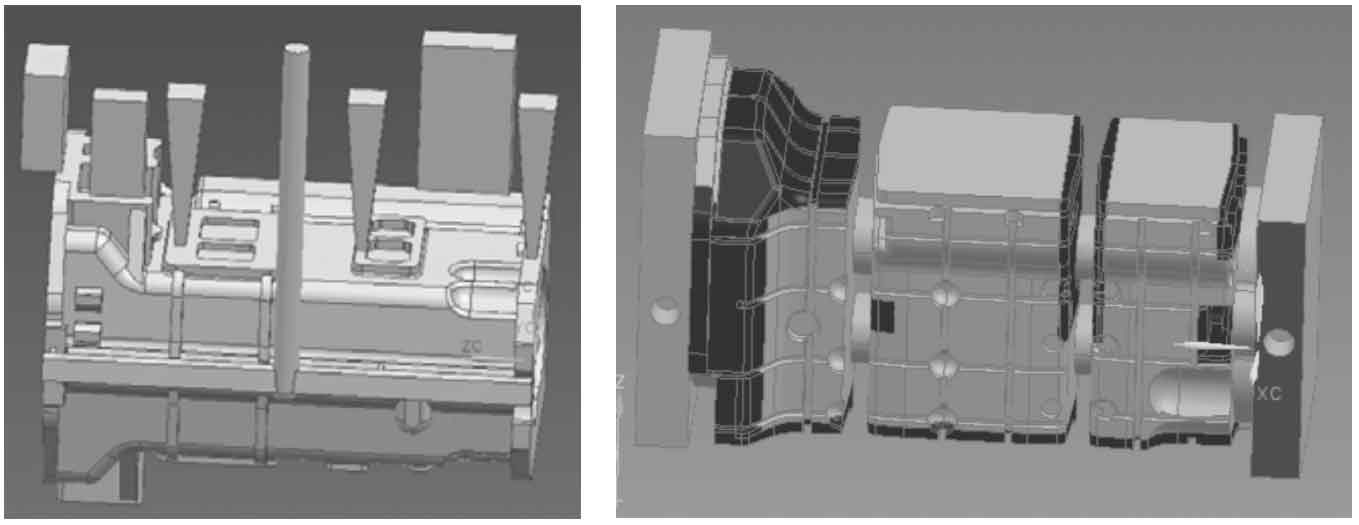

The structure of gearbox shell is shown in Figure 1. Its material is QT500-7, the blank weight is 458 kg, the casting wall thickness is 14.1 mm, and the maximum length is 949 mm. The casting is used for the transmission system of crawler tractor. The casting itself is also used as a load-bearing part. The internal quality requirements are high. The yield strength is required to be ≥ 320 MPa, the tensile strength is required to be ≥ 500 MPa, and the elongation after fracture is required to be ≥ 7%.

1. Dimensional error and defect analysis

The reason why there are many air holes at the top of the casting may be that the resin sand core produces high-temperature chemical reaction after encountering high-temperature molten iron, resulting in large air generation. However, the existing air outlet fails to meet the needs of exhaust, and a large amount of gas accumulates at the top of the sand mold and cannot be discharged.

For the problem of dimensional error, the author believes that the parting process of “integral core” can be used to process the sand core at one time, so that the dimensional accuracy of the sand core can be greatly improved to 0.1 mm. At the same time, the “integral core” scheme only needs to place the sand core on the processing platform at one time, without repeated manual handling, and the processing knife path can be completed at one time. For some areas that cannot be machined by the finishing tool path in the “segmented core” process, the sand core structure that needs finishing in the area shall be trimmed to accurate accuracy by later manual shaping. After the process improvement, the processing of the integral core no longer adopts the processing method of the front and back sides, but the left and right sides are processed on the five axis equipment, which not only improves the structural accuracy of the sand core, but also greatly shortens the production cycle of rapid casting.

2. Process improvement

According to the above defect analysis, three outlet risers with a size of 80 mm, 20 mm and 300 mm need to be placed on the top of the casting, with a slope of 5 °. In this way, the gas generated during pouring can not be discharged at the top of the mold, resulting in pore defects after casting forming. After the process improvement, the processing of sand core will adopt the process scheme of “integral core”. Since the weight of the sand core blank is about 750 kg when the “integral core” scheme is adopted, it is extremely difficult to carry and turn under the existing conditions, so the left and right sides are processed to avoid manual turning of the sand block in the later processing process. In the integral core, the areas where the knife path cannot be processed due to the structural obstruction of the sand core are processed in the form of movable blocks or patches, and the sand core is patched to the corresponding parts with adhesive after processing. The improvement of the process scheme is shown in Figure 4. Gray is sand core and black is patch and movable block. After adopting the “integral core” process, the number of patches and movable blocks produced by parting has increased a lot compared with the “segmented core”, so the workload of laser sintering molding machine is relatively increased. For the “segmented core” process, the working time ratio of five axis digital Moldless precision molding machine, three axis digital Moldless precision molding machine and laser sintering molding machine is about 3:3:2; For the “integral core”, the working time ratio is about 1:1:1. Therefore, it can be seen that in the rapid casting production process of gearbox shell, the three lines of five axis digital modelless precision molding machine, three axis digital modelless precision molding machine and laser sintering molding machine operate at the same time, which not only has the highest work efficiency, but also can best reflect the advantages of short production cycle and quick effect of rapid casting.

After the improvement of the process scheme, the processing time of sand core (Fig. 5) is saved by 13 H. Moreover, because there is no need to turn over, the structural accuracy of the sand core is very good, which is basically controlled within 0.15 mm, and its dimensional accuracy reaches 0.1 mm, which is more difficult for castings with a length of 949 mm. The patch and movable block are still formed by laser sintering molding machine.

After all sand boxes and sand cores are processed, the structural areas where the sand cores cannot be processed shall be bonded with patches and movable blocks. After the binder is completely solidified, the group mold, lower core, check the skin thickness and buckle the box. The sand mold is positioned with positioning pins, the periphery is enclosed with sand boxes, and the top is fixed and reinforced with pressure iron. The pouring temperature is 1420 ℃, and the pouring time is 84 s.