This paper focuses on the issues of shrinkage skin and shrinkage cavities in the production of ductile iron reducer housings through lost foam casting. By optimizing the gating system and changing it from top – gating to bottom – gating, the turbulence of molten iron during pouring is effectively reduced, thereby solving the problem of shrinkage skin on the surface of the reducer housing. Additionally, a new heat – dissipation process is explored to address the shrinkage cavity defects in the hot – spot areas of the casting. The experimental results demonstrate that after changing the gating system to bottom – gating, the surface shrinkage skin defect of the casting is completely resolved, and the shrinkage cavity defect is also addressed. Moreover, this process is simple and has a high process yield.

1. Introduction

Lost foam casting is a modern casting technology with unique advantages such as good surface quality, high dimensional accuracy, and high process yield. It has been widely used in the production of various castings, especially in the production of ductile iron parts. The reducer housing, which requires high strength, toughness, wear resistance, and shock resistance, is usually made of QT450 – 10 ductile iron. Given the characteristics of the reducer housing, such as complex geometry and large differences in wall thickness, lost foam casting technology is a suitable choice. However, during the production process, problems like shrinkage skin and shrinkage cavities frequently occur, which seriously affect the quality of the reducer housing and the performance of the entire product. Therefore, it is of great significance to study and solve these problems.

2. The Original Process of Ductile Iron Reducer Housing

2.1 Process Parameters and Composition

The combination process of the reducer housing is shown in Figure 1. The process allowance on the end face is designed to be 4 mm. The tapping temperature ranges from 1580 – 1600 °C, the pouring temperature is between 1370 – 1440 °C, the pouring negative pressure is – 0.06 – 0.04 MPa, and the negative pressure holding time is 900 s. The chemical composition of the reducer housing made of QT450 – 10 is shown in Table 1.

| Main Elements | C | Si | Mn | P | S | Mg | RE |

|---|---|---|---|---|---|---|---|

| Content | 3.5 – 4.0 | 2.0 – 3.0 | ≤ 0.45 | ≤ 0.05 | ≤ 0.025 | 0.02 – 0.06 | 0.015 – 0.04 |

2.2 Problems in the Original Process

Although the mechanical properties of the Y – type sample meet the requirements of QT450 – 10 and the nodularity rate of 2 – 3 levels also meets the technical requirements of the ductile iron reducer housing, problems such as shrinkage porosity, shrinkage cavities, and shrinkage skin occur during the trial production of the reducer housing by lost foam casting. During small – batch production, a large proportion of shrinkage skin appears on the end face of the reducer housing, and shrinkage cavities are found at the geometric hot – spots.

3. Formation Reasons of Shrinkage Skin and Shrinkage Cavities in the Reducer Housing

3.1 Formation Reasons of Shrinkage Skin

3.1.1 General Reasons for Carbon – related Defects in Lost Foam Casting

Carbon – related defects are common in lost foam casting, and shrinkage skin is a typical manifestation. It usually appears as a pitted and orange – peel – like surface on the upper part of the casting after cleaning. Shrinkage skin defects often occur at the last – flowing or “cold – end” part of the molten metal, generally at the top, vertical sidewalls, or dead – end corners of the casting. The copolymer foam pattern used in lost foam casting decomposes when heated, generating a large number of gaseous, liquid, and solid pyrolysis products. The transfer process of these products is affected by many factors, resulting in diverse states, compositions, and discharge forms, which is the fundamental reason for the formation of carbon – related defects in lost foam casting.

3.1.2 Influence of the Pouring System on Shrinkage Skin

The original process of the reducer housing is a top – gating structure in appearance, but actually a mid – bottom gating process using the cavity as the runner. The casting is a rotating body with an upper thickness of 35 mm, and the bottom thickness rapidly decreases from 50 mm to 13 mm. The internal gate of the original process is designed on the top surface. During pouring, the high – temperature molten iron enters the top surface of the white pattern from the internal gate. Instead of filling the mold from top to bottom step by step, the high – temperature molten iron directly penetrates the thick – walled area at the top, uses the top of the cavity as the runner, and then fans out and fills downward when it reaches the thin – walled area. After reaching the bottom, it fills upward, resulting in a mid – bottom gating turbulent filling method. This causes “cold – end” areas in the thick and dead – end areas at the top and sides, leading to the formation of shrinkage skin defects.

3.2 Formation Reasons of Shrinkage Cavities

3.2.1 Basic Principles of Shrinkage Cavity Formation in Ductile Iron Castings

The fundamental reason for the formation of shrinkage cavities in ductile iron castings is that during the liquid shrinkage and solidification of the alloy, a certain part of the casting (usually the hot – spot area that solidifies last) cannot be timely compensated with liquid metal, resulting in irregularly shaped holes with rough walls at that location.

3.2.2 Specific Reasons for Shrinkage Cavities in the Reducer Housing

For the reducer housing, the chemical composition meets the requirements as the mechanical properties of the Y – type sample meet the QT450 – 10 standard and the nodularity rate is up to standard. Also, from the observation of the surface quality of the reducer housing, there are no cold shuts or sand – sticking problems, ruling out the influence of nodularizing treatment temperature, pouring temperature, and negative pressure on the shrinkage cavities. The shrinkage cavity defects of the reducer housing mainly exist in the thick – walled position of the side – processed holes, which is mainly caused by geometric hot – spots. Therefore, to solve the shrinkage cavity problem of the reducer housing, it is necessary to start from the casting process measures, change the casting cooling structure, increase the heat – dissipation surface area, reduce the local modulus, and eliminate the geometric hot – spots of the casting.

4. Solutions and Verifications for Reducer Housing Defects

4.1 Solutions for Reducer Housing Shrinkage Skin

4.1.1 Optimization of the Pouring System

The shrinkage skin of the reducer housing is mainly caused by the unreasonable design of the pouring system, which leads to a mid – bottom gating filling method and turbulent flow of molten iron during pouring. The solution is to redesign the pouring system and change it to a bottom – gating system. As shown in Figure 2, in the new bottom – gating system, the filling method is pure bottom – gating. During the filling process, the high – temperature molten iron fills the mold steadily from the bottom up. As a result, the low – temperature molten iron at the front end and the incompletely gasified products of the white pattern stay at the processing allowance position on the top surface of the cavity, obtaining a casting with a sound surface.

4.1.2 Calculation of the Pouring System Parameters

The original casting process design was unreasonable, resulting in a cumbersome bonding process, disorderly filling, and shrinkage skin defects on the casting surface. After redesigning the casting process to change from top – gating to central closed bottom – gating and canceling the slag pocket on the upper end face, the following calculations were carried out for the pouring system:

- Pouring time calculation formula: \(t = 24S\) (the specific meaning of S needs to be determined according to the actual situation in the process).

- Calculation formula for the average static pressure head height of bottom injection (\(P = C\)): \(H_{p}=H_{0}\), and \(H_{p}=34 cm\) in this case.

- Calculation formula for the minimum cross – sectional area of the internal gate: \(A_{g}=\frac{G}{0.31 t v \sqrt{H_{p}}}=3.46 cm^{2}\). This formula is calculated according to the sand – mold casting. In actual production, according to experience and relevant data, for lost foam casting, the minimum cross – sectional area of the internal gate is generally slightly larger than that of sand – mold casting. Considering the casting structure, the new internal gate is designed as a central casting, with four internal gates. The cross – sectional size of each internal gate is \((7 + 1×40)mm\), and the cross – sectional area of the internal gate is \((11.2 – 12.8) cm^{2}\). The straight – runner length is designed to be 480 mm with a pressure head of 200 mm.

4.1.3 Verification of the Shrinkage Skin Solution

After conducting tests according to the new casting process and mass – producing 2000 pieces for verification, the surface quality of the castings produced by the new casting process is qualified, and no batch – scale surface shrinkage skin defects occur again. As shown in Figure 3, the left figure is a casting with shrinkage skin before process optimization, and the right figure is a qualified casting after process optimization.

4.2 Solutions for Reducer Housing Shrinkage Cavity Defects

4.2.1 Limitations of Traditional Methods

For casting shrinkage cavity defects, the traditional solutions include setting risers at the hot – spot areas to compensate for the volume change of the metal liquid during the casting formation process and eliminate shrinkage cavities, and using a chilling system, usually using chills to make the hot – spot area form an artificial end – zone, creating a sequential solidification to eliminate shrinkage cavity defects. However, for the lost foam casting of the reducer housing, these two methods are not applicable. Adding risers reduces the process yield of the reducer housing casting and increases the overall process difficulty. When using the chill process, due to the characteristics of lost foam casting, the chills are likely to fall off during molding, and may also cause casting deformation, increasing the process difficulty, affecting the quality stability of the reducer housing, and increasing the casting cost.

4.2.2 New Heat – Dissipation Process

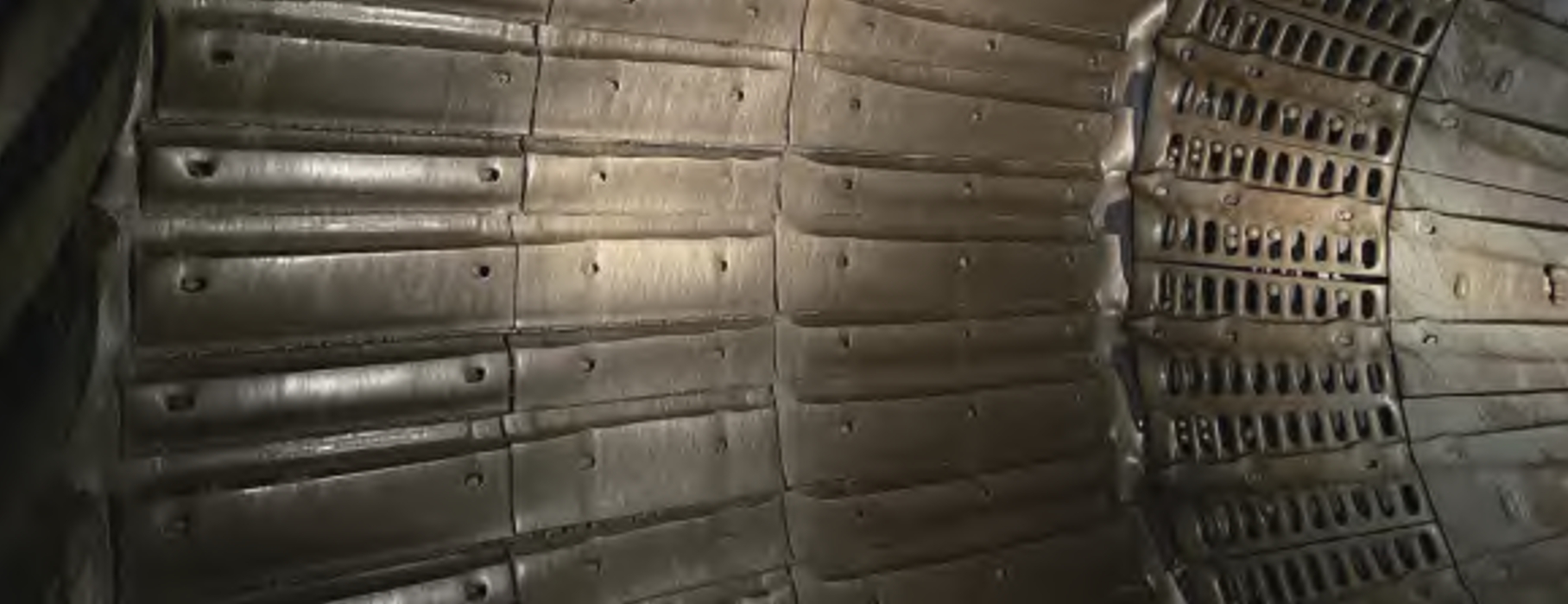

A new lost foam casting process, the heat – dissipation process, has been developed to address the shrinkage cavity problem in the hot – spot areas of ductile iron. The core purpose of the heat – dissipation process is to change the casting structure, increase the heat – dissipation surface area, reduce the modulus of the hot – spot area of the casting, and during the solidification stage, the negative – pressure gas takes away a large amount of heat, achieving a chilling effect. The specific method is to bond foam sheets (hereinafter referred to as heat – dissipation sheets, as shown in Figure 4) at the hot – spot positions of the casting. After that, through processes such as coating, drying, box – filling, molding, and pouring, qualified castings are produced. During the pouring and solidification process of the lost foam casting of cast iron, negative pressure is continuously applied. When the negative – pressure pump is working, cold air enters from the upper surface of the sand box, exchanges heat with the casting and the heat – dissipation sheets, and takes away the heat. The heat – dissipation sheets have a large specific surface area, which reduces the local modulus of the casting. The cold air takes away a large amount of heat, and a micro – channel flow heat transfer is formed between the local molding sand in contact with the casting and the heat – dissipation sheets, creating a chilling zone with a large temperature difference. The heat – dissipation sheets play the role of chills, making the local solidification mode of the casting similar to sequential solidification, thus eliminating casting shrinkage cavity and shrinkage porosity defects. The schematic diagram of the heat – dissipation sheet process principle is shown in Figure 5. The heat – dissipation sheet process has the advantages of simple and convenient operation, little influence on the casting process, almost no impact on the process yield of the reducer housing casting, and simple post – processing of the reducer housing.

4.2.3 Verification of the Shrinkage Cavity Solution

The original process of the reducer housing casting had shrinkage cavity defects in the bolt through – holes, as shown in Figure 6. By analyzing the casting structure, it was found that the shrinkage cavity position of the reducer housing belonged to a geometric hot – spot, with a high shrinkage cavity tendency, which was consistent with the shrinkage cavity defects in batch production. After comprehensive consideration of various factors, the heat – dissipation process was used. As shown in Figure 7, in the blanking and bonding process, 12 heat – dissipation sheets with a size of \((50×30×7)mm\) were bonded in the hot – spot area of the casting, and the other process steps remained unchanged. After trial production and machining verification, the bolt through – holes of the reducer housing were normal without quality problems, as shown in Figure 8. During batch production using the heat – dissipation process, 2000 reducer housings were continuously produced, and no batch – scale shrinkage cavity defects appeared in the bolt through – holes after processing.

5. Conclusion

(1) By optimizing the gating system process, the filling process during pouring becomes stable, and the front – end molten iron with impurities can be collected by using the process allowance, effectively solving the casting shrinkage skin defect. (2) For the shrinkage cavities caused by hot – spots in the lost foam casting production of ductile iron parts, the traditional riser and chill methods have high process difficulties. A new process method, the heat – dissipation sheet process, is designed. By setting a certain number of heat – dissipation sheets at the hot – spot areas of the casting, the local heat – dissipation speed is enhanced, the geometric hot – spots of the casting are eliminated, and the casting shrinkage cavity defect is solved. The heat – dissipation sheet process has been verified by the reducer housing casting, proving that this process meets the design requirements and can be used as a new method to solve shrinkage cavities in lost foam casting.

6. Future Research Directions

Although the shrinkage skin and shrinkage cavity problems of the reducer housing have been effectively solved in this study, there is still room for further improvement in the lost foam casting process. Future research can focus on the following aspects: (1) Further optimize the design of the heat – dissipation sheet, such as studying different shapes, sizes, and materials of the heat – dissipation sheet to improve its heat – dissipation efficiency and the quality of the casting. (2) Explore the influence of different negative – pressure parameters on the heat – dissipation process and the quality of the casting, and optimize the negative – pressure process to achieve better casting results. (3) Combine the heat – dissipation process with other advanced casting technologies to develop more efficient and high – quality casting processes for complex castings.

7. Acknowledgments

We would like to express our sincere gratitude to all those who have provided help and support during the research process. Thanks to the colleagues in the laboratory for their assistance in experiments and data collection. Also, we are grateful for the support from the company’s management, which provides necessary resources and conditions for this research.