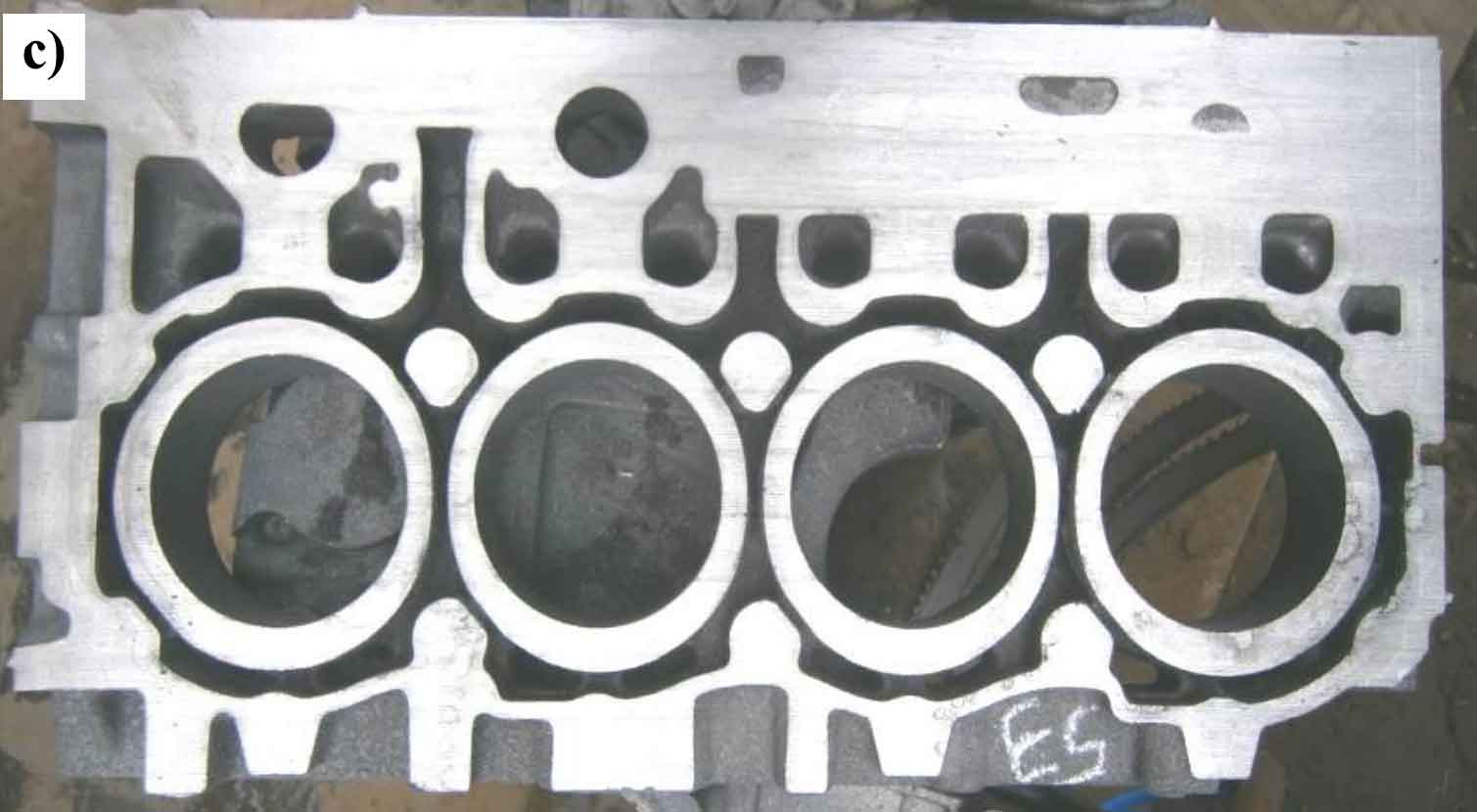

The surface quality of sand castings not only affects the appearance of non machined surface parts of products, but also the external performance of the internal quality of sand castings. One of the key components of automobile engine is automobile cylinder block. The structure of automobile cylinder block is complex, and its dimensional accuracy is also required. The wall of water jacket and oil passage is thin and under the working conditions of high temperature and high pressure, so the performance requirements of sand castings are high. The engines of some mainstream models require high mechanical properties, and the material is ht220-250; The wall thickness of water jacket is about 3mm, which is a typical thin-wall casting, so its sand casting process is also very complex.

At present, the sand casting method of gray cast iron cylinder block of automobile engine mainly adopts green mold gravity casting and clay green sand molding. There are two pieces in each mold, and the pouring amount of each piece is about 120 kg. Due to the different wall thickness and complexity of the cylinder body, the pouring temperature is controlled between 1420 ℃ – 1460 ℃ and the pouring time is 10s-14s. The sand core of the cylinder block is made by triethylamine cold box method, and the curing agent is moisture resistant resin. The increasing output and quality of cylinder block are in sharp contradiction with the low cost of automobile cylinder block. The low cost of automobile cylinder requires simple casting method, short cycle and high production efficiency. The raw material cost of wet mold casting is low, and the mold does not need to be dried and the sand falling cleaning is convenient. Therefore, the process is simple, the molding productivity is high, the production cycle is short, and the sand casting cost is low. It is particularly suitable for the mechanized molding of mass production of sand castings such as automobile, tractor and diesel engine.

Among automotive sand castings, the quality of engine block castings is the most unstable, and the scrap rate fluctuates greatly. The scrap rate is up to about 5%. However, in order to maintain high profitability and competitiveness, automobile parts sand casting enterprises generally locate their products on high-end products with high added value and high sand casting process difficulty, such as cylinder block and cylinder head. The price of such products can reach more than twice the price of ordinary sand castings. However, if the product quality is poor or the scrap rate is high, the result will naturally be futile. Although the cost of wet mold casting is low, due to the addition of water in the mold, the tendency of surface defects such as sand sticking, air hole, sand inclusion and sand hole increases. Therefore, how to reduce the comprehensive scrap rate of wet mold casting has become the main focus and foothold of reducing cost and increasing efficiency. Production practice shows that the internal quality and surface quality of sand castings are affected by the properties of green casting sand. More than 80% of casting defects such as sand holes, sand inclusions, pores and sand sticking of automobile engine cylinder block sand castings are caused by molding sand quality problems or improper use. However, due to the complexity of cylinder block sand castings and high experimental cost, The research on the surface quality of wet casting engine block is still insufficient.

Therefore, the research on the influence of molding sand factors on the surface quality of cylinder block sand castings in the forming process of automobile engine cylinder block by green casting has important engineering application value for controlling the surface quality of cylinder block sand castings and forming automobile engine cylinder block by low-cost casting.