At present, the coupler knuckle used in the couplers of China’s railway freight cars is cast coupler knuckle. The cast coupler knuckle is an integral casting part with complex structure, and casting defects will inevitably occur in the casting process. The main failure forms of the cast coupler knuckle in use are fracture and wear overrun. Fatigue crack is the main reason for the fracture of the cast coupler knuckle in service, while friction and abrasive wear are the main reasons for the excessive wear of the coupler knuckle in service.

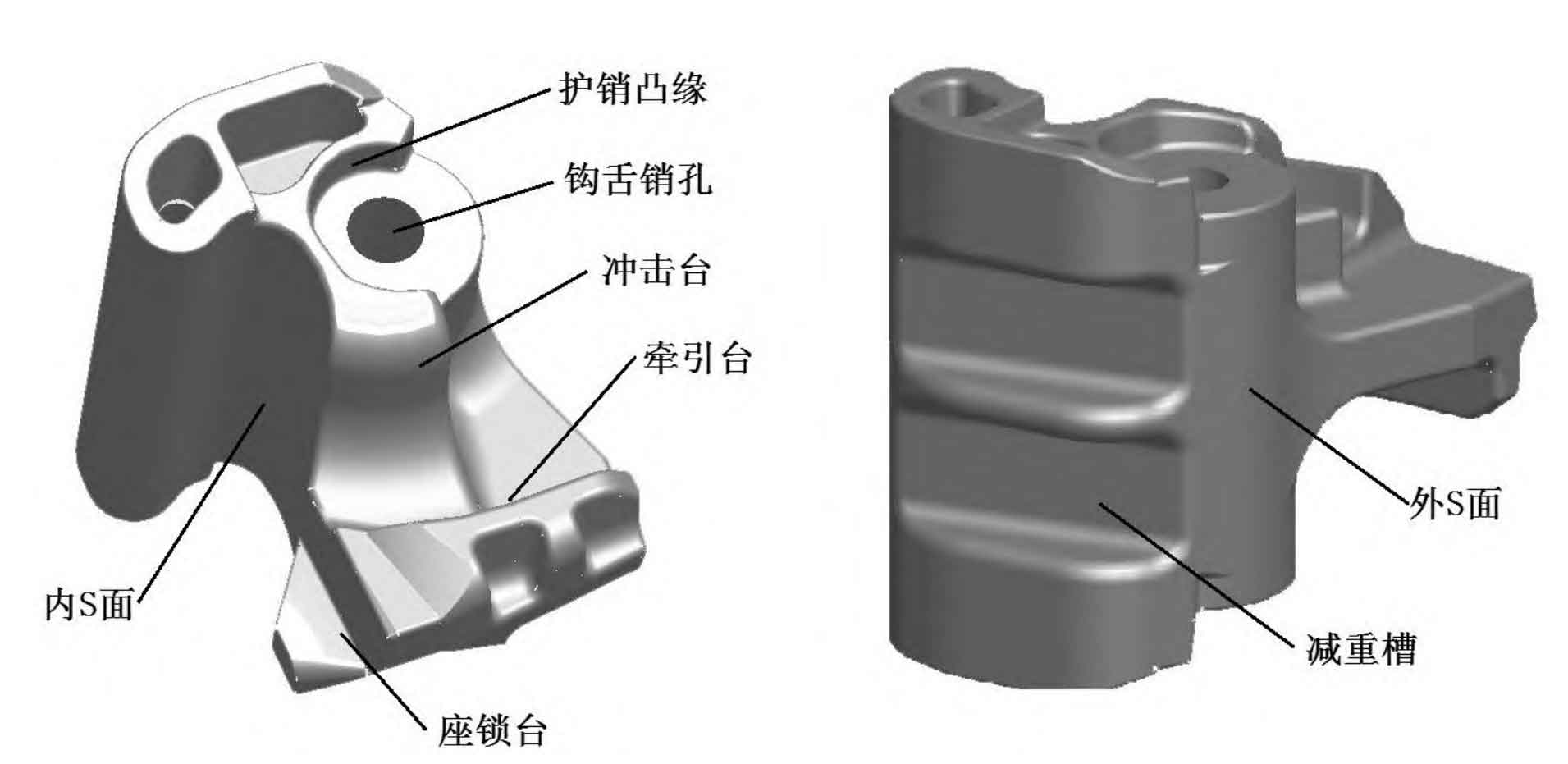

In order to improve the crack and wear overrun of the cast coupler knuckle, improve the fatigue life of the coupler knuckle and extend the service life, China has successively completed the production of F, CQ and 16D forged coupler knuckle, as shown in Figure 1. The forged knuckle is made of high-strength high-quality carbon alloy steel. The mechanical properties and fatigue resistance of the fiber structure formed by the forging process are obviously better than those of the casting structure, with high strength reserves. The service life of forged coupler knuckle is up to 6 years, which is much longer than that of cast coupler knuckle for 3 years. The forging knuckle position name is shown in Figure 2.

According to the structure and design basis of forged knuckle, vertical forging and horizontal forging can be used for forging. The process is as follows.

Manufacturing process of forging knuckle (vertical forging): blanking → heating → die forging → trimming → grinding → processing (drawing → boring → milling the locking surface → milling the inner S surface → milling the outer S surface → milling the traction platform and impact platform → milling the guard pin flange) → grinding → sample plate detection → heat treatment → shot blasting → flaw detection → painting.

Manufacturing process of forging knuckle (cross forging): blanking → heating → die forging → trimming → grinding → processing (drawing → boring → milling the locking surface → milling the inner S surface → milling the traction platform and impact platform → milling the guard pin flange) → grinding → sample plate detection → heat treatment → shot blasting → flaw detection → painting.