Casting refers to injecting liquid alloy into the mold to cool, solidify and carry out post-treatment, and finally become a production method of metal products. It is one of the most commonly used production processes for parts blank. It has many characteristics. It is not limited by the quality, size and shape of parts blank. The shape is very complex, and it is very difficult to be machined, or even difficult to make parts, Can be obtained by casting. According to different molds, it can be divided into sand casting, metal casting (including die casting), special casting, etc. Different casting methods have different requirements for process equipment. The mold used in sand casting is generally composed of sand mold and mold core. The raw material directly forming the mold is mainly sand, and the liquid metal completely fills the whole mold cavity by gravity to produce castings in the sand mold. Because the sand mold casting materials are cheap and easy to obtain, the mold manufacturing is simple, and the single piece production Both batch production and mass production can adapt.

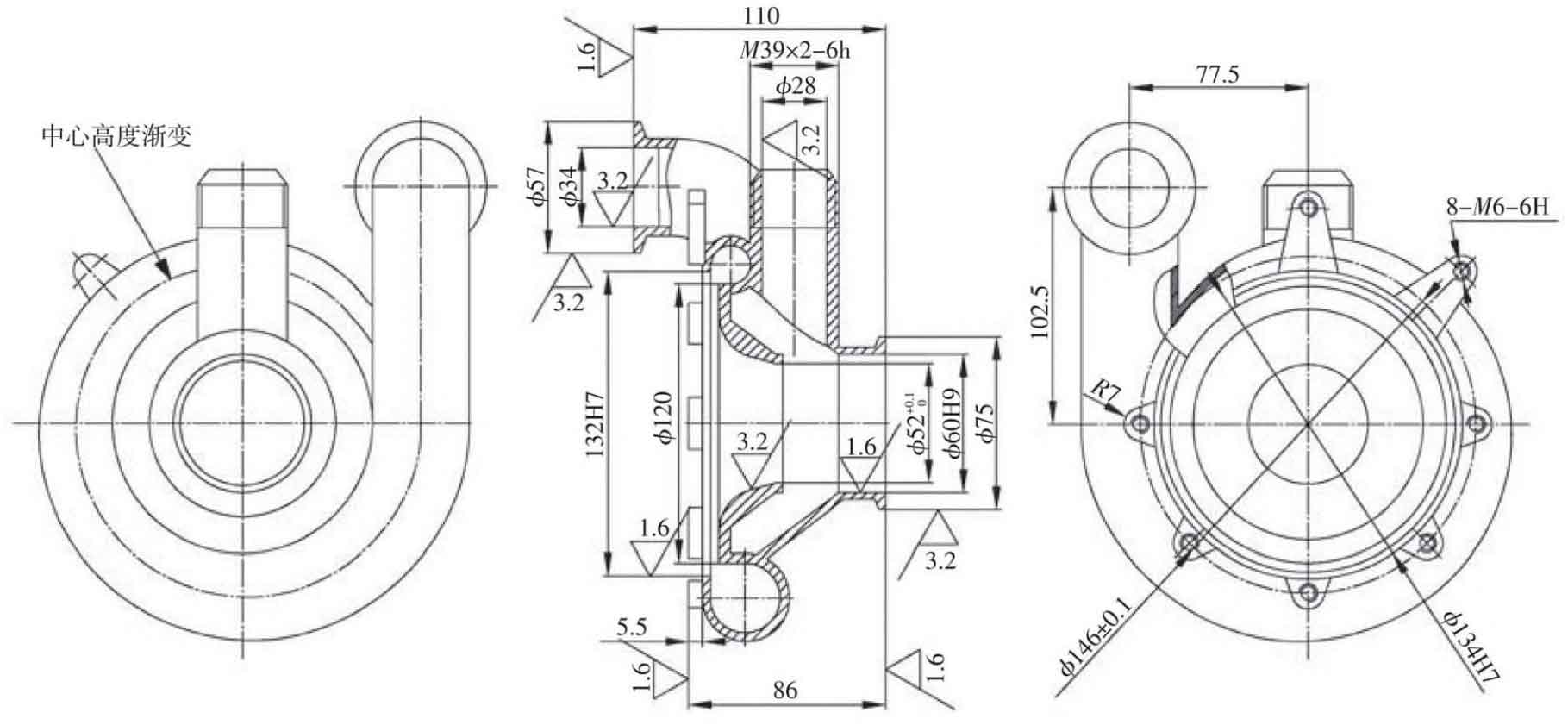

As shown in Figure 1, the structure of turbine cover parts is complex and the batch is moderate. It is formed by sand casting. The material is cast aluminum alloy with wide crystallization temperature range. The alloy tends to volume solidification, which is easy to produce dispersed shrinkage and porosity in the sand casting,. The structural features of the parts are as follows: the overall uniform wall thickness is 4mm, the center height of the volute part is a gradual curve, the right end of the volute is provided with an elbow flange with a downward length of 70mm, and the center of the volute is provided with a straight pipe parallel to the horizontal section of the elbow; There are 8 evenly distributed bosses at the bottom of the spiral case, and the inner side of the spiral case is provided with a horn structure. Its wall thickness changes gradually, and the thickest part is 14mm. The turbine cover is a hydraulic part, and the internal quality of sand casting blank shall meet the requirements of air tightness test.

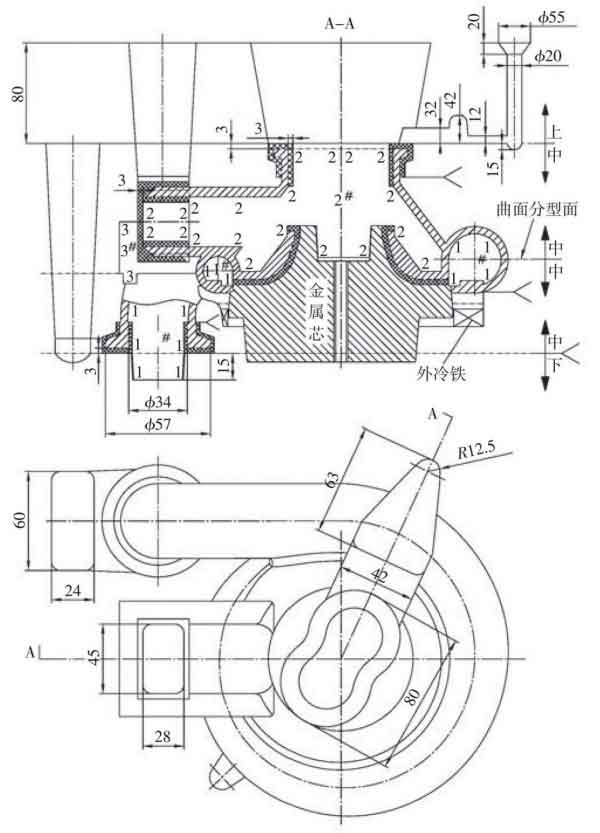

The structure of the part is complex. It is considered to use sand casting to form the casting blank, as shown in the sand casting process diagram of turbine cover in Figure 2. The sand casting needs to adopt multi box modeling. During sand casting, 8 bosses face down, 3ram machining allowance is considered for each machining surface, and the top flange, elbow flange, straight pipe, inner bell mouth and 8 bosses are thermal nodes, Feeding shall be considered. The top flange adopts the top riser, the elbow flange adopts the concealed riser, the end face of the straight pipe adopts the side riser, the inner bell mouth adopts the metal core, and the 8 convex tables adopt the external chill to realize directional solidification and eliminate the defects of sand mold casting.

According to the complex structural characteristics of the sand casting of the turbine cover, the sand casting method is adopted for molding, the pattern, false box and sand core mold are reasonably designed, the parting surface of the sand casting is simplified, and the metal core molding and local external cold iron design are adopted to avoid the occurrence of sand casting defects such as shrinkage porosity and insufficient pouring of the sand casting. The mold structure is simple, the molding cycle is shortened, and the quality of sand castings is high. The mold has been put into mass production of sand castings and has been recognized by customers.