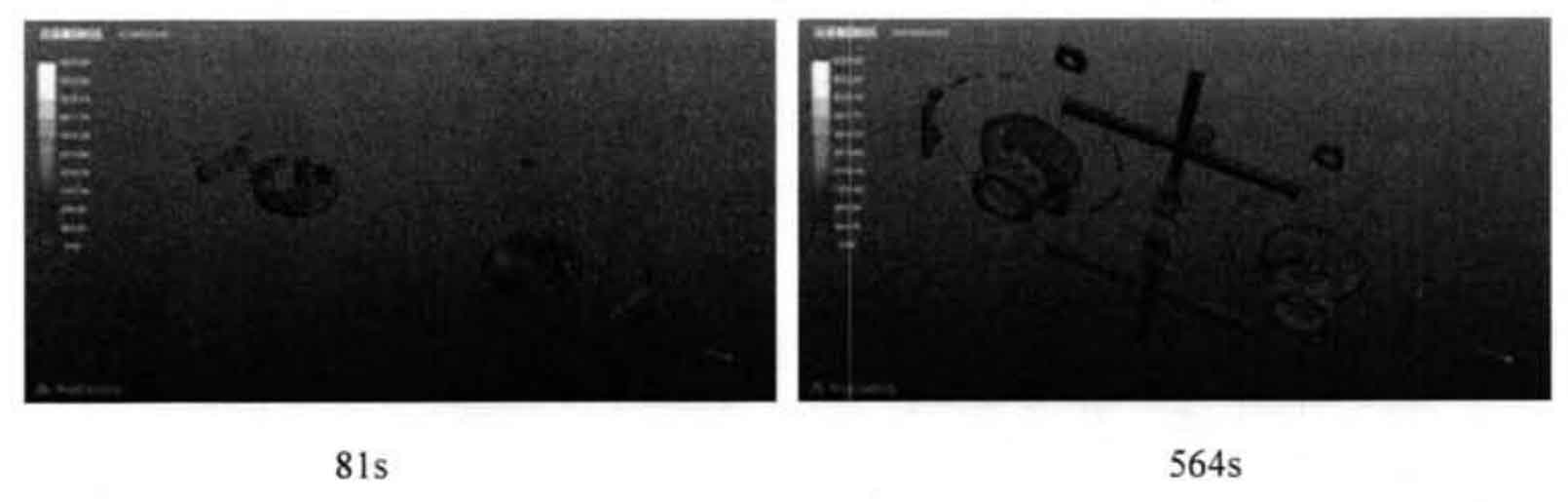

The figure below is a cloud diagram of local solidification time of sand casting coupling parts. At 81 seconds, the part near the cold iron in the mold cavity of sand casting coupling parts solidified first. At 564 seconds, the lowest thin-walled structure of sand cast coupling parts solidified. It can be seen that although the lowest end of the sand casting coupling parts is filled first when filling for about 5 seconds, and the metal liquid submerges the height of the upper surface of the cold iron only when filling for about 14 seconds, the metal liquid around the cold iron solidifies much earlier than the bottom of the sand casting coupling parts, which suggests that attention must be paid not to block the feeding channel when designing the cold iron.

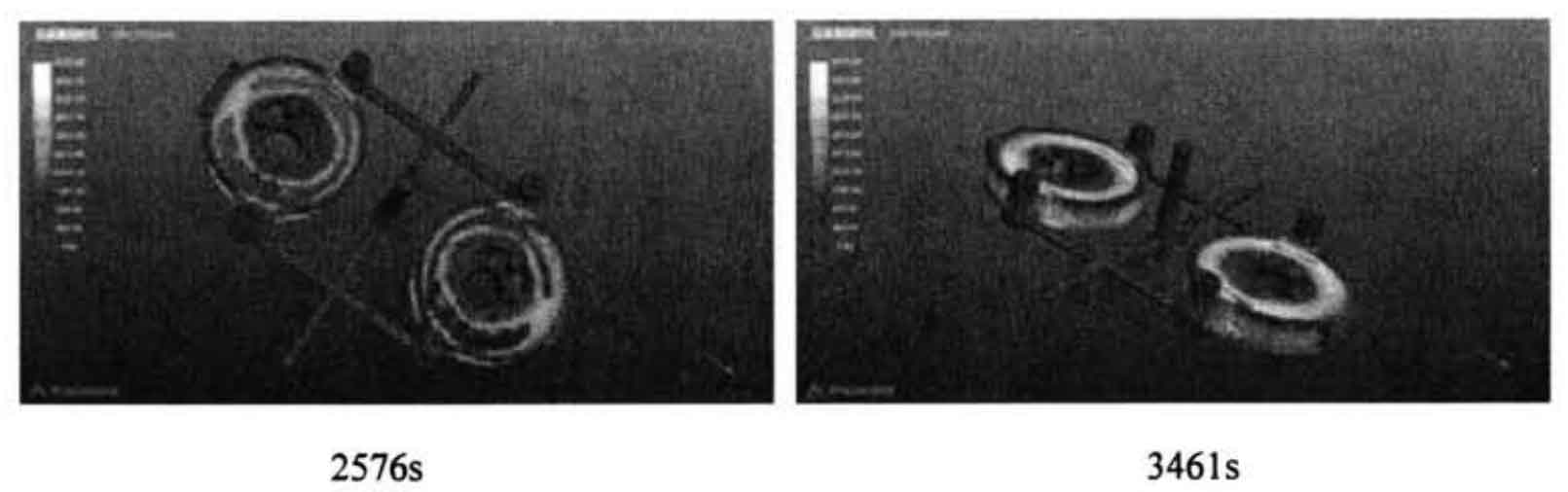

For example, due to the author’s insufficient consideration in designing the annular cold iron, the feeding channel was blocked due to the high height of the annular cold iron in an optimization, resulting in shrinkage porosity defects in the thin-walled part at the bottom of the mold cavity of sand casting coupling parts. At 2576 seconds, most of the mold cavity and sand mold of the sand cast coupling parts and around the sand core 2 have solidified. At 3461 seconds, the solidification of the two risers is completed. At this time, there are still a few areas near the riser and close to the upper plane that are not solidified. However, when checking the shrinkage porosity defects, this part is also the area with high probability of shrinkage cavity and shrinkage porosity. It is speculated that these areas are finally filled by the self feeding of nodular cast iron due to eutectic expansion in the whole solidification stage. Finally, at 4035 seconds, the mold cavity of the whole sand casting coupling parts solidified tightly.