1. Cause analysis

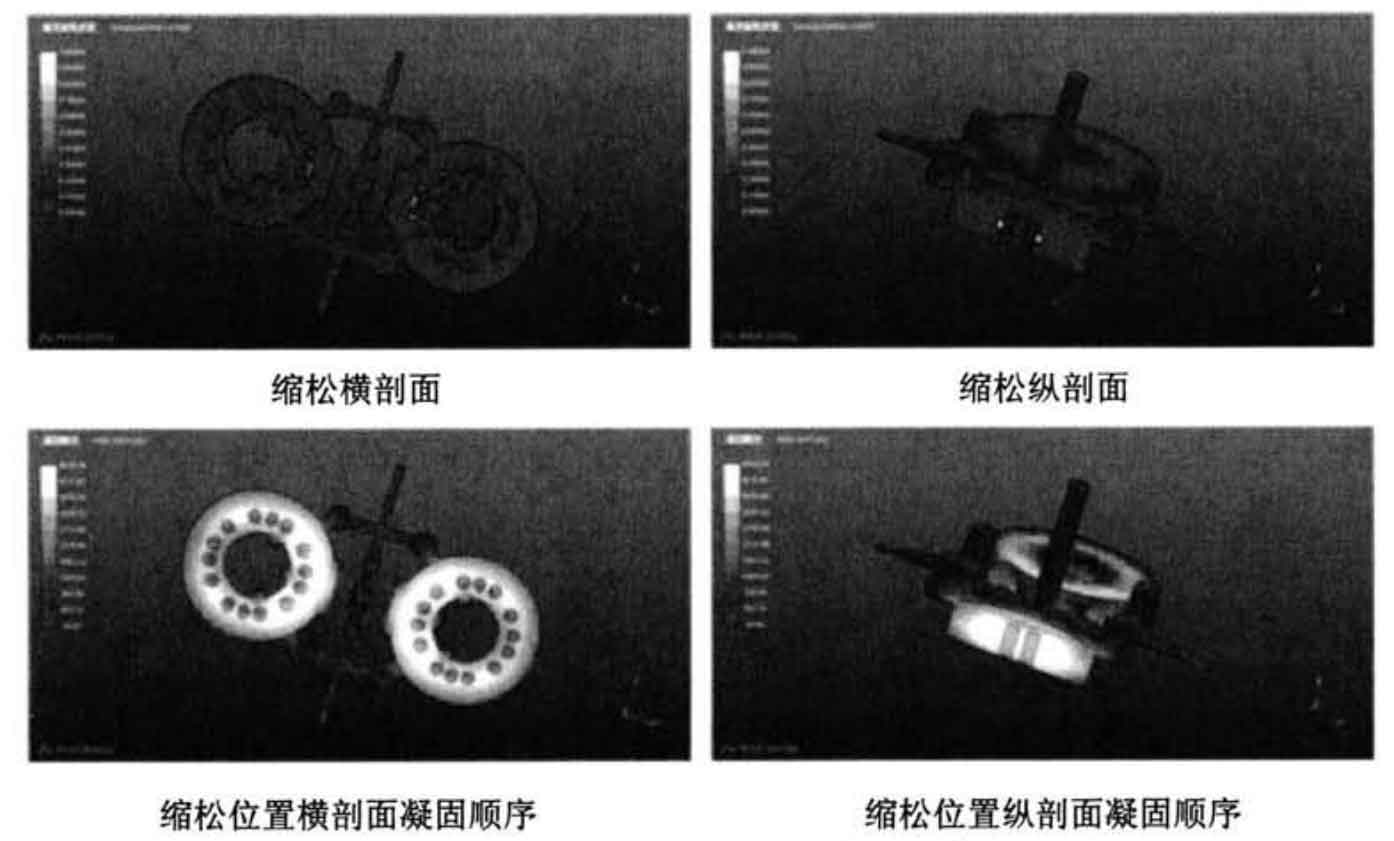

After preliminary analysis, it is concluded that the main problem in the simulation results of tooling gating riser system under existing parameters is the high probability area of shrinkage and looseness as shown in the figure. Here, the causes of the high probability area of shrinkage defect are analyzed in detail, and various causes leading to the defect are analyzed in detail. Then, on the premise of taking into account the forming quality of the weak links in the structure of sand casting coupling parts as much as possible, the optimization measures are designed to eliminate the existing high probability area of sand casting coupling parts.

It can be seen from the solidification sequence diagram of the shrinkage position section of sand casting coupling parts that the main shrinkage high probability area appears in the cavity close to the sprue, and there are three main reasons for analysis; 1. The feeding distance of the riser is not enough, resulting in that the feeding liquid metal does not extend to the shrinkage center area. 2. The thickness of the casting blank here is large due to the convex structure. 3. The shrinkage porosity area exists in the middle of the position where the molten metal is introduced into the casting cavity and close to the sprue, resulting in high local temperature and too lagging cooling. (this can be seen from the fact that the color of the outer edge of the convex part of the casting is brighter than that of other outer edges in the solidification sequence diagram.) There is a very small volume shrinkage and porosity high probability area at the far end of the sprue. Look at the cloud diagram of solidification sequence. This is not the latest solidification part of sand casting coupling parts, but there are still problems. The reasons are analyzed; Although the location of this area is far away from the molten metal introduction position and solidification is relatively early, this part is not well affected by the liquid replenishment effect of the inner sprue and riser. Moreover, this defective part is the position where the relative solidification of the local area is the latest. Therefore, it is not enough to solve the shrinkage problem only by the eutectic expansion of nodular cast iron in the solidification stage.

2. Optimization measures

For these reasons, taking the large volume shrinkage area near the sprue as the main contradiction and taking into account the small volume shrinkage defect at the far end, there are a variety of optimization measures to choose. For example;

1.The position where the molten metal is introduced into the cavity can be changed and the height of the ingate can be moved down, which is more conducive to the feeding effect of the riser and ingate. However, in order to keep the effective height of the riser unchanged, the riser size needs to be increased and the position of the parting surface needs to be changed, which makes the sand mold making more complex.

2.Lengthen the length of the inner sprue to make the mold cavity of sand casting coupling parts farther away from the sprue, reduce the influence of sprue temperature on the temperature distribution in the casting cavity and improve the temperature distribution in the mold cavity. This measure can improve the shrinkage defects in both parts, and slow down the initial speed of liquid metal into the mold cavity of sand casting coupling parts. However, increasing the length of the inner sprue will increase the heat loss of liquid metal mold filling. In this subject, the pouring strategy of “high temperature fast pouring” is adopted, which will reduce the mold filling capacity of liquid metal slightly due to increasing the heat loss of liquid metal, which will not have a substantial impact on obtaining high-quality castings.

3.Rotate the layout position of the mold cavity of the sand casting coupling parts horizontally by 180 degrees, so that the rough part with boss of the sand casting coupling parts can be turned to the outside and away from the inner sprue and sprue. This measure is the easiest to implement, but the effect is not necessarily obvious when used alone.

4.At the upper part of the area with high probability of shrinkage and looseness of sand casting coupling parts, a thermal insulation riser shall be set a little distance away from the central area of the hot joint, and the vertical liquid replenishment shall be carried out for this part. This measure requires the use of thermal insulation riser shell, which increases the production cost. Furthermore, according to the results of part stress analysis in Chapter 2, it is not suitable to adopt optimization measures such as thermal insulation riser and cold iron because there are many porous structures on the upper and lower parts of the casting blank.

5.Embed cold iron in sand core 2 to move the last solidified part of sand casting coupling parts outward. Or set cold iron directly below the defect area to move up the last solidification part of sand cast coupling parts. Both methods of embedding cold iron can improve the feeding effect of the existing riser. However, this measure also increases the production cost and the complexity of core making. In addition, the buried cold iron area is prone to the risk of other defects, especially the position of the second buried cold iron is just at the weak position of sand casting coupling parts analyzed in Chapter 2, so it should not be considered.

6.Properly reduce the pouring temperature and reduce the liquid shrinkage of liquid metal. This measure is also beneficial to both parts. The disadvantage is that the filling capacity of molten metal will be reduced as increasing the length of ingate.