This article comprehensively explores the lost foam casting process. It begins with an overview of its development status in China, including the so – called “lost foam casting circle” and the current challenges. Then, it delves into the existing problems in its application, the unique process characteristics, and the suitable scope of application. Common casting defects in lost foam casting and corresponding countermeasures are analyzed in detail. Finally, the development direction of lost foam casting in the Chinese context is predicted, aiming to provide a comprehensive understanding and reference for the development of the lost foam casting industry.

1. Introduction

Lost foam casting is a modern casting technology that has gained significant popularity in recent years. It offers several advantages over traditional casting methods, such as high – precision casting, simplified casting processes, and good surface quality of castings. However, like any technology, it also faces challenges and limitations. In China, the development of lost foam casting has gone through a long – term process, and currently, it is in a crucial stage of development.

2. The Current Situation of Lost Foam Casting in China

2.1 The “Lost Foam Casting Circle”

The lost foam casting industry in China is experiencing a boom. According to incomplete estimates, there are approximately 2,500 – 3,000 large – and medium – sized lost foam casting enterprises, and the actual number is even larger, with the number still on the rise. The types of equipment, production organization methods, raw and auxiliary materials, and process technologies vary widely, showing a lack of uniformity.

| Situation | Description |

|---|---|

| Positive Side | The number of enterprises is increasing, indicating potential market vitality. |

| Negative Side | Some enterprises, especially small and micro – enterprises, face high casting rejection rates. Many rely on post – repair for low – end castings, resulting in the phenomenon of “easy to understand but difficult to implement” in production. |

This situation has created a “lost foam casting circle” where small and medium – sized enterprises struggle to produce high – quality castings despite the recognized advantages of the lost foam casting process.

2.2 The Crucial Stage of Development

Lost foam casting is an experience – based technology in the Chinese context, with many restrictive conditions and complex mechanisms. Some enterprises have mastered the key points and can produce high – quality castings smoothly, while others, especially small and micro – enterprises, still face difficulties. The main reasons for the failure of some enterprises include weak technical strength, disconnection between actual operation and process specifications, and a lack of attention to fine management in the production process.

Large and medium – sized enterprises, on the other hand, have entered a stage of stable mass production, mainly due to their strong technical strength, high – quality awareness, and precise operation and management.

3. Existing Problems in the Application of Lost Foam Casting

3.1 Defects in the Casting Process

Lost foam casting has several inherent problems that can lead to casting defects.

| Defect | Cause |

|---|---|

| Internal slag inclusion and gas entrapment | Disorderly molten iron flow during casting. |

| Carbon accumulation | Low – quality white molds, narrow gas – discharge channels in coatings, and the unique filling method of molten iron and negative pressure effect. |

| Adherent sand | Low – strength coatings, thin coatings, gas entrainment during pouring, and insufficient filling of dry sand in complex mold cavities. |

| Deformation | Deformation of the white mold before and during the casting process, uneven stress during filling and solidification. |

| Porosity | Increased gas volume due to white mold pyrolysis, poor coating permeability, narrow gas – discharge channels, and improper negative – pressure pouring. |

| Collapse of the mold | Uneven negative pressure in the sand box, strong heat flow and gas flow impact during pouring. |

3.2 Dependence on Raw and Auxiliary Materials

The quality of castings in lost foam casting is highly sensitive to the performance and stability of raw and auxiliary materials. For example, the quality of white molds in China is generally low, mostly using building and packaging – grade white molds made from waste materials of packaging and building raw materials, which often contain flame retardants that increase slag content.

3.3 Complex Influence of Process Conditions

The process conditions in lost foam casting, such as negative – pressure conditions, vibration during dry – sand filling, and the temperature of molten iron pouring, have complex and inter – related effects on the quality of castings. The existing theoretical understanding of these effects is still incomplete, making it difficult to optimize the process accurately.

4. Process Characteristics and Application Scope of Lost Foam Casting

4.1 Process Characteristics

The most significant advantage of lost foam casting is the elimination of the mold – removal process. After the white mold is buried in the molding sand, it does not need to be removed, which simplifies the casting process and improves the dimensional accuracy and surface quality of castings.

| Advantage | Derived Benefit |

|---|---|

| No need for sand cores | Can handle complex – shaped castings more easily without the trouble of making and assembling sand cores. |

| No need for mold parting | The casting process design becomes more flexible without the need to consider mold – parting surfaces. |

| Flexible gating and risering design | Gating and risering can be designed more freely, facilitating the control of molten iron flow and the feeding of castings. |

| Dry – sand molding | No binder is required, and the sand can be recycled easily. The casting shake – out process is also convenient. |

| High production efficiency | It is easy to achieve mechanization and automation, with a small initial investment, small floor space, and low labor intensity. |

| Increased casting density | Due to negative – pressure pouring and solidification, the density of castings is increased. |

| Good workshop environment | The gas generated during the gasification of the white mold can be easily collected, treated, and discharged. |

However, lost foam casting also has strict requirements for production conditions. The performance and stability of raw and auxiliary materials, the performance of vibration tables, and the drying of white molds and coatings all have a significant impact on the quality of castings.

4.2 Application Scope

Based on the basic principles of lost foam casting and the characteristics of the process, the following is a summary of its applicable scope.

| Classification | Applicable Castings |

|---|---|

| By Material | Gray iron castings are the most suitable, followed by ductile iron, steel castings, and finally aluminum castings. |

| By Structure | Castings with uniform wall thickness, complex structures, and a wall – thickness range of 10 – 20 mm, such as box – type and shell – type castings. |

| By Size | Medium – sized castings weighing from a dozen to several hundred kilograms are the most suitable. For large – sized castings, resin – sand molding is often used, such as automotive cover – panel stamping dies and machine – tool beds. |

| By Surface Finish Requirements | For steel castings, those with requirements of no – machining or less – machining and relatively low requirements for internal defects, such as wear – resistant, heat – resistant, and corrosion – resistant castings. |

| By Production Batch | For small and medium – sized castings, a batch size of more than 10,000 pieces is suitable. The white mold is formed by molds, and pouring is carried out on a production line. For large – sized castings, the white mold is processed by cutting plates and CNC machine tools, and resin – sand molding with normal – pressure or negative – pressure pouring (with dust and smoke removal) is used. |

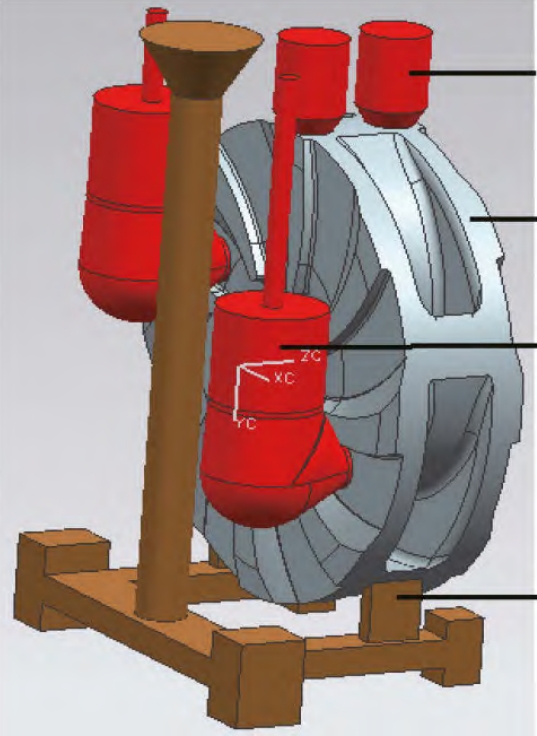

[Insert a picture here showing different types of castings suitable for lost foam casting, such as a box – type casting and a shell – type casting]

5. Common Defects in Lost Foam Castings and Corresponding Process Measures

5.1 Treatment of Slag Inclusion Defects

Slag inclusion defects in lost foam castings are mainly caused by the entry of foreign matter into the cavity, such as broken dry – sand particles, coating residues from the white mold, and gasification residues of the white mold.

| Measure | Description |

|---|---|

| Sealing | Seal the dry – sand cavity tightly, especially at the joints of the white mold, gating system, and the connection between the pouring cup and the sprue. |

| Discharge | Use methods such as slag – discharge and gas – discharge risers, burning during pouring, overflow risers, and vent holes (ropes) to discharge foreign matter. |

| Dispersion | For complex – structured castings where foreign matter cannot be completely discharged, use methods such as top – gating and multiple gating to disperse the foreign matter. |

5.2 Treatment of Carbon Accumulation Defects

Carbon accumulation defects are common in lost foam casting of steel and ductile – iron castings, often manifested as wrinkled surfaces on the upper part of the castings after cleaning.

| Measure | Description |

|---|---|

| Material Selection | Use low – carbon mold materials. For example, the copolymer material STMMA is significantly better than polystyrene EPS material. |

| Mold Density Control | Use low – density white – mold patterns. While reducing the density, ensure that the white mold has sufficient stiffness and strength. |

| Carbon – Discharge Process | Strengthen carbon – discharge measures, such as reserving vent holes in the mold, exhausting smoke through the gating and risering system, improving the permeability of the coating inside the casting, and strengthening the negative – pressure stability in large – volume semi – enclosed cavities of the casting. |

| Drying | Strengthen the drying effect of the white mold and the coating. Ensure that the white mold and the coated white mold are thoroughly dried, especially in internal – angle and blind – hole parts of the casting structure. |

5.3 Treatment of Adherent Sand Defects

Adherent sand defects in lost foam casting can be divided into mechanical and chemical adherent sand. Mechanical adherent sand is more common, while chemical adherent sand mainly occurs in steel castings and slender inner – hole parts of castings.

| Cause of Adherent Sand | Countermeasure |

|---|---|

| Low – strength coating | Improve the normal – temperature and high – temperature strength of the coating to prevent coating damage during the process. |

| Thin coating | Ensure an appropriate coating thickness to maintain overall strength without reducing permeability. |

| Gas entrainment during pouring | Control the amount of gas entrained during pouring, and keep the sprue full during large – flow pouring. |

| Insufficient filling of dry sand | Strengthen the vibration – filling effect of the vibration table on dry sand in the mold cavity, especially for complex – structured castings. |

| Chemical reaction in some parts | For steel castings and parts with slender inner – holes, use high – temperature – resistant coatings. |

5.4 Treatment of Deformation Defects

Deformation is a common defect in lost foam castings, especially for thin – walled and low – stiffness castings.

| Stage of Deformation Cause | Countermeasure |

|---|---|

| Before molding | Design a reasonable mold structure to ensure that the molded pattern does not deform. Pay attention to the filling method, cooling method, and demolding method to ensure uniform density and cooling of the pattern. |

| During molding | When handling the pattern, be careful not to cause collisions or uneven stress. Use a suitable vibration table to ensure uniform filling of dry sand and avoid sand flow – induced deformation. |

| During pouring and solidification | Pay attention to the pouring process to avoid over – heating of the pattern. Design a reasonable gating system and consider the solidification sequence to reduce internal stress. |

5.5 Treatment of Porosity Defects

Porosity defects in lost foam castings are mainly caused by excessive gas generation, poor coating permeability, and improper negative – pressure pouring.

| Measure | Description |

|---|---|

| Mold Density Control | Control the pre – expansion molding density of the white mold. Reduce the density of the mold under the premise of ensuring the stiffness of the mold to reduce gas generation. |

| Coating Permeability | Ensure good coating permeability, especially high – temperature permeability. |

| Exhaust Design | Design a reasonable exhaust channel, such as setting exhaust and overflow risers at the upper – side of thick – walled parts. |

| Drying | Ensure that the mold and the coating are thoroughly dried to avoid excessive gas generation caused by moisture. |

| Pouring Design | Design the position, number, and direction of the inner gate reasonably. Control the negative – pressure during pouring to ensure uniform negative – pressure in the cavity. |

5.6 Treatment of Collapse (Mold Failure) Defects

Collapse, also known as mold failure, is a serious defect in large – sized lost foam castings, which can cause casting scrap and even safety accidents.

| Measure | Description |

|---|---|

| Negative – Pressure Balance | Keep the negative pressure in the sand grains around the white mold and in the inner cavity of the sand box balanced during the pouring process. |

| Sufficient Exhaust | Ensure sufficient exhaust speed and volume to maintain the stability of the sand mold. |

6. The Development Direction of Lost Foam Casting in the Chinese Context

6.1 Quality – Oriented Development

The future development of lost foam casting in China should focus on improving the quality of castings. This includes the production of high – end castings and the breakthrough in the production of complex – shaped castings. Large and medium – sized state – owned enterprises and some joint – stock cooperative enterprises are expected to play a leading role in this regard.

| Quality – Oriented Development Aspect | Description |

|---|---|

| High – End Castings | Increase the proportion of high – end casting production, meeting the requirements of high – precision and high – performance products in various industries. |

| Complex – Shaped Castings | Achieve breakthroughs in the production of complex – shaped castings, expanding the application scope of lost foam casting. |

6.2 Theoretical Research and Technological Innovation

It is necessary to strengthen the basic research of lost foam casting, transform the personalized and experience – based lost foam casting technology into a generalized and theoretical technology. This requires strong – strength and technology – intensive enterprises to take the lead in conducting research on the basic principles and key technologies of lost foam casting.

6.3 Rational Development and Industrial Guidance

As the lost foam casting process is not suitable for all types of castings, casting enterprises need to carefully analyze whether their product structure types are suitable for this process. Industry associations, such as the Lost Foam Casting Professional Committee of the China Foundry Association, should play a guiding role in providing policy, market, development, and technical consultations to promote the healthy, sustainable, and benign development of the lost foam casting industry.

7. Conclusion

Lost foam casting is a promising casting technology with unique advantages and challenges. In China, although it has faced some difficulties in the development process, with the continuous improvement of understanding and the emergence of suitable production technologies, it still has broad development prospects. By addressing the existing problems, strengthening quality control, and promoting technological innovation, the lost foam casting industry can achieve better development and make greater contributions to the overall improvement and growth of the Chinese casting industry.