Nodular cast iron has revolutionized the manufacturing and functionality of heavy machinery due to its superior mechanical properties, including high strength, excellent ductility, and enhanced fatigue resistance. This article delves into the critical role of nodular cast iron in heavy machinery, exploring its applications, advantages, and the technological advancements that further improve its performance.

Introduction

Heavy machinery used in industries such as construction, mining, and manufacturing requires materials that can withstand extreme mechanical stresses and harsh environmental conditions. Nodular cast iron, with its unique combination of strength, toughness, and versatility, has become an indispensable material in the production of various heavy machinery components. This article examines how nodular cast iron contributes to the efficiency, durability, and performance of heavy machinery.

Advantages of Nodular Cast Iron

Nodular cast iron offers several advantages that make it suitable for use in heavy machinery:

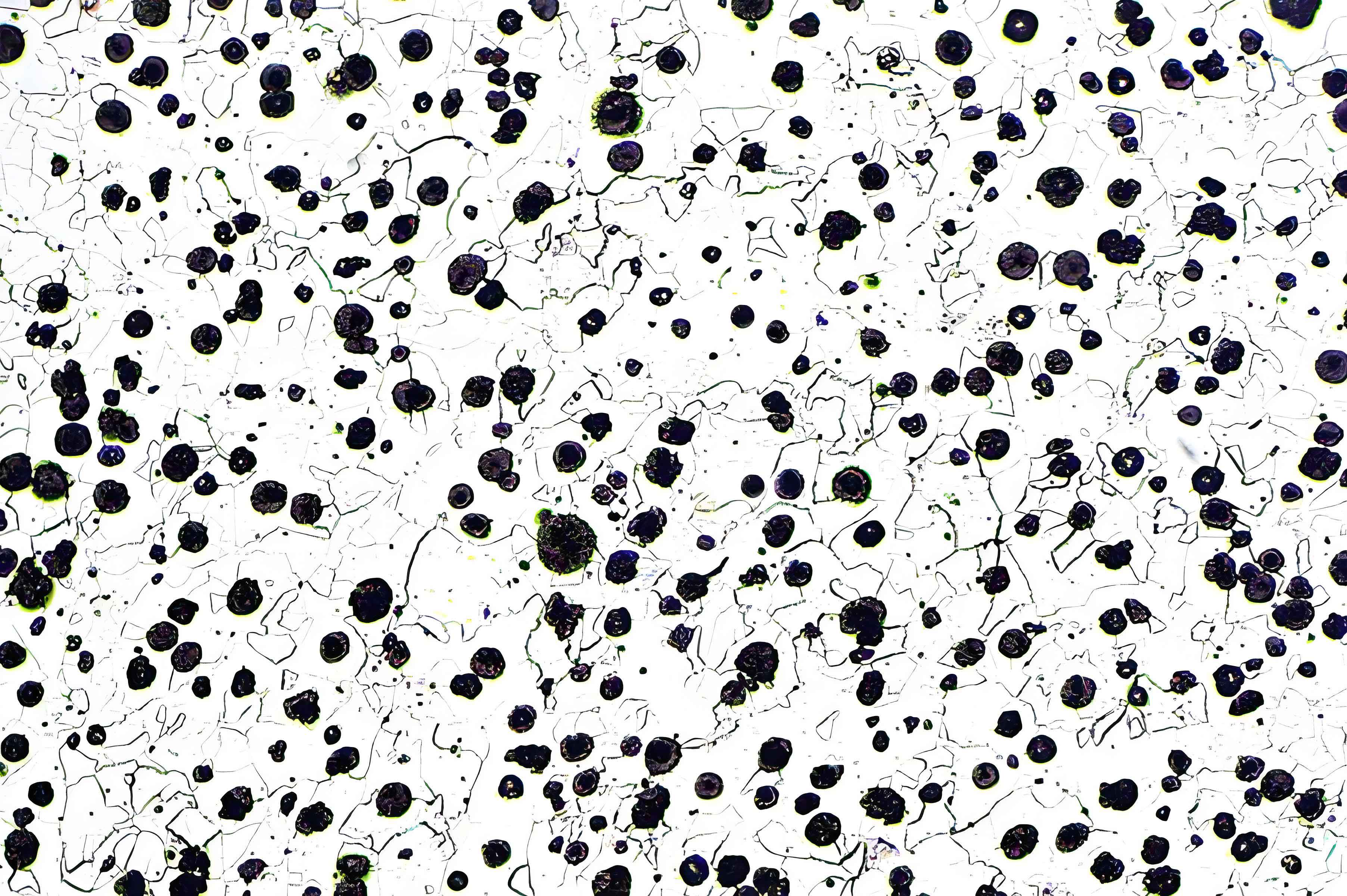

- High Tensile Strength and Ductility: The spherical graphite nodules in nodular cast iron enhance its tensile strength and ductility, allowing it to absorb and dissipate stresses more effectively.

- Excellent Wear Resistance: Its ability to resist wear makes it ideal for components that experience high levels of friction and abrasion.

- Fatigue Resistance: Nodular cast iron’s microstructure provides superior fatigue resistance, making it durable under cyclic loading conditions.

- Machinability: It can be easily machined into complex shapes, essential for manufacturing precision parts.

- Cost-Effectiveness: Compared to other high-strength materials, nodular cast iron is relatively inexpensive to produce.

Table 1: Comparison of Nodular Cast Iron with Other Materials Used in Heavy Machinery

| Property | Nodular Cast Iron | Carbon Steel | Cast Steel |

|---|---|---|---|

| Tensile Strength | High | Medium to High | High |

| Ductility | High | Low to Medium | Medium |

| Wear Resistance | High | Medium | Medium |

| Fatigue Resistance | Excellent | Good | Good |

| Cost | Low | Medium | High |

| Machinability | Good | Fair | Fair |

| Density (g/cm³) | 6.9 – 7.3 | 7.85 | 7.85 |

Applications in Heavy Machinery

Engine Components

Nodular cast iron is widely used in the production of engine components such as crankshafts, camshafts, and cylinder liners. These parts must endure high stresses and temperatures, and nodular cast iron provides the necessary strength and durability.

Case Study: Crankshafts

- Material: Nodular Cast Iron

- Benefits: Enhanced fatigue resistance, improved vibration damping, and increased lifespan.

- Outcome: Reliable performance in heavy-duty engines.

Gear Systems

Gear systems in heavy machinery, such as those in excavators, bulldozers, and mining equipment, require materials that can withstand high loads and resist wear. Nodular cast iron is ideal for manufacturing gears, shafts, and bearings due to its excellent wear resistance and fatigue strength.

Table 2: Benefits of Nodular Cast Iron in Gear Systems

| Component | Benefits of Nodular Cast Iron |

|---|---|

| Gears | High strength, excellent wear resistance |

| Shafts | Superior fatigue resistance, durability |

| Bearings | Reduced friction, extended service life |

Hydraulic Components

Hydraulic components such as cylinders, valves, and pumps benefit from the strength and machinability of nodular cast iron. These components need to withstand high pressures and repeated stress cycles.

Structural Components

The structural integrity of heavy machinery is often maintained by using nodular cast iron for parts such as frames, housings, and brackets. Its high strength-to-weight ratio and durability make it ideal for these applications.

Table 3: Structural Components and Their Requirements

| Component | Requirements |

|---|---|

| Frames | High strength, impact resistance |

| Housings | Durability, fatigue resistance |

| Brackets | High load-bearing capacity, machinability |

Brake Components

Brake discs and drums made from nodular cast iron provide excellent thermal conductivity and wear resistance, ensuring reliable braking performance in heavy machinery.

Technological Advancements

Recent technological advancements have further improved the properties and applications of nodular cast iron in heavy machinery.

Alloying and Heat Treatment

The addition of alloying elements such as nickel, chromium, and molybdenum, combined with advanced heat treatment processes, enhances the mechanical properties and corrosion resistance of nodular cast iron.

Table 4: Effects of Alloying Elements on Nodular Cast Iron

| Alloying Element | Effects |

|---|---|

| Nickel | Increases toughness and ductility |

| Chromium | Enhances corrosion and oxidation resistance |

| Molybdenum | Improves strength and wear resistance |

Advanced Casting Techniques

Innovations in casting techniques, such as precision molding and vacuum casting, have enabled the production of high-quality nodular cast iron components with complex geometries and minimal defects.

Surface Treatments

Surface treatments such as carburizing, nitriding, and coatings can significantly enhance the wear resistance and fatigue life of nodular cast iron components.

Computational Modeling

The use of computational modeling and simulation has allowed for the optimization of nodular cast iron components, leading to improved design and performance in heavy machinery.

Case Studies

Construction Machinery

In the construction industry, nodular cast iron is used in the production of components for excavators, loaders, and cranes. Its high strength and durability ensure reliable operation under harsh working conditions.

Mining Equipment

Mining equipment such as drills, crushers, and conveyors rely on nodular cast iron for critical components. The material’s wear resistance and toughness are essential for withstanding the abrasive and high-impact conditions found in mining environments.

Agricultural Machinery

Agricultural machinery, including tractors and harvesters, benefits from the use of nodular cast iron in engine parts, gear systems, and structural components. Its properties ensure long-lasting performance and reduced maintenance requirements.

Conclusion

Nodular cast iron plays a vital role in the manufacturing and operation of heavy machinery across various industries. Its combination of high strength, ductility, wear resistance, and cost-effectiveness makes it an ideal material for critical components that must endure extreme mechanical stresses and harsh environments. Technological advancements in alloying, casting, and surface treatments continue to enhance the performance of nodular cast iron, ensuring its ongoing relevance and utility in modern heavy machinery.