Due to the structural characteristics of the axle housing, the spiral case opening can only be placed upward and horizontally. In the thick part, the spring steel plate position at both ends and the middle volute flange are fixed to form three hot joint areas, which are the parts that need feeding, and each hot joint is isolated, so the pouring system cannot be designed based on the principle of sequential solidification.

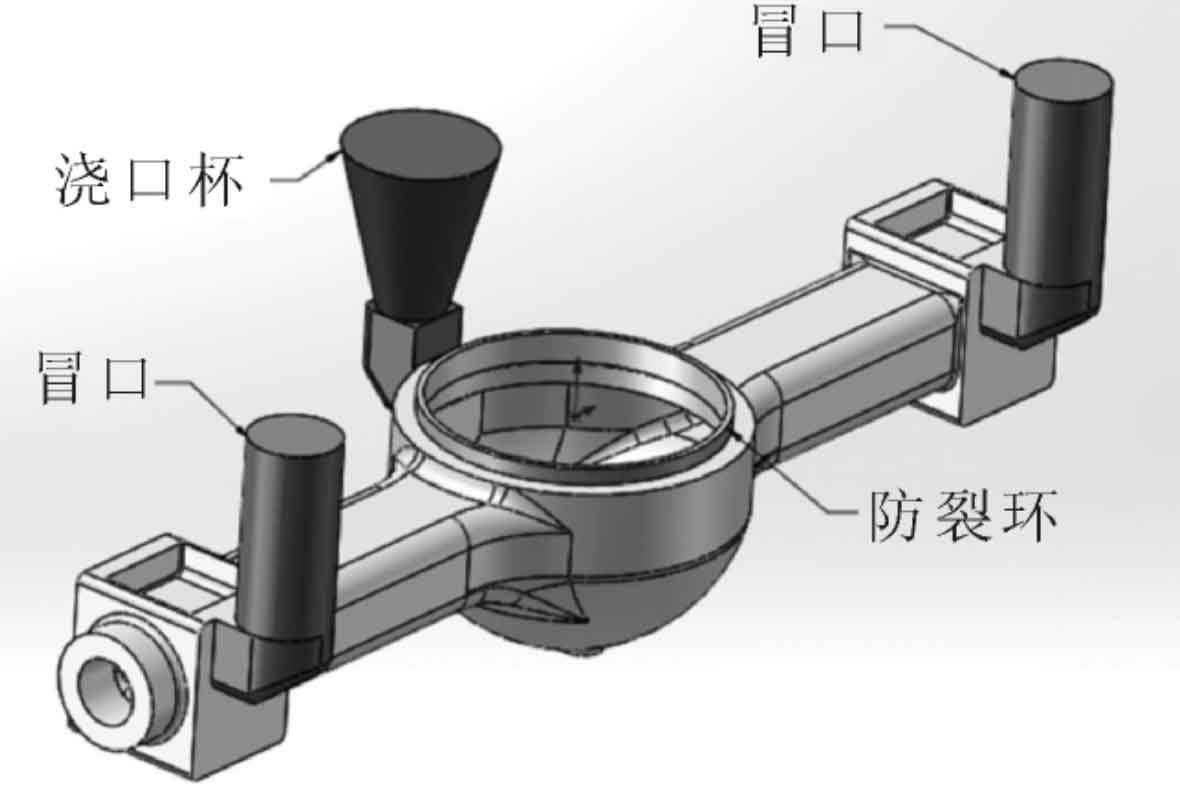

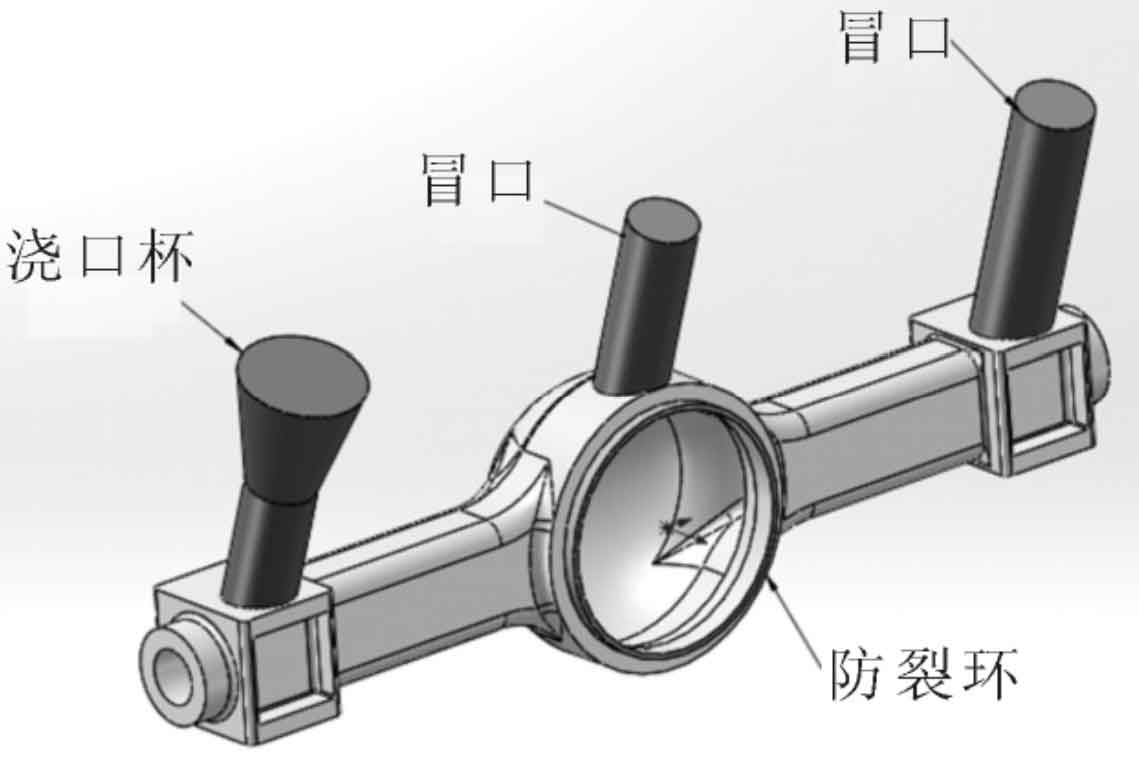

The middle flange is easy to shrink and crack, and an anti crack ring of 8mm is added × 25 mm aligned with the inner opening. Two experimental processes are designed according to lost foam casting experience: ① middle pouring and feeding of risers at both ends, as shown in Figure 1; ② The middle flange surface is placed on the side, the riser is inclined to the parallel surface of the flange by 20 °, one end is poured with a riser, and the middle flange and the other end are respectively provided with a riser, as shown in Figure 2.

Two kinds of foam bead materials are EPS and STMMA. The EPS and STMMA molecular carbon contents are 92% and 69.6% respectively. STMMA is easy to burn at high temperature and less residue. However, the most ideal foam bead for producing high-end lost foam casting steel is EPMMA, and the molecular carbon content is 60%. Not only the carbon content of the lost foam casting steel castings is low, but the residue is very few, but the market price of the bead is too high, so it has no practical production significance. Stmma is the best choice.

The die adopts the integral die opening process or three-stage die opening. It is not easy to smooth the longitudinal gap inside the square cylinder shaft tube at both ends after bonding, so it is avoided to open the mold in the longitudinal direction. The mold is opened together with the pouring system and foamed by stmma at one time.

In order to increase the strength of the white mold structure and reduce the deformation, the white mold density is controlled at 20 ~ 23 G. After natural drying for 4 ~ 6 hours, the foaming integral white mold shall be placed on the formwork support with the French plane as the datum plane to prevent deformation during drying.

Coating is one of the keys of lost foam casting steel bridge shell. Low temperature strength, high temperature strength, fire resistance, high coating hanging and low fluidity are indispensable. Because the cast steel coating on the market can not meet the technical requirements of axle housing, a special coating has been developed in actual production, which has good coating hanging and dripping properties. Formula: 3 parts of sodium bentonite, 3 parts of CMC, 0.5 parts of lignocellulose, 0.5 parts of xanthan gum, 0.5 parts of water-soluble polyvinyl alcohol, 80 parts of 85 bauxite (particle size 200 mesh) and 20 parts of 99 quartz powder (particle size 200 mesh).

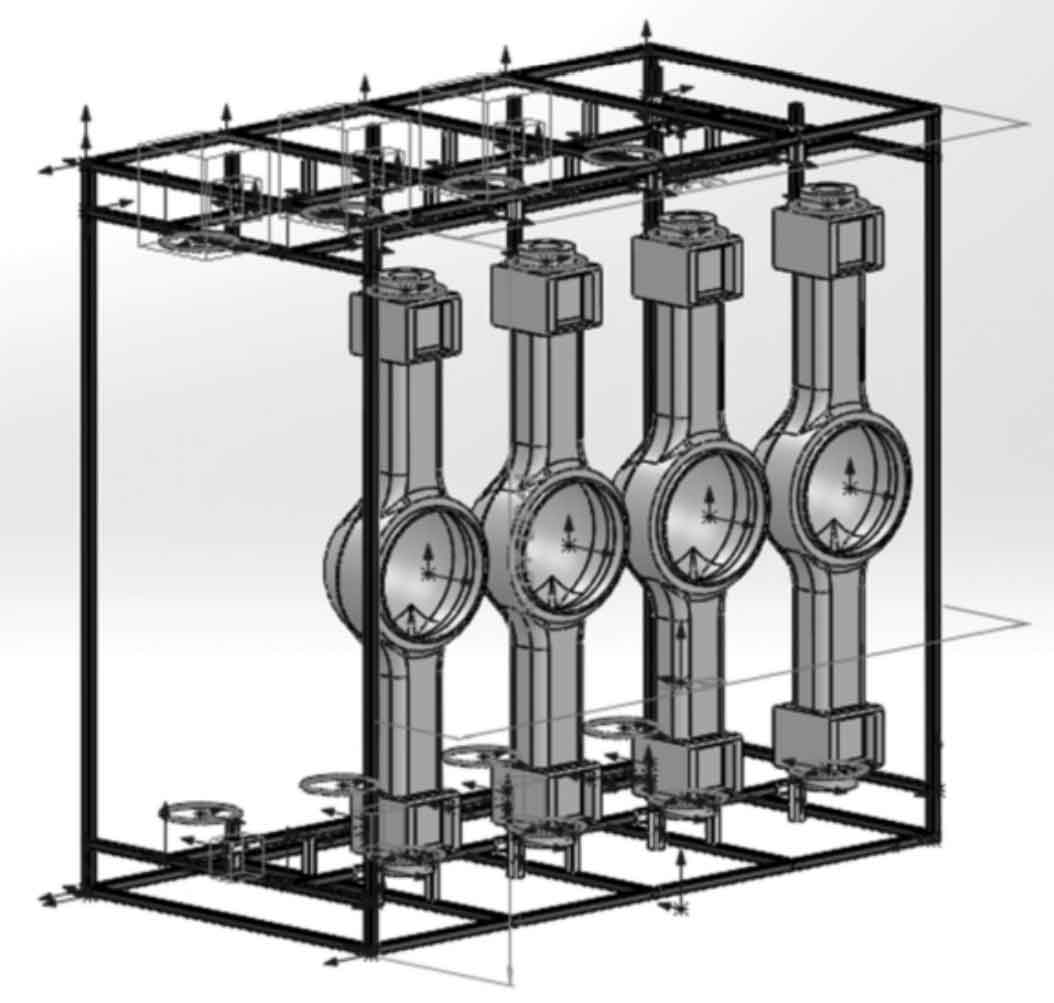

In order to prevent the white mold from deformation during coating drying, a special axle housing drying frame is designed. As shown in Figure 3.

During the last two coats of coating, due to the thickness of the overall coating, the center of gravity offset, and the white mold deformation exceeding the standard, after repeated verification, the coating drying rack in a group of 8 was changed to a group of 1, and supported in four directions at both ends and both sides. There was no deformation after coating drying.

The thickness of white mold coating is 3 ~ 4 mm in the inner cavity and 2.0 ~ 2.5 mm outside. Such coating takes into account air permeability and prevention of box collapse. The inner cavity of the axle housing is a suspended sand core. The coating thickness not only increases the strength, but also reduces the air permeability. A local high negative pressure area is formed in the inner cavity to enhance the support of the sand core to avoid box collapse. At the same time, it will also help oxygen to enter the cavity without being immediately removed by negative pressure, increasing the speed of foam combustion.