The mud pump body of sand casting is made of ZG35, which belongs to medium carbon cast steel, with high melting point, narrow crystallization temperature range, large shrinkage during solidification, easy oxidation, shrinkage porosity and other defects during solidification. Therefore, the sand casting pouring system of the mud pump body is required to have simple structure, large cross-sectional area, fast and stable mold filling, and the rising speed of liquid level should be appropriate.

To produce sand castings with good quality, it is necessary not only to design reasonable sand casting process and adopt advanced casting equipment, but also to have a structure suitable for sand casting production.

In the actual production of sand casting, some castings with unreasonable structural design are often encountered, which brings great difficulty to the production, and some are even difficult to produce; Although some can be produced, they can not guarantee the quality of castings. Therefore, the casting not only needs to meet the machining requirements and the service performance requirements of the casting itself; It also needs to meet the requirements of sand casting production, namely “casting processability”.

In order to make the castings have good sand casting processability, in the traditional sand casting production process, the product structure engineer and casting process engineer mainly cooperate with each other to analyze the processability of the castings with experience before designing the sand casting process scheme. This method, which relies heavily on production experience, is difficult to accurately analyze the casting process. The unreasonable part design is difficult to be found, and can only be found after many production practices. Recently, with the rapid development of Computer Aided Engineering (CAE), the sand casting technology, which relies heavily on experience, has undergone a great change to modern and scientific. Engineers and technicians can use the sand casting numerical simulation software to analyze the sand casting process, establish a scientific basis and improve the part structure.

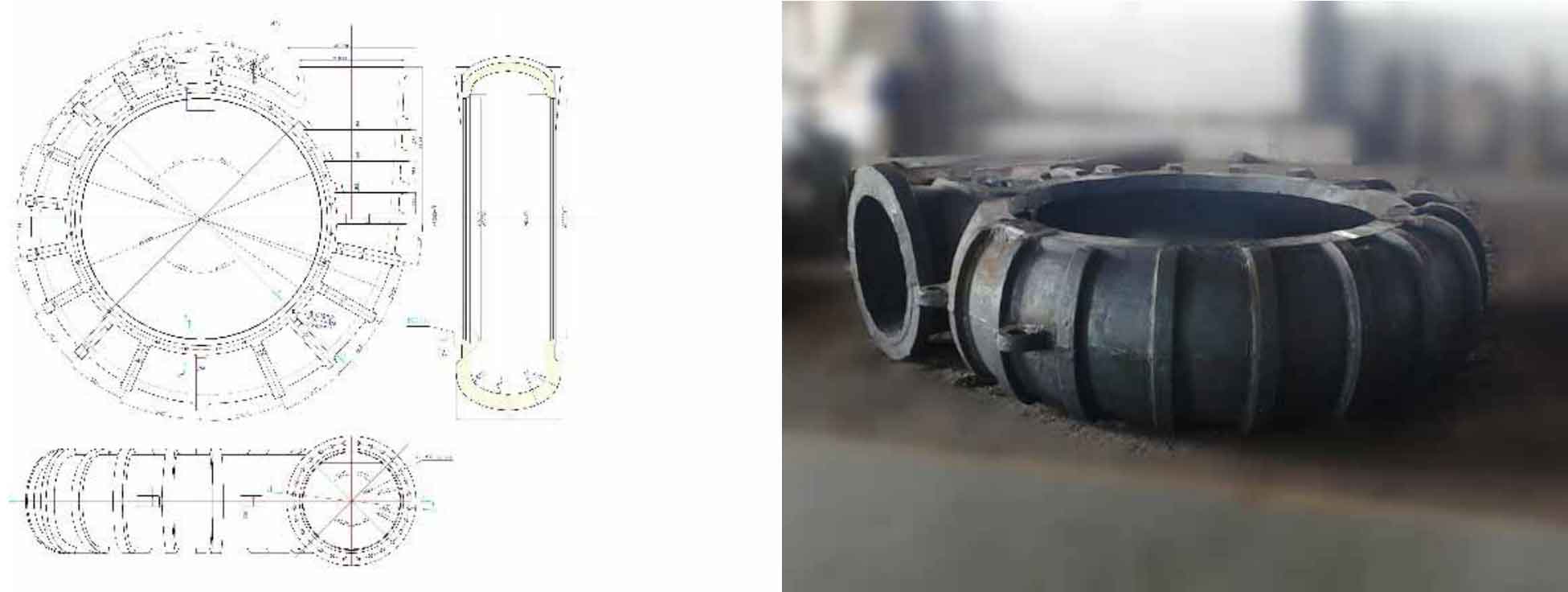

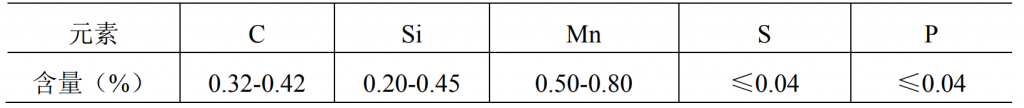

The structure of the mud pump body of sand casting is shown in the figure. The mud pump body adopts ZG35 medium carbon cast steel, and its chemical composition is shown in the table.

The filling capacity and fluidity of liquid cast steel 35 are related not only to its chemical composition, but also to the shape and structure of the mud pump body. When the minimum wall thickness of sand casting is too small, the molten metal will not be able to fill the mold, resulting in defects such as insufficient pouring and cold shut. Therefore, in the structural design of sand castings, it is necessary to ensure that the designed minimum wall thickness is greater than the minimum wall thickness that the sand casting material can fill the mold. The main wall thickness of sand casting mud pump body is 85mm, the minimum wall thickness is 75mm, and the maximum outline dimension is 3595mm × 3376mm × 1240mm, the minimum wall thickness of sand casting mud pump body is greater than that of sand casting ZG35 casting, and the wall thickness dimension design of sand casting is reasonable.

Mud pump body is a large curved surface pump body sand casting, which is prone to sand inclusion, deformation, crack and other defects in the process of sand casting. In order to improve the casting quality of sand casting mud pump body, a large number of stiffeners are set on the external surface of the pump during the structural design of sand casting. The design of stiffener structure can not only effectively prevent sand inclusion, deformation, crack and other defects of sand castings, but also improve the mechanical properties of sand castings and reduce the weight of sand castings.

There are often many holes in the product part drawing. From an economic point of view, we hope to cast these holes as much as possible during sand casting, which can reduce machining and save cost. However, because the size of some holes on the parts is too small, it needs more precise sand casting process to cast, and sometimes the cast holes are eccentric, which can not meet the machining accuracy. Therefore, the possibility, necessity and economy of hole casting need to be considered whether the hole on the part is cast or not. The diameter of the threaded hole on the end face of the casting mud pump body is 30mm, and the size of the hole is less than the size of the minimum cast hole. Therefore, these holes should not be cast during casting production. However, the diameter of the hole on the lifting ring of the mud pump body is 60mm, and the size of the hole is larger than that of the minimum cast hole. Therefore, these holes should be cast during sand casting.