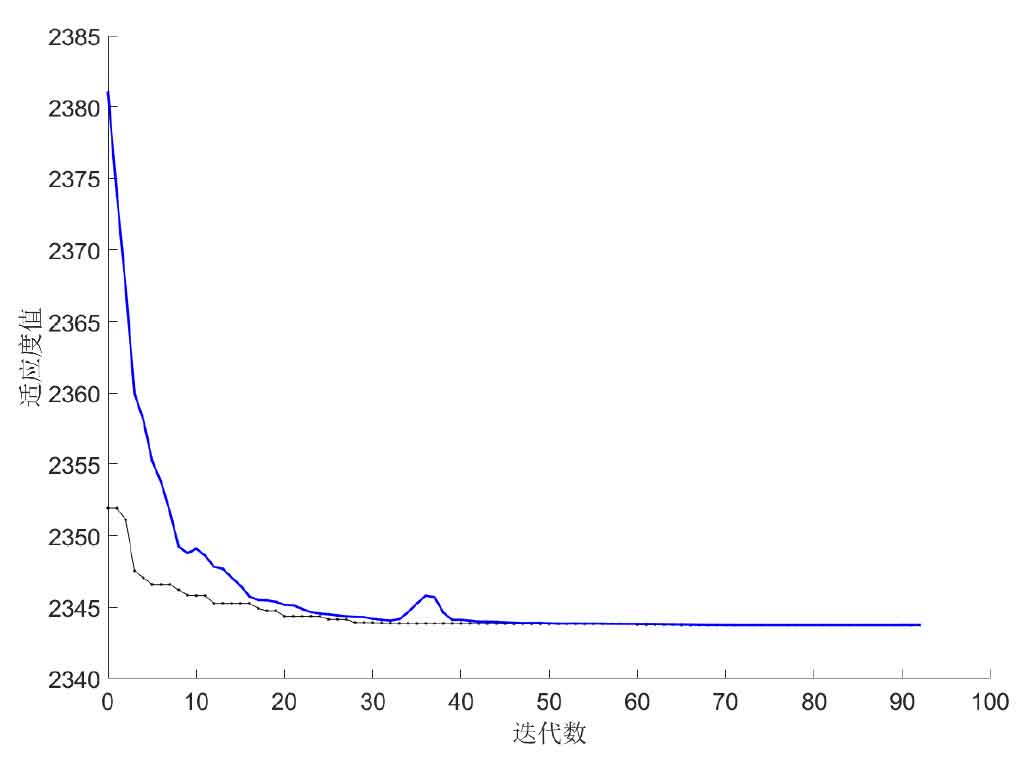

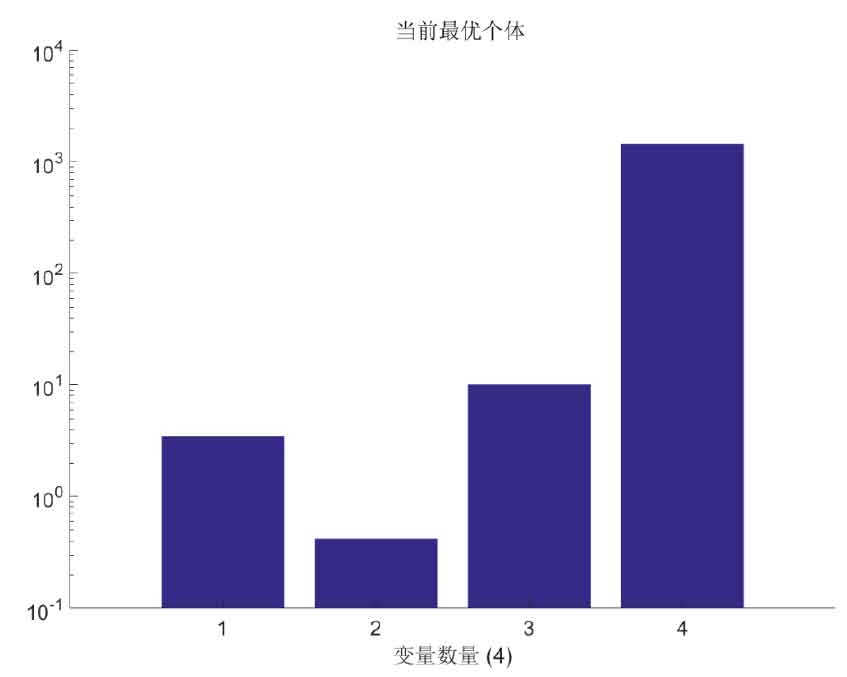

Matlab 2016b software is used for calculation. The trend of calculated fitness is shown in Figure 1, and the optimal individual value within the parameter value range in the figure is shown in Figure 2. In the early stage of iteration, the fitness value is close to the optimal value, but in the later stage, the fitness value rises again. After a certain number of iterations, the fitness value tends to be stable. At this time, the fitness value begins to approach the optimal solution. The ordinate in Figure 2 represents the value of the optimal individual. The specific variables in the optimal individual are machining allowance, draft angle, fillet radius and pouring temperature respectively. The optimal individual values are [3.5, 0.42, 101440]. The final fitness value calculation results are shown in Figure 1.

The four variables in the fitness function are changed. The four variables are machining allowance, draft angle, sand casting fillet radius and pouring temperature, which are the optimal individual values in Figure 2.

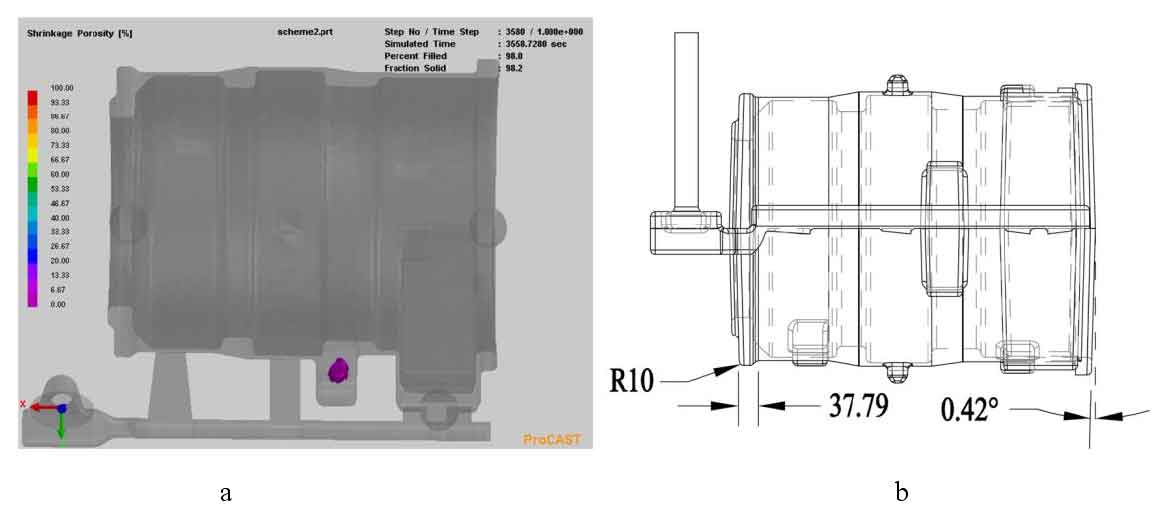

The sand casting process parameter scheme is verified with ProCAST software, and the simulation results are shown in Figure 3. The drawing of the sand casting comes from China sand casting company. The sand casting in the drawing is the shell of the central air conditioning compressor. Under the simulated boundary conditions, the filling time is 20s and the temperature is 1440 ℃. The cooling mode of the sand box is air cooling (FilmCo = 10, t = 20c), the sand mold material is resin sand and the alloy is en-gjl-250. The sand casting is completely solidified in the sand box. As shown in Figure 3a, a small amount of shrinkage cavity is mainly located on the gating system and shell base. The simulation results show that the quality of sand mold casting is qualified. Fig. 3b is the outline drawing of sand casting, and the three process parameters of machining allowance, draft angle and sand casting fillet are marked in Fig. 3B.