Adding alloying elements to cast iron can improve the strength of gray cast iron. The effects of manganese, some alloying elements and some trace elements on the strength of gray cast iron deserve attention. Manganese can significantly increase the pearlite content in the matrix, appropriately increase the manganese content, and select the appropriate manganese sulfur ratio and manganese silicon ratio can improve the strength of gray cast iron. Proper addition of alloying elements and trace elements in molten iron can have various beneficial effects on the strength of gray cast iron.

Manganese is a common element in cast iron. It combines with sulfur or replaces the iron atom of Fe3C in iron to form (Fe, Mn) 3C. Manganese can inhibit the precipitation of ferrite, promote the formation of pearlite and make austenite easy to decompose. Therefore, manganese can significantly improve the mechanical properties of gray cast iron.

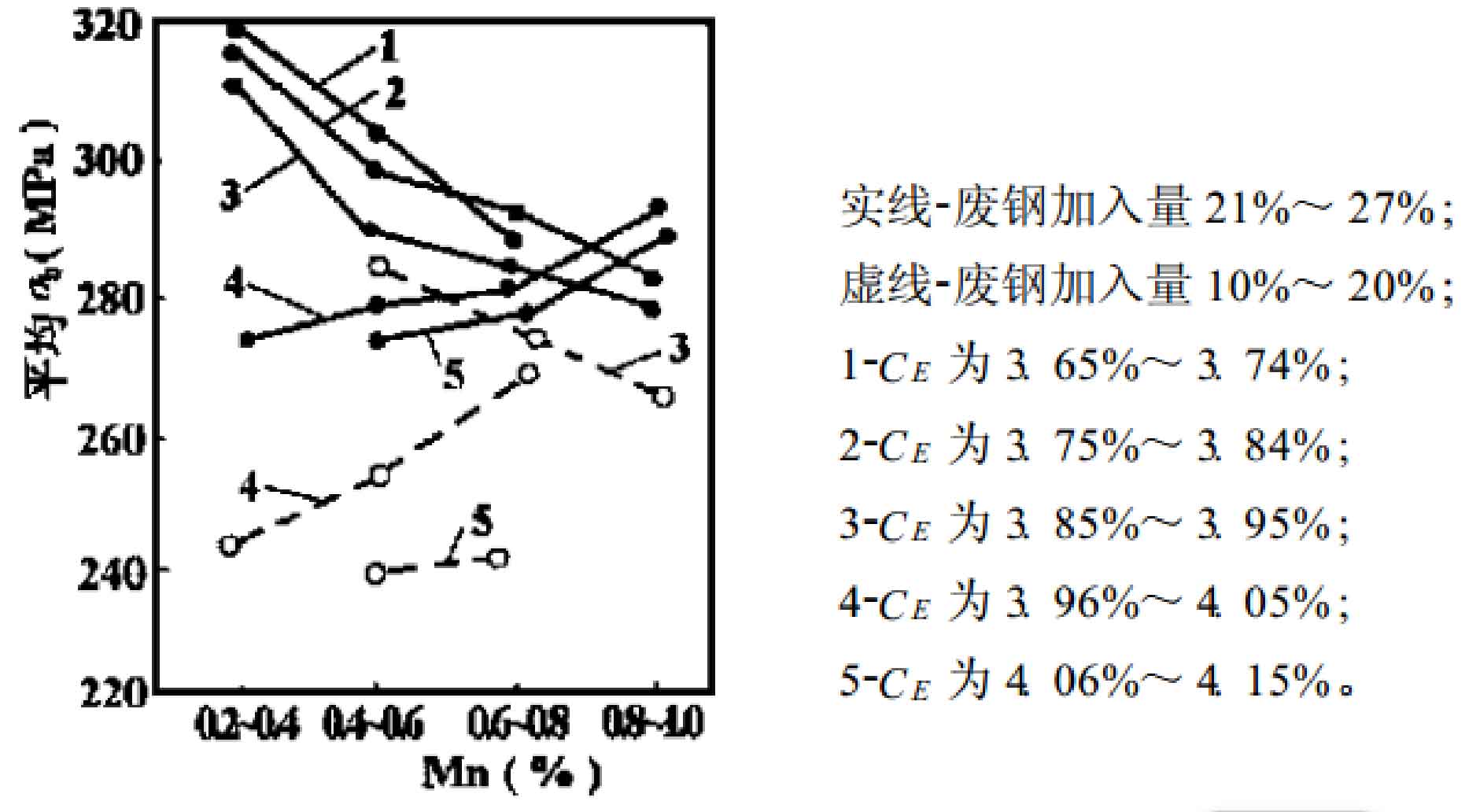

Generally, the manganese content of gray iron castings is 0.4% – 1.0%. When the addition amount of manganese in gray iron is 1.2% – 1.5%, the strength and hardness of gray iron castings are improved, and the compactness and wear resistance are enhanced. When the manganese content exceeds 1.5%, it will show a certain chilling tendency, hinder graphitization, increase the amount of pearlite, refine the structure and strengthen the matrix, and improve the strength of cast iron. However, too high manganese content will increase the precipitated carbides, reduce the mechanical strength and make the processing difficult. Liu Youping pointed out that the relationship between the chemical composition of the test bar and the tensile strength is shown in Figure 1. It can be seen from the figure that the tensile strength of gray cast iron decreases significantly with the increase of carbon equivalent; When the carbon equivalent and manganese content are constant, increasing the amount of scrap in the charge increases the tensile strength of gray cast iron; When the carbon equivalent is 3.65% – 3.95%, the tensile strength decreases obviously with the increase of manganese content, and the optimum addition of manganese is 0.4% – 0.6%; When the carbon equivalent is 3.96% – 4.15%, the tensile strength increases with the increase of manganese content, and the optimum addition of manganese is 0.6% – 0.8%. This is because when the carbon equivalent is low, the amount of graphite in gray cast iron is small and fine. When manganese is added, manganese and sulfur will form the core manganese sulfide of graphite non spontaneous nucleation, which will promote the graphitization of gray cast iron, coarsen and increase the amount of graphite, so as to reduce the tensile strength of gray cast iron; When the carbon equivalent is high, the graphite quantity and size of gray cast iron are large and the pearlite quantity is small. At this time, increasing the manganese content will make manganese show a strong role in promoting pearlite and improve the tensile strength.

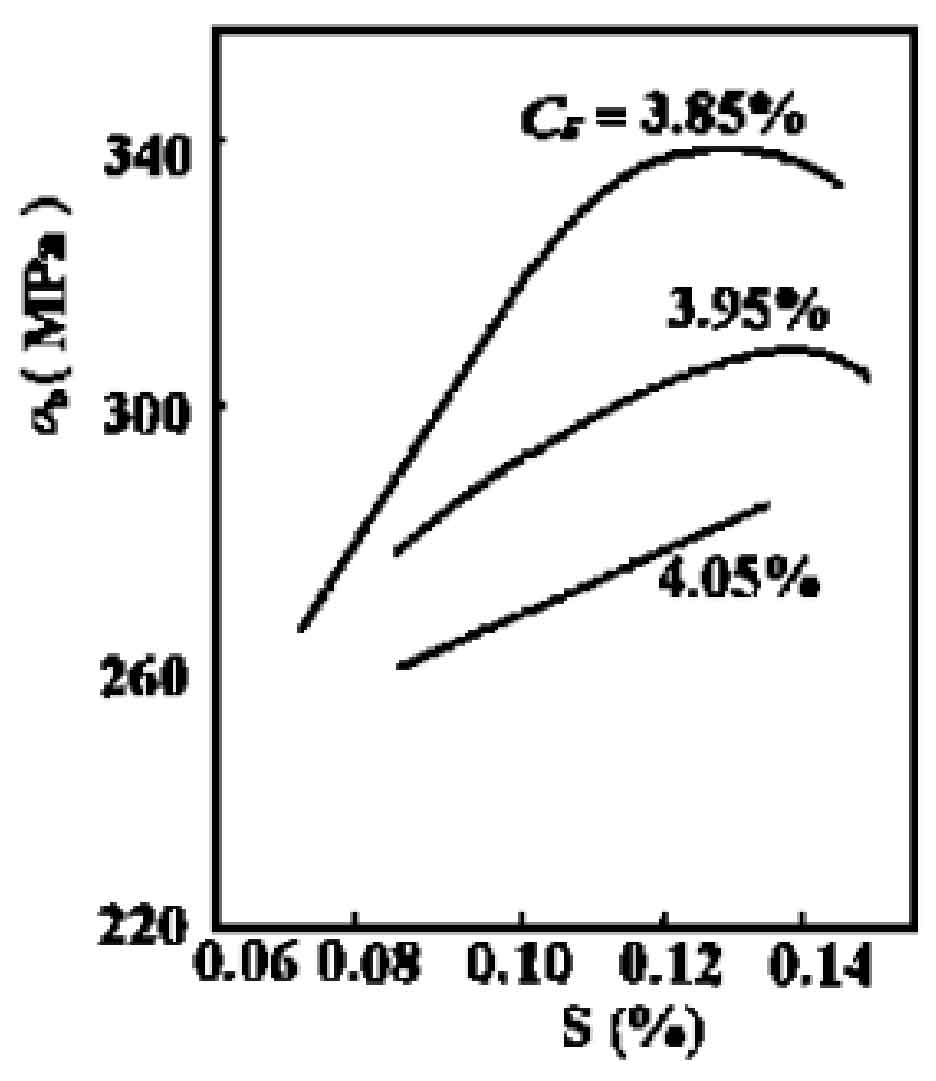

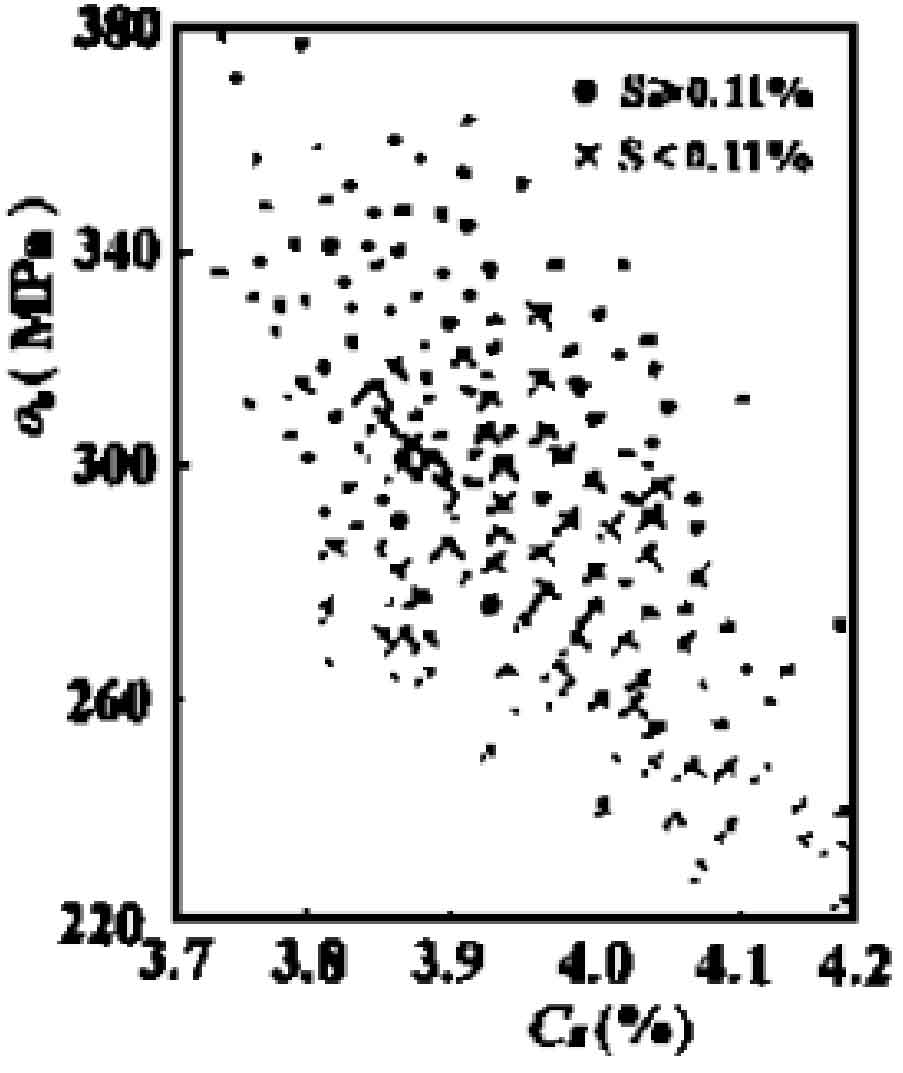

Sulfur is generally regarded as a harmful element, and the content is generally required not to exceed 0.12%. However, the sulfur content of gray cast iron parts with HT250 or above on automobiles and tractors produced by many European manufacturers is usually 0.12% – 0.15%. Liu Youping studied the effect of sulfur content on tensile strength under different carbon equivalent conditions and the effect of carbon equivalent on tensile strength under different sulfur content conditions, as shown in figures 2 and 3 respectively.

It can be seen that when s < 0.11%, the tensile strength is generally less than 260mpa when the carbon equivalent is greater than 4.0%, while when s ≥ 0.11%, the tensile strength is greater than 260mpa when the carbon equivalent is in the range of 3.7% – 4.2%. When the sulfur content is low, the tensile strength increases with the increase of sulfur content. When the sulfur content increases to a certain value, the tensile strength begins to decrease with the increase of sulfur content, For gray cast iron with carbon equivalent of 3.85% and 3.95%, the critical sulfur content is 0.125% and 0.14% respectively. In the final analysis, sulfur affects the mechanical properties of gray cast iron by changing the structure of gray cast iron. Some studies show that within a certain range, sulfur can increase the number of type a graphite, increase the number of eutectic clusters, reduce the section sensitivity and reduce the white tendency. When the sulfur content is 0.027%, 0.078% and 0.143%, with the increase of sulfur content, The amount of graphite increases, and the shape of graphite becomes short and thick. The main reason is that the sulfur in the molten iron will form manganese sulfide with manganese. The melting point of manganese sulfide is 1610 ℃. When the molten iron solidifies, most of the manganese sulfide exists in granular form and may become the core of graphite. Graphite can nucleate and grow under a small undercooling. Therefore, the effect of precipitation and inoculation of graphite is achieved. Sulfur in molten iron not only affects the nucleation of graphite, but also affects the growth of graphite. Sulfur can reduce the solubility of carbon in molten iron, reduce the surface tension of molten iron, and reduce the interface energy between the edge of graphite and molten iron. Therefore, it provides favorable conditions for the nucleation and growth of graphite. However, when the sulfur content in molten iron is too high, it will seriously segregate on the graphite surface, form sulfur rich film, hinder the diffusion of carbon atoms, form supercooled graphite and intergranular inclusions, and deteriorate the mechanical properties of gray cast iron.