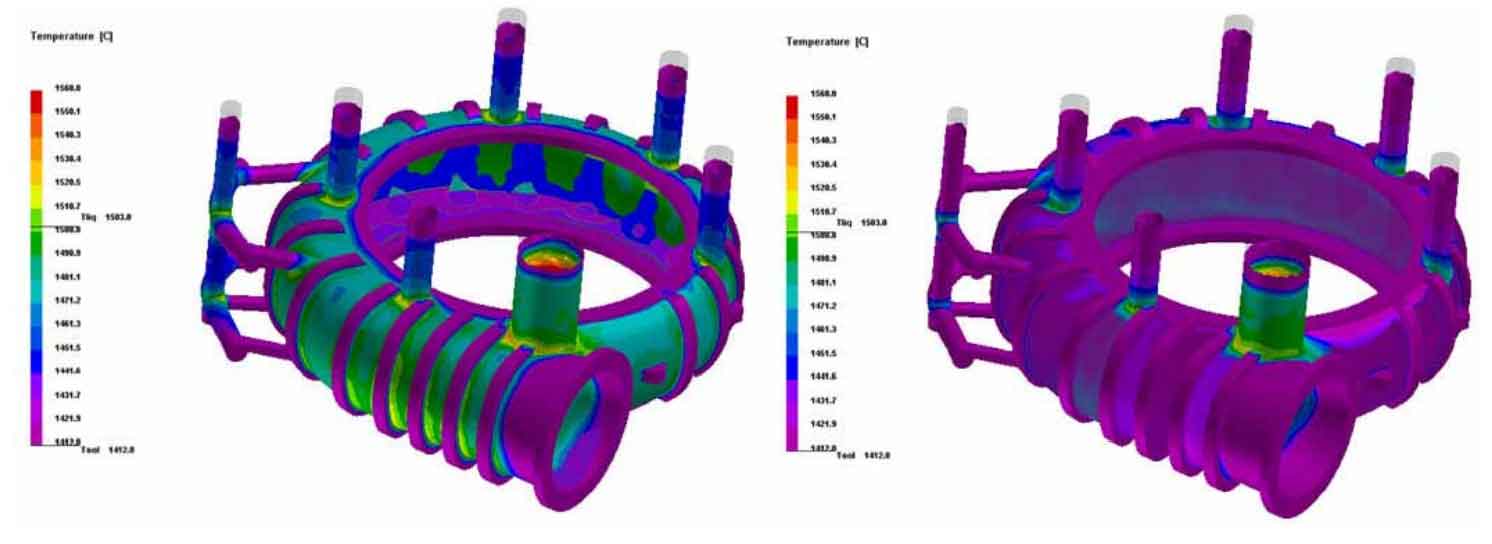

Figure 1 shows the simulation results of temperature field at each time during solidification of mud pump body in sand mold casting. Due to the chilling action of the cold iron, the temperature of the stiffener of the casting drops below the solidification line just after the pouring and begins to solidify. The temperature drop of the casting in the middle of the #2-2 riser and #2-3 riser is more obvious than that of the surrounding parts, which has taken the lead in solidification. The temperature drop in the lower half of the flange is greater than that in the upper half, which has begun to solidify. At the same time, under the action of the cold iron, The bottom temperature of the casting is lower than the top temperature, which has basically formed a bottom-up temperature gradient distribution towards the riser; With the continuous solidification of sand mold casting mud pump body, the temperature of the lower half of the stiffener and flange continues to decrease, and the solidification of sand mold casting mud pump body is in progress. When the solidification is 50%, the temperature of the stiffener has dropped to the solidus line and basically completed the solidification. At this time, the temperature at the bottom of the casting has also dropped below the solidus line and began to solidify, The upper half of the casting still maintains a high temperature and is basically not solidified. The temperature of the lower half of the flange has been basically reduced to the solidus line. The solidification of the mud pump body of sand mold casting has been basically completed, and the temperature of the upper half of the flange has been lower than the solidification line and is solidifying; When 70% of the solidification is completed, the flange is basically solidified, and the temperature of the lower half of the casting is close to the solidus line, which is about to complete the solidification of the mud pump body of sand mold casting. However, under the action of subsidy, the metal liquid at the #1 riser and #2-1 riser root still maintains a high temperature. At the same time, due to the addition of insulating sleeve and insulating agent to the riser, the metal temperature in the riser is still higher than the solidification line and remains liquid, The riser also has feeding effect; When 85% of the solidification is completed, the pump body of the sand mold casting mud pump has solidified, and the metal temperature in the riser is between the liquidus and the solidus. It is solidifying, but at this time, the riser neck has been completely solidified and the feeding process of the riser is completed.

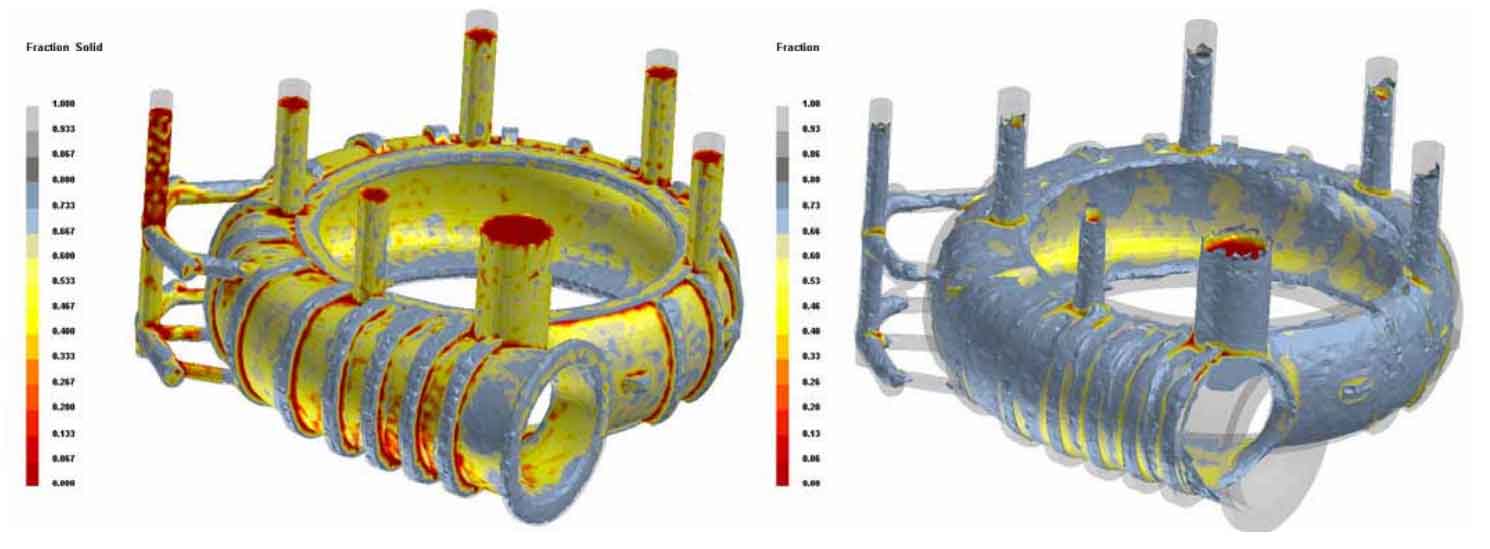

Figure 2 shows the distribution of solid phase rate of sand mold casting mud pump body and pouring riser during the solidification of sand mold casting mud pump body. It can be seen from the distribution diagram of solid phase rate that when the solidification is completed by 20%, the solid phase rate value of the stiffener and the lower half of the flange of the casting has been very high, and the metal is solidifying, but the solid phase rate of the main part of the casting is less than 10%, and the metal is still in the liquid state and basically not solidified; When the solidification of the pump body of sand mold casting mud pump is completed by 50%, the solid rate of the lower half of the casting stiffener and flange has been higher than 70%, and the solidification is basically completed. At this time, the solid rate in the middle of #2-2 riser and #2-3 riser has exceeded 70%. The liquid metal between the two risers has been separated and solidified towards their risers respectively, and the solid rate on the surface of the casting is also rising, The casting has begun to solidify; When 70% of the solidification of the mud pump body in sand mold casting is completed, most areas of the casting have solidified, and the liquid metal has separated to form multiple liquid phase areas, but the liquid phase area basically surrounds their risers and the riser neck has not solidified. At this time, the risers feed to each liquid phase area, reducing the possibility of shrinkage defects; When 85% of the solidification of the sand mold casting mud pump body is completed, the solid rate of the casting body has exceeded 70%, but the solid rate inside the riser is only about 50%, and the solid rate in the central area of the riser is less than 30%, but the solid rate at the root of the riser is more than 70%, indicating that at this time, the casting body and the root of the riser have been completely solidified, and the feeding has been completed although the riser has not been completely solidified, The riser is the final solidification area, and the simulation results of solid rate are consistent with the analysis results of temperature field.

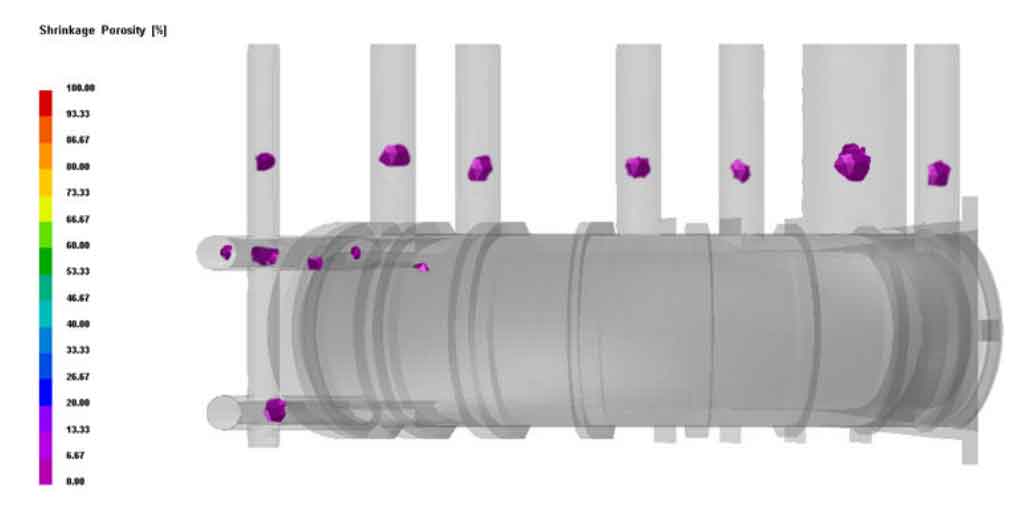

It can be seen from the simulation results in Figure 3 that the shrinkage defects of the sand mold casting mud pump body during solidification are mainly concentrated in the riser and inner sprue, and there are almost no shrinkage defects in the casting body, indicating that the riser has well fed the casting during the solidification of the sand mold casting mud pump body under the cooperation of cold iron, The final quality of the casting is guaranteed. The optimized process scheme can effectively eliminate the shrinkage defects caused by the previous process, and greatly improve the casting quality of sand mold casting mud pump body.