Introduction

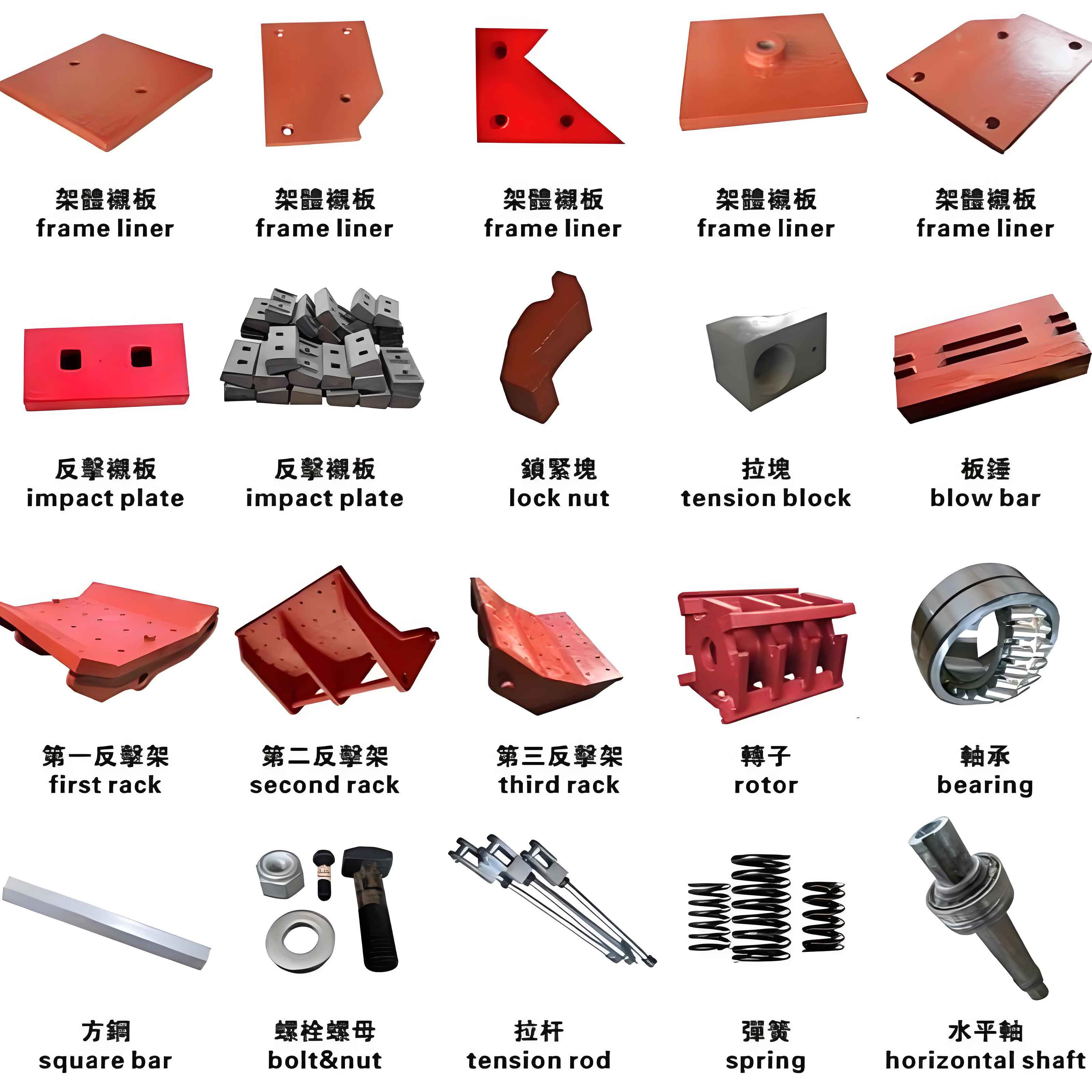

Blow bar is critical components of impact crushers used in quarrying, mining, and various other industrial applications. Their primary function is to impact and crush materials, which subjects them to significant wear and tear. To ensure blow bar can withstand the rigorous demands of their operation, enhancing their toughness is essential. Heat treatment techniques play a crucial role in improving the toughness and overall performance of blow bar. This article explores various heat treatment methods and their impact on the properties of blow bar.

Importance of Toughness in Blow Bar

Toughness is the ability of a material to absorb energy and deform plastically before fracturing. For blow bar, high toughness is crucial to resist the impact forces and abrasive conditions they encounter during operation. Enhancing toughness reduces the likelihood of blow bar breakage and extends the service life of the impact crusher.

Heat Treatment Techniques

Several heat treatment techniques can be applied to blow bar to enhance their toughness. Each method involves controlled heating and cooling processes that alter the microstructure of the material, resulting in improved mechanical properties.

1. Annealing

Annealing is a heat treatment process that involves heating the blow bar to a specific temperature, holding it at that temperature for a period, and then slowly cooling it. This process relieves internal stresses, refines the grain structure, and improves ductility and toughness.

Steps in Annealing:

- Heating: The blow bar is heated to a temperature above its recrystallization temperature.

- Soaking: The blow bar is held at this temperature for a specific period to allow for grain growth and stress relief.

- Cooling: The blow bar is slowly cooled to room temperature, typically in a furnace.

Benefits of Annealing:

- Enhanced toughness and ductility

- Reduced internal stresses

- Improved machinability

Applications:

- Used for blow bar made of high manganese steel and other alloy steels.

2. Quenching and Tempering

Quenching and tempering is a two-step heat treatment process that significantly enhances the toughness of blow bar. Quenching involves rapid cooling from a high temperature, while tempering involves reheating to a lower temperature followed by controlled cooling.

Steps in Quenching and Tempering:

- Quenching: The blow bar is heated to a high temperature and then rapidly cooled in a quenching medium (oil, water, or air).

- Tempering: The quenched blow bar is reheated to a temperature below its critical point, held at that temperature, and then cooled.

Benefits of Quenching and Tempering:

- Increased hardness and strength

- Enhanced toughness and impact resistance

- Improved wear resistance

Applications:

- Ideal for blow bar used in extremely abrasive environments.

3. Austempering

Austempering is a heat treatment process that improves the toughness and wear resistance of blow bar. It involves heating the blow bar to a temperature where austenite forms, followed by rapid cooling to a temperature where bainite forms and holding it until transformation is complete.

Steps in Austempering:

- Heating: The blow bar is heated to the austenitizing temperature.

- Rapid Cooling: The blow bar is rapidly cooled to a bainitic transformation temperature and held until the transformation to bainite is complete.

- Cooling: The blow bar is cooled to room temperature.

Benefits of Austempering:

- Improved toughness and ductility

- Enhanced wear resistance

- Reduced risk of distortion and cracking

Applications:

- Suitable for blow bar in high-impact and wear-intensive applications.

Comparison of Heat Treatment Techniques

| Technique | Process | Benefits | Applications |

|---|---|---|---|

| Annealing | Heating, soaking, slow cooling | Enhanced toughness, reduced stresses | High manganese steel blow bars |

| Quenching and Tempering | Rapid cooling followed by reheating and controlled cooling | Increased hardness, enhanced toughness | Extremely abrasive environments |

| Austempering | Heating, rapid cooling, holding at bainitic temperature | Improved toughness, reduced distortion | High-impact and wear-intensive applications |

Factors Affecting Heat Treatment Outcomes

Several factors influence the effectiveness of heat treatment techniques in enhancing the toughness of blow bar:

- Material Composition:

- Different alloys respond differently to heat treatment processes.

- The presence of elements like manganese, chromium, and molybdenum can significantly affect the outcome.

- Temperature Control:

- Precise control of heating and cooling temperatures is crucial for achieving desired properties.

- Variations in temperature can lead to inconsistent results and reduced toughness.

- Holding Time:

- The duration for which the blow bar is held at specific temperatures impacts the microstructure transformation.

- Adequate holding time ensures complete transformation and uniform properties.

- Cooling Rate:

- The rate at which the blow bar is cooled affects the formation of microstructures like martensite, bainite, and pearlite.

- Controlled cooling rates are essential to prevent cracking and distortion.

Common Issues and Solutions

Despite the benefits of heat treatment, several issues can arise during the process. Identifying and addressing these issues is crucial for ensuring optimal blow bar performance.

Common Issues:

- Cracking:

- Rapid cooling or improper handling can cause blow bar to crack.

- Solution: Use controlled cooling rates and handle blow bar with care during the heat treatment process.

- Distortion:

- Uneven cooling or improper fixturing can lead to distortion of blow bar.

- Solution: Ensure uniform cooling and use appropriate fixturing techniques to maintain the shape of blow bar.

- Inconsistent Properties:

- Variations in temperature or holding time can result in inconsistent properties.

- Solution: Maintain precise control over heat treatment parameters and ensure consistent process conditions.

Solutions for Common Issues:

| Issue | Cause | Solution |

|---|---|---|

| Cracking | Rapid cooling, improper handling | Use controlled cooling rates, careful handling |

| Distortion | Uneven cooling, improper fixturing | Ensure uniform cooling, appropriate fixturing |

| Inconsistent Properties | Variations in temperature or holding time | Precise control of heat treatment parameters |

Conclusion

Heat treatment techniques are essential for enhancing the toughness and overall performance of blow bar used in impact crushers. Annealing, quenching and tempering, and austempering are effective methods for improving the mechanical properties of blow bar, ensuring they can withstand the harsh conditions of quarry and mining applications. By understanding the processes, benefits, and applications of each technique, as well as addressing common issues, operators can optimize the performance and longevity of their blow bar. Proper heat treatment not only extends the service life of blow bar but also contributes to the efficiency and cost-effectiveness of crushing operations.