High-performance steel casting has revolutionized the construction and infrastructure sectors by providing materials that are not only stronger but also more durable and versatile than traditional steel. This article delves into the benefits, applications, current trends, and future prospects of using high-performance steel casting in construction and infrastructure. Detailed tables and lists are included to enhance comprehension.

Introduction

High-performance steel casting is engineered to meet the demanding requirements of modern construction and infrastructure projects. These castings are produced using advanced alloys and state-of-the-art manufacturing processes that impart superior mechanical properties, including increased strength, durability, and resistance to environmental factors. The use of high-performance steel casting is pivotal in creating robust, long-lasting structures that can withstand the rigors of time and harsh conditions.

Benefits of High-Performance Steel Casting

- Superior Strength and Durability:

- High-performance steel casting offer exceptional tensile and compressive strength, which are crucial for supporting heavy loads and ensuring structural integrity.

- Enhanced Corrosion Resistance:

- The advanced alloy compositions provide excellent resistance to corrosion, making these steel casting ideal for structures exposed to harsh environmental conditions.

- Design Flexibility:

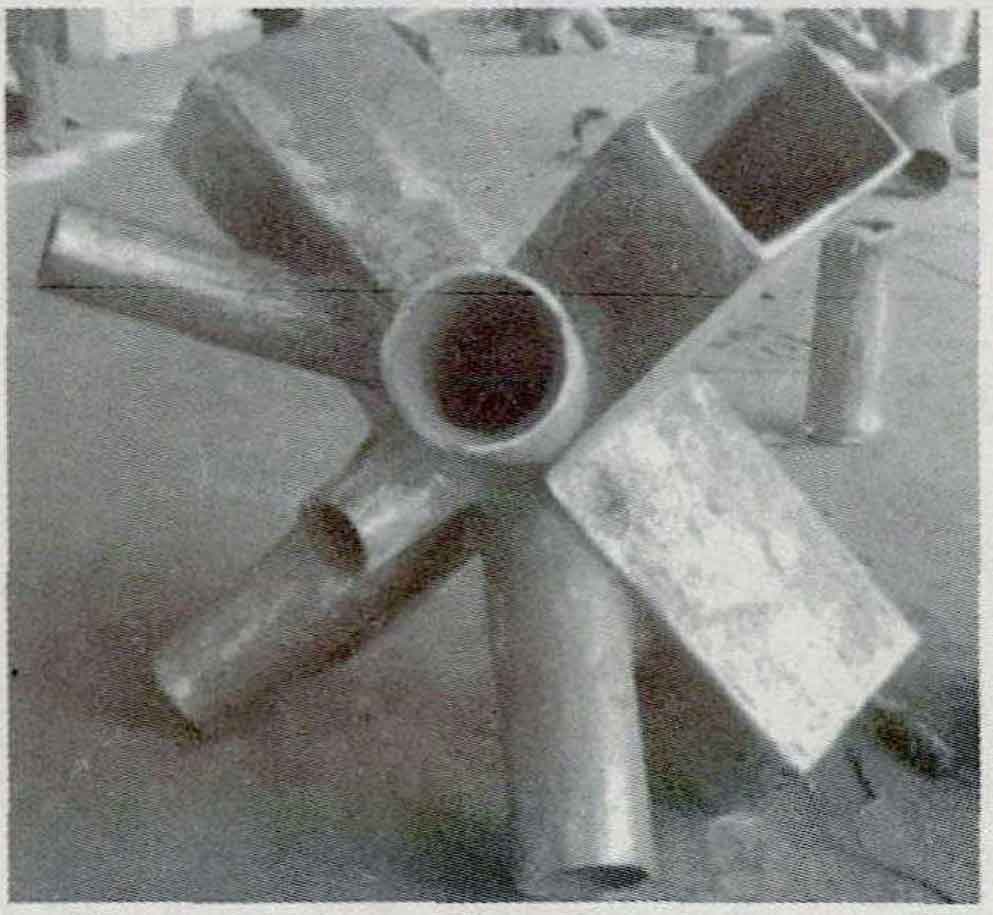

- The steel casting process allows for the creation of complex shapes and intricate designs that are difficult to achieve with traditional steel fabrication methods.

- Cost-Effectiveness:

- Although initially more expensive, the longevity and reduced maintenance needs of high-performance steel casting result in lower lifecycle costs.

- Sustainability:

- The use of durable materials reduces the need for frequent replacements, contributing to more sustainable construction practices.

Table: Benefits of High-Performance Steel Casting

| Benefit | Description | Impact on Construction and Infrastructure |

|---|---|---|

| Superior Strength | Exceptional tensile and compressive strength | Increased structural integrity and load-bearing capacity |

| Durability | Long-lasting performance under various conditions | Reduced maintenance and replacement costs |

| Corrosion Resistance | Excellent resistance to corrosion and environmental degradation | Extended lifespan of exposed components |

| Design Flexibility | Ability to create complex shapes and intricate designs | Greater architectural and engineering possibilities |

| Cost-Effectiveness | Lower lifecycle costs due to reduced maintenance needs | Long-term financial savings |

| Sustainability | Reduced need for frequent replacements | More sustainable construction practices |

Applications of High-Performance Steel Casting

- Bridges:

- Components: Supports, beams, joints, and trusses.

- Benefits: High load-bearing capacity and resistance to environmental degradation.

- Buildings:

- Components: Structural frameworks, reinforcing bars, load-bearing walls, and facades.

- Benefits: Enhanced safety, stability, and architectural flexibility.

- Transportation Infrastructure:

- Components: Railway tracks, highway bridges, tunnels, and airport structures.

- Benefits: Improved reliability and longevity under heavy traffic and dynamic loads.

- Utilities and Public Works:

- Components: Water treatment plants, sewage systems, power generation facilities.

- Benefits: Durability and resistance to harsh environmental conditions.

- Industrial Facilities:

- Components: Heavy machinery bases, crane components, and industrial buildings.

- Benefits: Robust performance and extended service life in demanding industrial environments.

List: Key Applications of High-Performance Steel Casting

- Bridges:

- Supports

- Beams

- Joints

- Trusses

- Buildings:

- Structural frameworks

- Reinforcing bars

- Load-bearing walls

- Facades

- Transportation Infrastructure:

- Railway tracks

- Highway bridges

- Tunnels

- Airport structures

- Utilities and Public Works:

- Water treatment plants

- Sewage systems

- Power generation facilities

- Industrial Facilities:

- Heavy machinery bases

- Crane components

- Industrial buildings

Current Trends in High-Performance Steel Casting

- Advanced Casting Techniques:

- Adoption of precision casting, investment casting, and 3D printing to improve the accuracy and quality of steel casting.

- Integration of Smart Technologies:

- Incorporating sensors and IoT devices into steel cast components for real-time monitoring and predictive maintenance.

- Sustainable Manufacturing Processes:

- Implementing eco-friendly production methods, such as recycling scrap steel and reducing energy consumption.

- Development of New Alloys:

- Continuous research into new steel alloys that offer enhanced properties, such as higher strength-to-weight ratios and improved corrosion resistance.

- Collaboration with Digital Technologies:

- Utilizing digital twins and simulation software to optimize the design and performance of steel castings before production.

Table: Current Trends in High-Performance Steel Casting

| Trend | Description | Expected Benefits |

|---|---|---|

| Advanced Casting Techniques | Use of precision casting, investment casting, and 3D printing | Improved accuracy and quality of castings |

| Integration of Smart Technologies | Incorporation of sensors and IoT for real-time monitoring | Enhanced maintenance and lifecycle management |

| Sustainable Manufacturing Processes | Eco-friendly production methods, such as recycling and energy reduction | Lower environmental impact |

| Development of New Alloys | Research into alloys with superior properties | Higher performance and durability |

| Collaboration with Digital Technologies | Use of digital twins and simulation software | Optimized design and performance |

Future Prospects for High-Performance Steel Casting

- Nanotechnology:

- Application of nanotechnology to develop steel alloys with superior mechanical properties and self-healing capabilities.

- Automated and Digitalized Production:

- Increased use of automation and digitalization in the steel casting process to improve efficiency and consistency.

- Integration with Renewable Energy Projects:

- High-performance steel casting will be critical in the construction of renewable energy infrastructure, such as wind turbines and solar panel supports.

- Global Infrastructure Development:

- Growing investments in infrastructure worldwide will drive demand for high-performance steel casting, fostering innovation and advancement in the field.

- Enhanced Safety Standards:

- Implementation of stricter safety standards and regulations will necessitate the use of high-performance materials to ensure compliance and safety.

List: Future Prospects for High-Performance Steel Casting

- Nanotechnology:

- Development of alloys with superior mechanical properties

- Self-healing capabilities

- Automated and Digitalized Production:

- Improved efficiency and consistency in the steel casting process

- Integration with Renewable Energy Projects:

- Construction of wind turbines

- Solar panel supports

- Global Infrastructure Development:

- Increased demand driving innovation

- Advancements in steel casting technology

- Enhanced Safety Standards:

- Stricter safety regulations

- Use of high-performance materials

Conclusion

High-performance steel casting is transforming the construction and infrastructure industries by providing materials with unparalleled strength, durability, and versatility. The benefits of using these advanced castings include increased structural integrity, reduced maintenance costs, and greater design flexibility. Current trends, such as advanced casting techniques, smart technologies, and sustainable manufacturing processes, are paving the way for future innovations. As the demand for robust and reliable infrastructure continues to grow, high-performance steel casting will play an increasingly vital role in meeting these challenges, ensuring a resilient and sustainable future for construction and infrastructure projects worldwide.