Nodular cast iron has become a critical material in the automotive industry due to its superior mechanical properties, such as high tensile strength, toughness, and ductility. This article explores the innovative applications of nodular cast iron in modern automotive manufacturing, highlighting its advantages, specific uses, and the technological advancements that enhance its performance.

Introduction

The automotive industry continuously seeks materials that offer a combination of strength, durability, and cost-effectiveness. Nodular cast iron meets these criteria and has seen increased utilization in various automotive components. This article provides an overview of the innovative applications of nodular cast iron in modern automotive manufacturing, demonstrating its importance in enhancing vehicle performance and reliability.

Advantages of Nodular Cast Iron

Nodular cast iron offers several advantages that make it ideal for automotive applications:

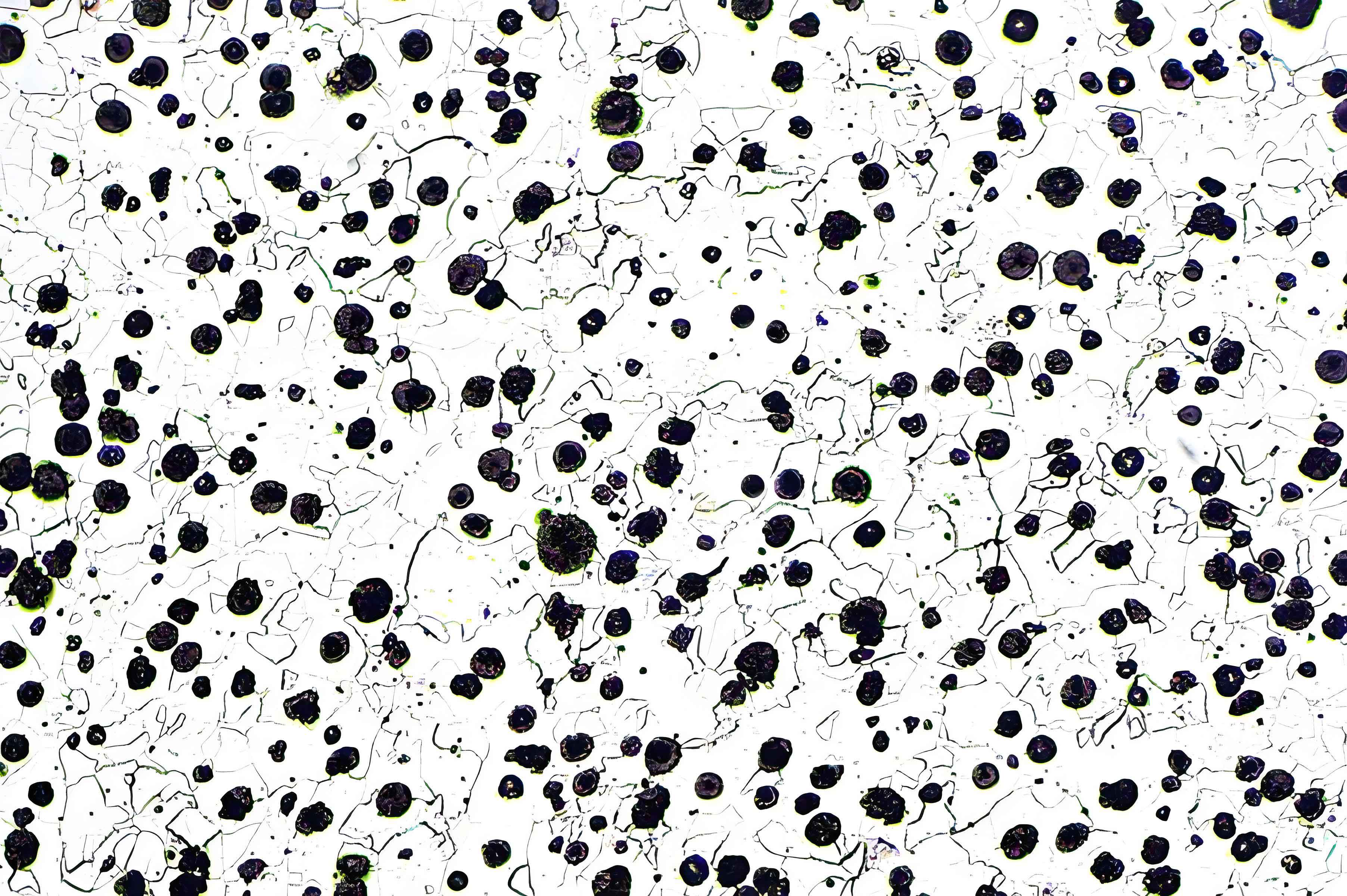

- High Strength and Ductility: The spherical graphite nodules in nodular cast iron enhance its tensile strength and ductility, allowing it to withstand significant mechanical stresses.

- Good Wear Resistance: Its wear resistance makes it suitable for components subjected to friction and abrasion.

- Cost-Effectiveness: Nodular cast iron is relatively inexpensive to produce compared to other high-strength materials.

- Machinability: It can be easily machined into complex shapes, which is essential for manufacturing precision automotive parts.

Table 1: Comparison of Nodular Cast Iron with Other Automotive Materials

| Property | Nodular Cast Iron | Aluminum Alloys | Steel Alloys |

|---|---|---|---|

| Tensile Strength | High | Medium | High |

| Ductility | High | Low to Medium | Medium to High |

| Wear Resistance | High | Low | High |

| Cost | Low | Medium to High | Medium |

| Machinability | Good | Excellent | Good |

| Density (g/cm³) | 6.9 – 7.3 | 2.7 | 7.8 |

Innovative Applications in Automotive Manufacturing

Engine Components

Nodular cast iron is widely used in the production of engine components such as crankshafts, camshafts, and cylinder heads. Its ability to withstand high stresses and temperatures makes it ideal for these critical parts.

Case Study: Crankshafts

- Material: Nodular Cast Iron

- Benefits: Improved fatigue resistance, reduced vibration, and enhanced durability.

- Outcome: Increased engine lifespan and performance.

Suspension Systems

The suspension system of a vehicle is crucial for ensuring a smooth ride and handling. Nodular cast iron’s strength and ductility make it suitable for manufacturing control arms, steering knuckles, and axle housings.

Table 2: Benefits of Nodular Cast Iron in Suspension Components

| Component | Benefits of Nodular Cast Iron |

|---|---|

| Control Arms | High strength-to-weight ratio, durability |

| Steering Knuckles | Enhanced impact resistance, reliability |

| Axle Housings | Superior load-bearing capacity |

Brake Components

Brake discs and drums made from nodular cast iron provide excellent wear resistance and thermal conductivity, ensuring efficient braking performance and longevity.

Differential Housings

Differential housings made from nodular cast iron offer high strength and resistance to fatigue, which is essential for managing the power distribution to the vehicle’s wheels.

Table 3: Key Properties for Differential Housings

| Property | Importance |

|---|---|

| High Tensile Strength | Withstands torque and rotational forces |

| Fatigue Resistance | Prolongs component lifespan |

| Thermal Conductivity | Manages heat generated during operation |

Turbocharger Housings

The high-temperature resistance of nodular cast iron makes it suitable for turbocharger housings, which are exposed to extreme heat and pressure.

Transmission Components

Gears and shafts in transmission systems benefit from the wear resistance and machinability of nodular cast iron, ensuring smooth and efficient power transmission.

Technological Advancements

Recent advancements in material science and manufacturing processes have further enhanced the properties and applications of nodular cast iron in the automotive industry.

Heat Treatment Processes

Heat treatment techniques, such as austempering, have been developed to improve the toughness and wear resistance of nodular cast iron components.

Alloying Additions

The addition of alloying elements such as molybdenum, nickel, and chromium can enhance the mechanical properties and corrosion resistance of nodular cast iron.

Table 4: Effects of Alloying Elements on Nodular Cast Iron

| Alloying Element | Effects |

|---|---|

| Molybdenum | Increases strength and wear resistance |

| Nickel | Enhances toughness and ductility |

| Chromium | Improves corrosion and oxidation resistance |

Advanced Casting Techniques

Innovations in casting techniques, such as vacuum casting and precision molding, allow for the production of complex and high-quality nodular cast iron components with minimal defects.

Computational Modeling

The use of computational modeling and simulation has enabled the optimization of nodular cast iron components, leading to improved design and performance in automotive applications.

Conclusion

Nodular cast iron has proven to be an invaluable material in modern automotive manufacturing, offering a combination of high strength, ductility, and cost-effectiveness. Its innovative applications in engine components, suspension systems, brake components, differential housings, turbocharger housings, and transmission components underscore its versatility and importance. Technological advancements in heat treatment, alloying, casting techniques, and computational modeling continue to enhance its properties, ensuring that nodular cast iron remains a cornerstone in the production of reliable and high-performance automotive components.