1. Introduction

The crankshaft is a crucial part of the automobile engine, responsible for power output. This article focuses on the wet sand casting process of automotive crankshafts, analyzing the casting process, defects, and control methods to improve casting quality and efficiency.

| Main Points | Details |

|---|---|

| Significance of Crankshaft | Key component for power output in automotive engines, affected by various factors |

| Research Focus | Wet sand casting process, defect analysis, and control strategies |

2. Materials for Automotive Crankshafts

The choice of material for the crankshaft is crucial, considering both mechanical properties and cost.

| Material | Properties | Application in Crankshaft |

|---|---|---|

| Ductile Iron (QT900 – 2) | Good mechanical properties, economic, high resistance to torsion and bending, excellent impact resistance | Widely used in automotive crankshaft production |

3. Wet Sand Casting Process for Ductile Iron Crankshafts

The wet sand casting process for ductile iron crankshafts mainly includes sand mold preparation and pouring.

| Process Steps | Details |

|---|---|

| Sand Mold Preparation | Composition: 5% new sand and the rest old sand. Aim: To create a suitable mold for casting the crankshaft |

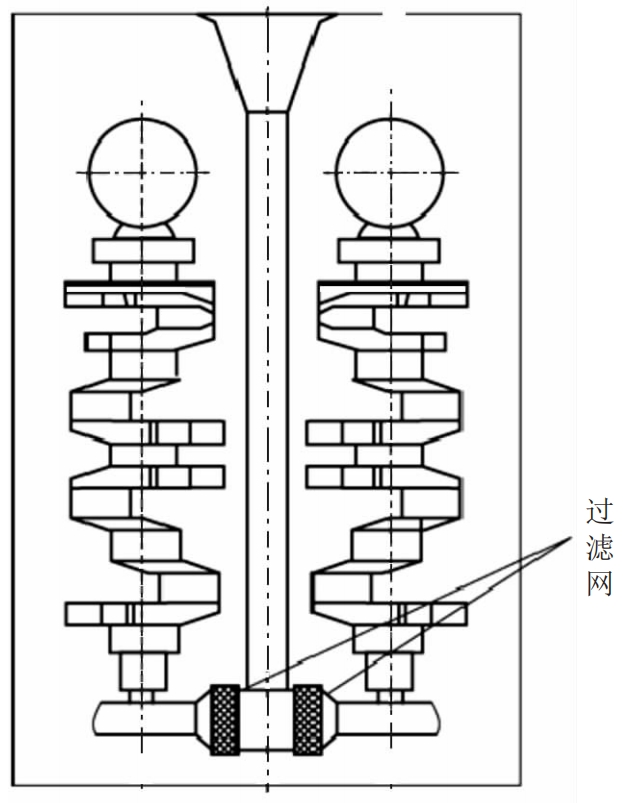

| Pouring Process | Scheme: Sequential solidification (as shown in Fig. 1). Benefit: Suitable for mass production and effective defect control |

4. Defects and Control in Wet Sand Casting of Ductile Iron Crankshafts

Various defects can occur during the casting process, and effective control measures are essential.

| Defect Type | Cause | Control Measures |

|---|---|---|

| Sand Inclusion | Factors like spheroidizing agent and sand. Impact: Complicates post – casting cleaning. Solutions: Add a filter at the pouring end; control sand quality in secondary pouring | |

| Porosity | Nitrogen bubbles trapped during solidification. Effect: Reduces mechanical strength. Prevention: Use low – nitrogen raw materials; add vents at thick – walled parts | |

| Shrinkage and Porosity | Caused by heat transfer in the sand mold. Solution: Place chills outside the hot spot; improve casting process parameters |

5. Conclusion

Wet sand casting of ductile iron crankshafts simplifies production, reduces costs, and enables effective defect control.

| Advantages | Details |

|---|---|

| Process Simplification | Reduces production steps compared to traditional methods |

| Cost Reduction | Lowers production costs |

| Defect Control | Allows for better control and elimination of casting defects |

In summary, the wet sand casting process for automotive crankshafts offers a viable solution for efficient and high – quality production.