Abstract

This paper presents an optimization of the sand casting process for gray iron upper rotary disc castings using numerical simulation techniques. The three-dimensional model of the gray iron upper rotary disc was created using SolidWorks software. Based on the analysis of the casting’s structure, shape, size, and application, an initial casting process scheme was designed. The casting process was then simulated using ProCAST software to analyze the temperature field, filling, and solidification processes. Defects such as shrinkage porosity and shrinkage cavities were predicted and analyzed. Through the addition of risers and optimization of the pouring system, the casting process was improved to effectively control defects. The optimized casting process simulation results show that shrinkage porosity and shrinkage cavities were significantly reduced, enhancing the overall quality of the castings.

Introduction

The upper rotary disc, made of gray iron (HT300), is a critical transmission component widely used in engineering machinery such as railway transportation and machine tools. Its primary functions include supporting the weight of the machine and guiding the tool holder. The disc must withstand both static and dynamic loads, necessitating high strength, stability, and wear resistance. Due to its complex internal structure, casting defects such as shrinkage porosity and shrinkage cavities often occur in thick sections, compromising casting quality.

Computer-aided numerical simulation plays a vital role in optimizing casting processes, predicting casting defects, and improving casting quality. In this study, ProCAST software was employed to simulate the sand casting process of the gray iron upper rotary disc, aiming to minimize casting defects and enhance casting performance.

Materials and Methods

2.1 Casting Design and Materials

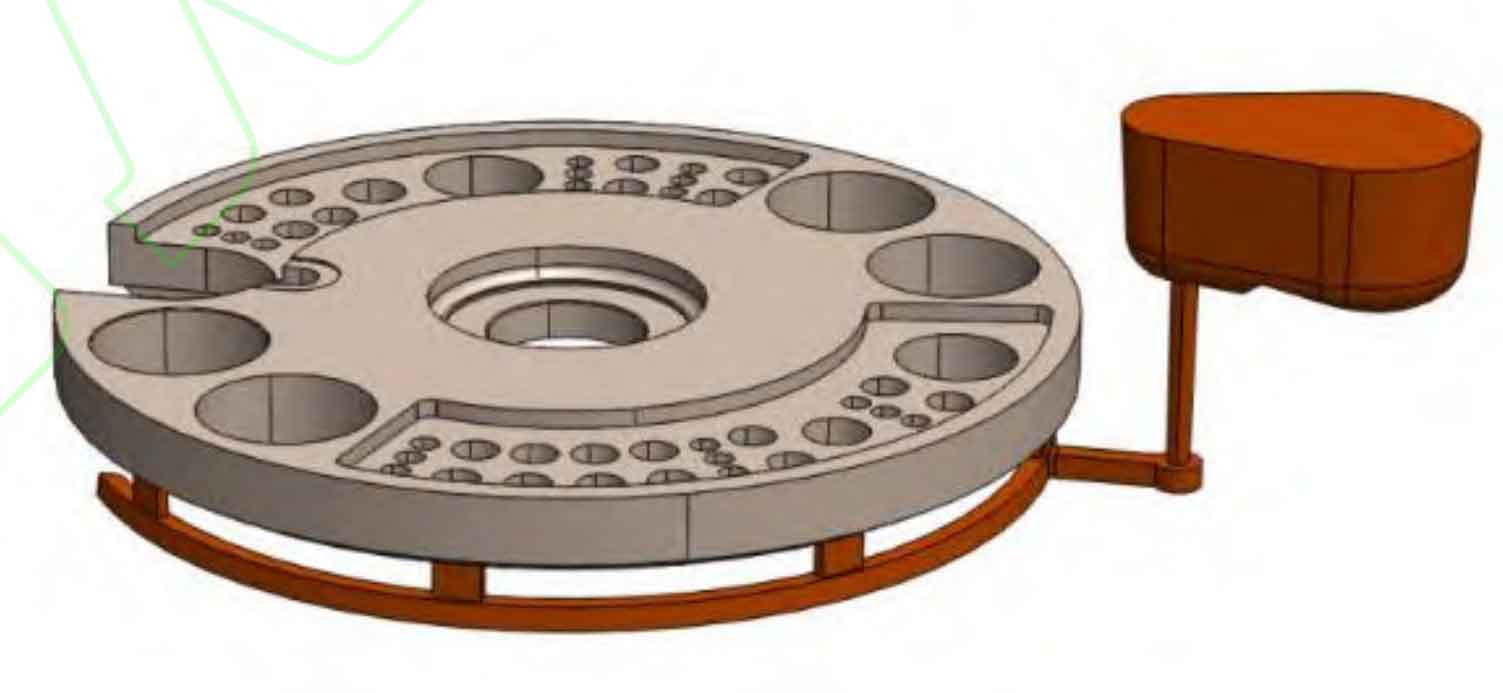

The upper rotary disc has a complex structure with multiple holes and grooves, making it prone to casting defects. The casting material used is gray iron HT300, which has high strength and wear resistance. Its chemical composition is shown in Table 1.

Table 1: Chemical Composition of Gray Iron HT300 (wt.%)

| Material | C | Si | Mn | P | S |

|---|---|---|---|---|---|

| HT300 | 2.80-3.10 | 1.10-1.40 | 1.00-1.20 | <0.15 | ≤0.12 |

The 3D model of the upper rotary disc was created using SolidWorks. The outer dimensions are 1281 mm × 1269.7 mm × 101 mm, with an estimated weight of 502.41 kg. The maximum wall thickness is 113 mm, while the minimum is 15 mm.

2.2 Initial Casting Process Design

Based on the structural characteristics and casting principles, a bottom gating system was chosen due to its ability to provide a fast and uniform filling process, reducing the risk of splashing, turbulence, and misruns. The pouring system comprised one sprue, two runners, and seven ingates, with section ratios of 1.15:1.1:1. The pouring time was calculated to be 47 seconds. The sand casting process utilized furan resin sand for the mold and core, providing excellent thermal stability and casting performance.

2.3 Numerical Simulation Setup

The numerical simulation was performed using ProCAST software, focusing on the filling and solidification processes. The initial conditions were set as follows:

- Pouring temperature: 1370°C

- Pouring time: 47 seconds

- Heat exchange coefficients:

- Metal to sand: 500 W/(m²·K)

- Sand to chill: 500 W/(m²·K)

- Metal to chill: 2000 W/(m²·K)

The casting and pouring system were meshed into 25,636 2D elements and 311,860 3D elements.

Results and Discussion

3.1 Filling Process Analysis

The filling process simulation showed a smooth and steady metal flow from the sprue to the ingates, filling the mold cavity uniformly. the filling process at various stages, demonstrating the metal’s progression through the mold.

3.2 Initial Solidification Defects

Without the addition of risers, the simulation predicted significant shrinkage porosity and cavities in the thick sections of the upper rotary disc, particularly in the top, base, and center regions . These defects were attributed to slow cooling rates in these areas, resulting in isolated liquid regions.

3.3 Casting Process Optimization

To mitigate these defects, the casting process was optimized by incorporating risers and modifying the pouring system. Five top-neck risers and five blind risers were added, detailed in Tables 2 and 3. The pouring system was revised to a top gating configuration with one sprue, one runner, and four ingates.

Table 2: Dimensions of Top-Neck Risers (mm)

| Quantity | R | D | d | R | H |

|---|---|---|---|---|---|

| 5 | 80 | 90 | 30 | 0 | 300 |

Table 3: Dimensions of Blind Risers (mm)

| Quantity | d | h |

|---|---|---|

| 5 | 80 | 180 |

3.4 Optimized Filling and Solidification Processes

The optimized casting process showed improved filling characteristics, with no cold shuts or misruns. The solidification process demonstrated a controlled sequence, with the final solidification occurring within the risers.

3.5 Optimized Solidification Defects

The simulation after optimization revealed a significant reduction in defects, with most shrinkage porosity and cavities shifted to the risers. This allowed for easy removal during post-processing, enhancing the quality of the final casting.

Conclusion

This study optimized the sand casting process for gray iron upper rotary disc castings through numerical simulation using ProCAST software. The initial casting process design was evaluated, and significant defects were predicted in thick sections. By incorporating risers and modifying the pouring system, the optimized process successfully reduced casting defects, enhancing casting quality. The results demonstrate the effectiveness of numerical simulation in predicting and mitigating casting defects, reducing trial and error, and improving production efficiency.