Abstract

The quality control of key steel castings for electric multiple unit (EMU) trains. It introduces the technical specifications, surface quality requirements, and internal quality standards of these castings. By examining the prevention and control processes of various defects, such as excessive magnetic mark defects, slag porosity, and invasive porosity, the paper elaborates on the process measures employed to ensure the castings meet the stringent quality demands of high-speed railway applications.

1. Introduction

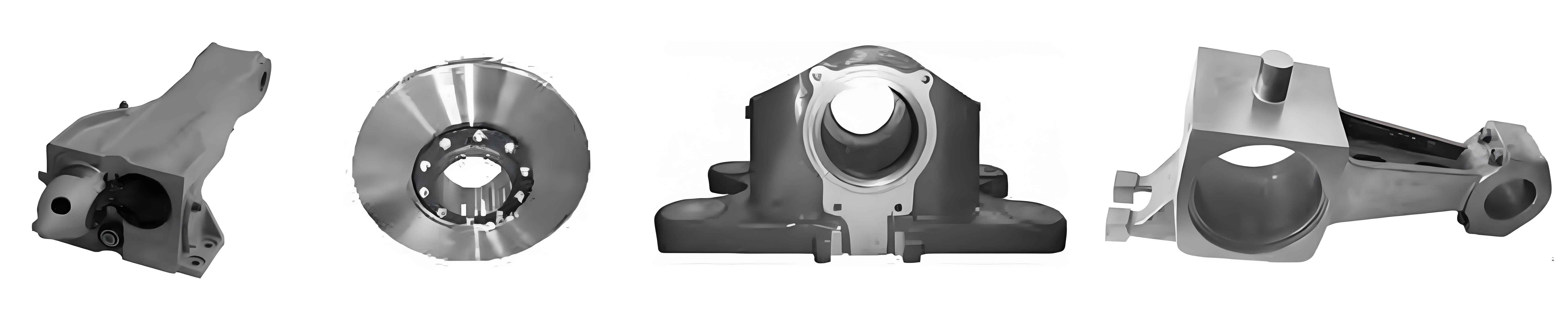

With the rapid development of high-speed railway transportation, the quality requirements for components of high-speed EMUs, particularly key steel castings, have been escalating. These castings, including coupler buffers, brake discs, mounting brackets, and axle boxes, play crucial roles in the safe and efficient operation of EMUs. Ensuring the quality of these castings is paramount to the overall safety and reliability of the trains. This paper aims to provide a comprehensive overview of the quality control measures for key steel castings for EMUs.

2. Technical Requirements for Key Steel Castings

2.1 Material Specifications

The material specifications for key steel castings are crucial as they directly relate to the overall performance of the castings. For instance, brake discs are subjected to significant thermal stress during braking, and their ability to resist thermal shock and maintain high-temperature stability depends on the material properties. These properties are not only influenced by the chemical composition but also by the gas content in the steel, such as oxygen, hydrogen, and nitrogen. Table 1 summarizes the material specifications for key steel castings.

| Material Specification | Requirement |

|---|---|

| Oxygen Content | ≤0.010% |

| Hydrogen Content | ≤0.00005% |

| Nitrogen Content | ≤0.015% |

| Tensile Strength | ≥1050 MPa |

| Elongation After Fracture | ≥8% |

| Non-metallic Inclusions (Type II & IV) | ≤ Grade 1 |

2.2 Surface Quality Requirements

The surface quality of key steel castings for EMUs is equally important. It not only enhances the aesthetic appeal of the product but also contributes to its corrosion and fatigue resistance, thereby prolonging the service life of the casting. The surface quality requirements are stringent, particularly for castings that undergo fatigue loading, such as axle boxes. Defects such as porosity and cracks must be minimized, and specific criteria for defect size and distribution are outlined in Table 2.

| Defect Type | Maximum Diameter | Maximum Depth | Maximum Number per 100 cm² | Minimum Distance from Edge/Hole | Minimum Spacing Between Defects |

|---|---|---|---|---|---|

| Non-crack Defects | Φ1.5 mm | 2 mm | 3 | 10 mm | 20 mm |

Moreover, certain key steel castings do not allow any form of welding repairs, which further emphasizes the need for high quality stability.

2.3 Internal Quality Requirements

The internal quality of key steel castings directly relates to the operational safety of EMUs. Defects such as porosity and shrinkage are closely monitored through radiographic and ultrasonic testing. For instance, axle box castings require radiographic testing with defect levels not exceeding ASTM E446 Class A, B, and C, Grade 2, with no Class D, E, F, or G defects allowed. Similarly, brake discs must undergo ultrasonic testing to ensure no porosity defects within specific thickness ranges from the friction surface.

3. Quality Assurance Measures for Key Steel Castings

3.1 Steel Liquid Quality Control

The quality of steel liquid is crucial for producing defect-free castings. Two significant challenges in steel liquid melting are inadequate final deoxidization and insufficient purity. The total oxygen content in the steel liquid is an indicator of its quality, influencing the number, size, shape, and distribution of non-metallic oxide inclusions. To address these challenges, several measures are employed:

- Raw Material Selection: High-quality low-phosphorus and low-sulfur scrap steel is used, with industrial pure iron added for products with very low P and S content requirements.

- Argon Bottom-blowing and Wire Feeding Refining: These techniques significantly reduce the number and size of non-metallic inclusions in the steel liquid.

- Strict Raw Material Control: Materials such as scrap steel, alloys, furnace lining materials, and stopper rods are carefully sourced, stored, and used according to technical specifications.

Table 3: Summary of Steel Liquid Quality Control Measures

| Measure | Description |

|---|---|

| Raw Material Selection | Use high-quality low-P, low-S scrap steel; add industrial pure iron as needed. |

| Argon Bottom-blowing | Reduces non-metallic inclusions by stirring the steel liquid and promoting inclusion removal. |

| Wire Feeding Refining | Further refines the steel liquid by adding refining agents through wire feeding. |

| Raw Material Control | Strict procurement, storage, and use of critical materials. |

3.2 Surface Quality Control

The surface quality of key steel castings is stringently controlled to ensure good appearance and minimal defects. For castings that allow welding repairs, all surface defects are addressed before final heat treatment. For those that do not allow welding repairs, rigorous process design and operational control are essential.

3.2.1 Excessive Magnetic Mark Defects

Magnetic particle inspection is conducted on key steel castings before delivery. Excessive magnetic mark defects, often indicating microscopic porosity or shrinkage, must be avoided. These defects frequently occur in specific regions, such as between risers, due to improper solidification sequencing and insufficient temperature gradients. To address this, measures such as adhering to sequential solidification principles and using chills to increase temperature gradients in defect-prone areas are employed.

Table 4: Measures to Address Excessive Magnetic Mark Defects

| Measure | Description |

|---|---|

| Sequential Solidification | Ensure castings solidify in a controlled sequence to minimize porosity and shrinkage. |

| Use of Chills | Increase temperature gradients in defect-prone areas to promote better solidification. |

3.2.2 Slag and Porosity Defects

Slag and porosity defects are common in casting production, often appearing on the upper surface of the pouring position, beneath cores, or in dead corners of the casting. To prevent these defects, the gating system is carefully designed and optimized using MAGMA software simulations to ensure smooth filling and prevent turbulence and splashing. Additionally, the use of refractory brick tubes for the downsprue, filtration systems, and proper control of steel liquid standing time before pouring contribute to minimizing slag and porosity defects.

Table 5: Measures to Prevent Slag and Porosity Defects

| Measure | Description |

|---|---|

| Gating System Design | Ensure smooth filling and optimize using MAGMA software simulations. |

| Use of Refractory Brick Tubes | Prevent slag entry into the casting. |

| Filtration Systems | Use filters to remove slag and stabilize the flow of steel liquid. |

| Steel Liquid Standing Time | Properly control standing time to allow for slag and inclusion floatation and aggregation. |

3.3 Internal Quality Control

Internal defects in key steel castings, primarily porosity and shrinkage, are controlled through careful process design and manufacturing practices. For porosity defects, particularly invasive porosity, measures such as changing the molding sand composition, optimizing core sand formulations, and improving ventilation in the mold are employed. For shrinkage defects, good feeding conditions are established, and casting simulation software is used to select optimal casting process schemes.

Table 6: Measures to Address Internal Defects

| Defect Type | Measure |

|---|---|

| Porosity (Invasive) | Change molding sand composition; optimize core sand formulations; improve mold ventilation. |

| Shrinkage | Establish good feeding conditions; use casting simulation software for process optimization. |

4. Case Studies

4.1 Tight Lock Coupler Shrinkage and Porosity Defects

The tight lock coupler, with its thin-walled and uneven thickness, is prone to cracks and shrinkage defects. Through simulations using MAGMA software and process optimizations, such as adopting multiple small insulation risers, using chromite sand预埋芯, and setting anti-crack ribs, the crack and shrinkage issues were resolved, ensuring the internal quality of the casting.

4.2 Brake Disc Outer Circular Surface Defects

The brake disc, particularly its outer circular surface, is susceptible to porosity defects. These defects, mainly invasive porosity, were addressed by changing the molding sand composition, optimizing the core sand formulation, and improving ventilation in the mold. The resulting reduction in gas generation and improved ventilation contributed to minimizing porosity defects.

5. Conclusion

The high quality requirements of critical steel castings significantly increase the difficulty of their process design and production process control. In terms of process design, it is necessary to fully utilize casting solidification simulation software to optimize the casting process, adopt an open gating system, ensure a smooth mold filling process without turbulence, and provide a certain margin for riser feeding to ensure process stability. In terms of raw and auxiliary materials, it is advisable to boldly apply new materials such as coated sand with low gas evolution and risers with high heat generation efficiency. From the manufacturing perspective, the use of intelligent and digital equipment should be increased to minimize the impact of manual operations. In terms of process control, it is crucial to strengthen process supervision and inspection. Manufacturers with the capability can apply visualization technology to product quality inspection and assessment to meet the needs for real-time, online, and rapid operations. Only by doing so can the product quality of critical steel castings be comprehensively improved, effectively ensuring the running safety of high-speed trains.