast iron. Their size, shape, and distribution significantly influence the material’s toughness, crack initiation, and propagation behavior. By optimizing the characteristics of graphite nodules through careful control of the casting process, the performance and reliability of ductile cast iron components can be greatly enhanced. This understanding is crucial for designing and manufacturing high-performance ductile cast iron for various industrial applications.