ADC12-0.25ti aluminum alloy samples for automotive castings were prepared at different pouring temperatures. The microstructure, fluidity and hot cracking resistance of the samples were tested and analyzed. The main conclusions are as follows:

(1) Pouring temperature has an obvious effect on the microstructure and casting properties of adc12-0.25ti aluminum alloy. With the increase of pouring temperature from 690 ℃ to 750 ℃, the microstructure of the sample was basically unchanged at first and then coarsened sharply, the fluidity was gradually improved, and the hot cracking resistance was first improved and then decreased.

(2) When the pouring temperature is 690 ℃, the aluminum melt flow is the shortest; When the pouring temperature is 750 ℃, the aluminum melt flow is the longest, which increases by 71mm compared with 690 ℃.

(3) When the pouring temperature is 720 ℃, the crack length of the sample is the shortest, which is 2.9 mm less than that of 690 ℃; When the pouring temperature is 750 ℃, the crack length of the sample is the longest, which increases by 3.4 mm compared with 690 ℃.

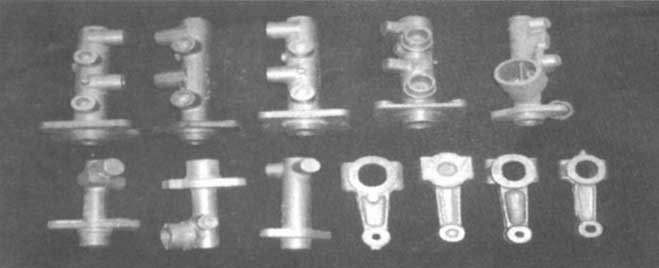

With the acceleration of automobile lightweight process, aluminum alloy is more and more widely used in automobile industry. People have done a lot of research on automotive aluminum alloys and have made a lot of research results. Suoxiaojuan et al. Analyzed the effect of electromagnetic casting stirring frequency on the microstructure and properties of A356 aluminum alloy for automobile. Yu Wentao and others optimized the low pressure casting process of aluminum alloy automobile hub based on neural network technology. Li Yu et al. Studied the wear resistance of a new Al Si mg series cast aluminum alloy for automobile wheels. Weixiankun studied the optimization of slow injection process parameters for automotive aluminum alloy die castings. Xie Wenlong et al. Studied the hot compression deformation behavior of cast aluminum alloy for automobile engine and constructed the phenomenological constitutive equation. Qian Dongling and others summarized and analyzed the research progress of cast aluminum alloy for automobile chassis. Pangluoming et al. Developed the robot integrated system for low pressure casting of automotive aluminum alloy cylinder. Huangmeilian et al. Designed the die casting die for the aluminum alloy lower cylinder block of automobile engine. Gong Tao et al. Studied the casting properties of ZL205A aluminum alloy for automobile hub. Cuilong et al. Designed the die-casting die of aluminum alloy for automobile variable shell. Today, with the increasing requirements of the automotive industry for the properties of aluminum alloys, the development of new aluminum alloys for automotive castings is becoming more and more urgent. We all know that adding a small amount of titanium to aluminum alloy can significantly refine the grain structure of aluminum alloy, improve the mechanical properties of the alloy and reduce the hot cracking tendency of the alloy. However, there is little research on new aluminum alloys containing titanium at present. Therefore, the microstructure and casting properties of titanium containing ADC12-0.25ti aluminum alloy for automotive parts were studied in order to provide experimental data support for the development of new aluminum alloys for automotive castings.