It is difficult to obtain accurate input parameters in sand casting simulation. For material properties, although sand casting simulation software has a fairly perfect material database, there are often slight or considerable differences between the materials used in the factory and them. The physical properties of materials are very sensitive to trace elements, even if the chemical composition is similar, it is often difficult to judge the correctness of their attribute parameters. In addition, the data of the relationship between temperature and solid fraction is not particularly perfect. For example, the critical solid fraction of liquid metal that can pass through dendrites or feed will change with the morphology and distribution of solid phase. It is not only affected by chemical composition, but also related to fluid flow, solidification conditions and pregnancy treatment. The solidification and liquid shrinkage data of the alloy are not perfect. The criteria for shrinkage defects, such as niyama criterion, will not only change due to the chemical composition, but also be affected by the shape and size of the casting. Especially for the shrinkage defects in nodular cast iron, even if the chemical composition is similar, these data can not be used well, because it is accompanied by graphite expansion during solidification, Although we have developed a sand casting simulation software that can distinguish defects by tensile stress in paste zone, we need to determine the critical stress by experience combined with casting alloy and mold strength. Many physical properties of a material depend not only on its chemical composition, such as the surface tension of liquid metal, the wetting angle between liquid metal and mold, etc. Due to the different chemical composition and density of molding sand, the characteristics of molding sand used in each factory vary greatly and will change over time. For example, since the thermal conductivity is affected by the surface density, it will change with the forming conditions and mold position. For another example, the gasification and condensation of water in the mold also affect the thermal and mechanical properties.

Initial conditions such as pouring temperature and speed, mold surface conditions will change with time and affect the filling and solidification process of castings. The thermal resistance between casting and mold will change due to the flow of liquid metal, the formation of gas, the deformation of solidification area, etc. Although the data of thermal resistance have been published, it can not be guaranteed that these data can be universal, because the casting conditions and cavity shape are usually different. Therefore, we usually use the data obtained from the measured temperature or the database provided by the software. Even so, it is difficult for us to ensure the accuracy of the data used. In addition, although the estimation method of thermal resistance has been published, it is difficult to be applied to practical casting, especially sand casting.

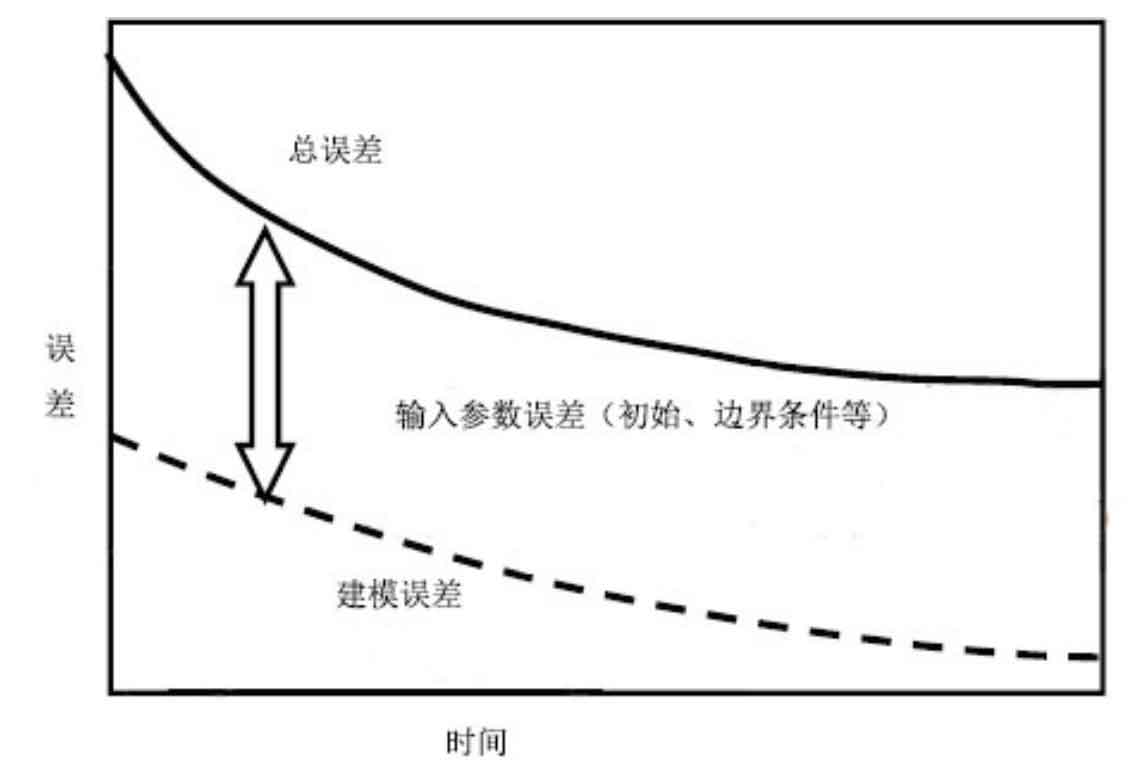

The accuracy of sand casting simulation software itself is also difficult to verify, because the goal of sand casting simulation is unknown complex physicochemical phenomena. Therefore, in the software testing stage, the software verification is usually completed by comparing the limited measurement data with the sand casting simulation results. However, the software can not be guaranteed to have sufficient accuracy in sand mold casting simulation, because the data used for verification will be wrong due to measurement, input data error and fluctuation of actual phenomena. In addition, when the simulation conditions of sand casting are different from those used for verification, the equivalent accuracy of the software can not be guaranteed. The accuracy of sand casting process simulation is more difficult to judge, because the influence of error accumulation on the final result has not been fully studied. Sensitivity analysis may be a method to evaluate accuracy, but it becomes more difficult with the increase of input data. Although the modeling errors may become smaller due to the improvement of technology in the future, as shown in the figure, the errors of input data such as initial conditions and boundary conditions cannot be reduced.